Crimping heat shrink terminals correctly requires three essential steps: strip the wire to the proper length, insert it fully into the terminal barrel, and apply firm, centered pressure with a crimping tool until you hear a click. The heat shrink insulation then seals the connection when heated, creating a waterproof, vibration-resistant electrical connection that meets professional quality standards.

Understanding how to crimp heat shrink terminals properly ensures reliable electrical connections that prevent wire pullout, reduce voltage drop, and protect against moisture intrusion in automotive, marine, and industrial applications.

What Are Heat Shrink Terminals?

Heat shrink terminals are electrical connectors with an integrated heat-activated adhesive sleeve that creates a sealed, insulated connection when heated. Unlike standard crimp terminals, these combine mechanical crimping with thermal sealing to provide superior protection against moisture, vibration, and environmental contamination.

Key Components:

- Metal barrel: Crimps onto the stripped conductor

- Heat shrink sleeve: Transparent or colored polyolefin tubing

- Hot melt adhesive: Inner sealant layer that melts at 194-230°F (90-110°C)

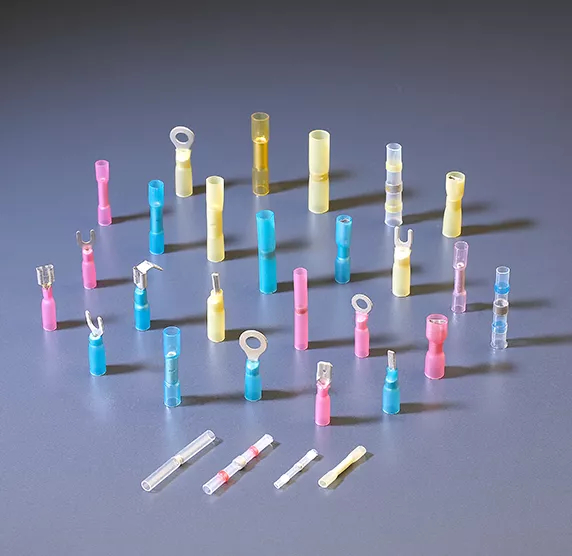

- Terminal end: Ring, spade, butt splice, or disconnect style

Heat shrink terminals are essential for applications requiring IP67 or higher protection ratings, including marine electronics, outdoor lighting systems, automotive wiring harnesses, and any connection exposed to moisture or corrosive environments.

Heat Shrink vs. Standard Crimp Terminals: Key Differences

Here is a table that shows how heat shrink terminals compare to standard crimp terminals:

| Feature | Heat Shrink Terminals | Standard Crimp Terminals |

|---|---|---|

| Moisture Protection | Waterproof seal (IP67-IP68 rated) | Minimal protection, requires separate shrink tubing |

| Installation Time | 2-3 minutes (crimping + heating) | 30 seconds (crimping only) |

| Cost Per Terminal | $0.25-$0.75 | $0.05-$0.15 |

| Vibration Resistance | Excellent – adhesive bonds to wire jacket | Good – mechanical crimp only |

| Visual Inspection | Easy – transparent sleeve shows conductor | Difficult – hidden inside barrel |

| Working Temperature | -40°F to 257°F (-40°C to 125°C) | -40°F to 221°F (-40°C to 105°C) |

| Best Applications | Marine, outdoor, automotive, corrosive environments | Indoor panels, dry environments, quick repairs |

| Rework Difficulty | Very difficult – must cut and replace | Easy – can be removed and recrimped |

💡 EXPERT TIP: Always use heat shrink terminals for any connection that will be exposed to weather, wash-down environments, or high-vibration equipment. The additional cost pays for itself by preventing callback failures.

Tools and Materials Required for Professional Crimping

Essential Crimping Tools Comparison

Here is a table that shows the different crimping tool options:

| Tool Type | Price Range | Wire Gauge Range | Best For | Limitations |

|---|---|---|---|---|

| Ratcheting Crimper | $30-$150 | 22-10 AWG | Professional installations, consistent quality | Requires correct die size |

| Hydraulic Crimper | $200-$800 | 14-4/0 AWG | Large gauge cables, high-volume production | Heavy, expensive, overkill for small wires |

| Pliers-Style Crimper | $15-$40 | 22-14 AWG | Light-duty work, occasional repairs | Inconsistent pressure, not for critical applications |

| Automatic Crimper | $500-$2,000+ | Programmable | Production environments, volume work | High initial investment |

⚠️ SAFETY WARNING: Never use standard pliers or vice grips to crimp terminals. Improper crimping creates high-resistance connections that generate heat and can cause electrical fires.

Additional Required Materials

Wire Preparation Tools:

- Wire strippers (adjustable or gauge-specific)

- Wire cutters (flush-cut for clean ends)

- Deburring tool or fine sandpaper

- Cable measurement gauge

Heating Equipment:

- Heat gun (minimum 500W, temperature-controlled preferred)

- Butane mini torch (for field work)

- Heat shrink heat station (for production environments)

Quality Control Tools:

- Pull tester (measures tensile strength)

- Digital multimeter (checks resistance)

- Wire gauge chart or caliper

💡 EXPERT TIP: Invest in a quality ratcheting crimper with interchangeable dies. The Deutsch HD-20 or Thomas & Betts ERG4000 series will handle 90% of terminal crimping applications and ensure consistent results every time.

The Complete 7-Step Crimping Process

Step 1: Select the Correct Terminal Size

Match your terminal to both wire gauge and stud/connector size. Heat shrink terminals are color-coded by wire gauge:

- Red: 22-18 AWG (0.5-0.75mm²)

- Blue: 16-14 AWG (1.0-1.5mm²)

- Yellow: 12-10 AWG (2.5-4.0mm²)

- Uninsulated: 8 AWG and larger (6.0mm²+)

Check the terminal packaging or stamping for the specific wire range. Using an oversized terminal creates a loose crimp; undersized terminals won’t accept the conductor.

💡 EXPERT TIP: When working with stranded wire at the upper end of a terminal’s range, twist the strands tightly before insertion to ensure all conductors enter the barrel.

Step 2: Strip the Wire to Proper Length

Strip the insulation to match the terminal barrel length, typically 5-8mm (3/16″-5/16″) for most terminals:

- Set your wire stripper to the correct gauge setting

- Position the stripper perpendicular to the wire

- Squeeze firmly and rotate 180 degrees to score the insulation

- Pull the insulation straight off (never twist)

- Inspect for nicked or damaged strands

Proper Strip Length Guide:

- Too short: Insulation enters the barrel, creating a weak crimp

- Correct: Wire fills barrel with no insulation inside

- Too long: Exposed conductor extends beyond sleeve, creating a shock hazard

⚠️ SAFETY WARNING: Nicked strands dramatically reduce current capacity. If more than 10% of strands are damaged during stripping, cut the wire back and restart.

Step 3: Inspect and Prepare the Conductor

Before inserting the wire:

- Examine for damaged or broken strands

- Twist stranded conductors clockwise to consolidate

- Check that all strands are aligned (no fraying)

- Ensure the conductor is clean and free of oxidation

For solid wire, verify the conductor is straight and unbent. For stranded wire, the twisted bundle should maintain a tight, compact shape.

💡 EXPERT TIP: For fine-stranded wire (Class I or II per UL 1581), consider applying a small amount of electrical joint compound to prevent oxidation in outdoor applications.

Step 4: Insert Wire Fully into Terminal Barrel

Proper insertion is critical for a secure connection:

- Slide the wire through the heat shrink sleeve first

- Push the stripped conductor into the metal barrel

- Insert until the wire insulation touches the barrel entrance

- Verify conductor extends to the barrel’s inspection hole

- Check that no bare wire is visible outside the barrel

The terminal should capture both the conductor and approximately 1-2mm of wire insulation for maximum strain relief.

Visual Inspection Points:

- ✓ Conductor visible through inspection hole

- ✓ Wire insulation butts against barrel entrance

- ✓ No conductor strands sticking out

- ✓ Heat shrink sleeve positioned away from crimp area

Step 5: Position and Crimp with Proper Tool Placement

This is the most critical step for connection quality:

- Select the correct die: Match the color-coding (red die for red terminals, etc.)

- Center the barrel: Position the barrel in the middle of the die cavity

- Orient correctly: Ensure the terminal seam faces sideways (not up/down)

- Apply steady pressure: Squeeze the crimper handles completely until ratchet releases

- Inspect the crimp: Look for proper barrel deformation

Proper Crimp Characteristics:

- Barrel forms a “B” or hexagonal shape (depending on die type)

- No cracks or splits in the barrel wall

- Uniform compression across the barrel length

- Slight dimpling where die edges contact the barrel

⚠️ SAFETY WARNING: An under-crimped terminal will pull out under tension. An over-crimped terminal can sever conductor strands. Always crimp until the ratcheting tool releases automatically – never force it open early or squeeze it shut further.

💡 EXPERT TIP: For critical connections, perform a pull test immediately after crimping. The terminal should withstand at least 20 pounds (9kg) of pull force without slipping for 14 AWG wire.

Step 6: Apply Heat to Activate the Seal

Heat shrink activation requires controlled, even heating:

- Position the heat shrink: Slide the sleeve over the crimp barrel and wire junction

- Set heat gun temperature: Use medium heat (300-400°F / 150-200°C)

- Apply heat evenly: Start from the center and work toward the ends

- Watch for indicators:

- Sleeve begins to shrink and conform to the barrel

- Transparent sleeve becomes clear (removes milky appearance)

- Hot melt adhesive melts and flows (visible at sleeve ends)

- Complete shrinking: Heat until adhesive seeps from both ends (this is normal)

- Cool naturally: Allow 2-3 minutes to cure before handling

Heat Application Techniques:

- Keep heat gun moving constantly (never hold in one spot)

- Maintain 2-3 inch distance from terminal

- Rotate the terminal for 360-degree coverage

- Heat the center section first, then each end

⚠️ SAFETY WARNING: Overheating (above 500°F) can damage the wire insulation underneath the sleeve. If you see smoke or smell burning plastic, you’ve applied excessive heat.

💡 EXPERT TIP: For field work without electricity, a butane mini torch works perfectly. Use the outer cone of the flame (not the blue inner cone) and keep it moving rapidly around the terminal.

Step 7: Final Inspection and Testing

A professional installation requires quality verification:

Visual Inspection Checklist:

- ✓ Heat shrink fully conformed to barrel and wire

- ✓ Adhesive visible at both ends of sleeve

- ✓ No air bubbles or gaps under sleeve

- ✓ Wire insulation captured under heat shrink

- ✓ Terminal properly oriented for connection

Electrical Testing:

- Measure resistance across the connection (should be <0.1Ω for most applications)

- Verify continuity through the circuit

- Check for proper voltage at the terminal under load

Mechanical Testing:

- Apply firm pull force to wire (it should not slip)

- Gently flex the connection point (should feel solid)

- Inspect for any wire movement at the barrel

💡 EXPERT TIP: For mission-critical applications (medical, aerospace, safety systems), document each connection with a photo showing proper adhesive seal and include the date, installer initials, and batch number from the terminal package.

Common Crimping Mistakes and How to Avoid Them

The 5 Most Frequent Errors

1. Using the Wrong Terminal Size

Problem: Wire too small for terminal = loose, high-resistance connection; Wire too large = incomplete crimp

Solution: Always match the terminal color code to your wire gauge. When in doubt, verify with a wire gauge tool.

2. Improper Strip Length

Problem: Too short = insulation in barrel creates weak point; Too long = exposed conductor compromises water seal

Solution: Strip length should equal barrel length. Use the terminal itself as a stripping gauge by holding it against the wire.

3. Incomplete Crimping

Problem: Opening the ratcheting crimper before full compression = reduced contact pressure

Solution: Always squeeze until the crimper releases automatically. A proper crimp requires 1,000-2,000 pounds of force.

4. Insufficient Heating

Problem: Heat shrink doesn’t fully shrink = no waterproof seal, adhesive doesn’t flow

Solution: Heat until you see adhesive at both ends of the sleeve. This confirms complete activation.

5. Crimping the Heat Shrink Sleeve

Problem: Positioning the sleeve over the barrel during crimping damages the sleeve

Solution: Always slide the heat shrink away from the crimp area before crimping. Position it afterward before heating.

Troubleshooting Guide for Failed Connections

Here is a table that shows common problems and solutions:

| Symptom | Probable Cause | Solution | Prevention |

|---|---|---|---|

| Wire pulls out of terminal | Under-crimped barrel | Re-crimp with full tool closure or replace | Use ratcheting crimper, crimp until auto-release |

| High resistance reading | Oxidized conductor or poor barrel contact | Clean wire, re-crimp with proper technique | Use contact enhancer on stranded wire |

| Heat shrink won’t seal | Insufficient heat or wrong sleeve type | Apply more heat until adhesive flows | Use proper heat gun temperature (350°F+) |

| Corrosion inside terminal | Moisture entered incomplete seal | Replace terminal, ensure adhesive seals both ends | Verify adhesive flow during heating |

| Terminal melted during heating | Excessive heat application | Replace terminal, use lower temperature | Keep heat gun moving, maintain 2-3″ distance |

| Voltage drop under load | Partial crimp or strand damage | Check for nicked strands, re-terminate | Inspect wire after stripping, don’t over-strip |

| Connection failed vibration | Wrong terminal type or no adhesive seal | Use heat shrink terminals, not standard crimps | Always specify heat shrink for vibration applications |

💡 EXPERT TIP: If you’re experiencing recurring connection failures, the problem is usually tool-related. Worn crimping dies don’t compress evenly. Replace dies annually in high-use environments.

Selecting the Right Heat Shrink Terminals for Your Application

Terminal Type Comparison

Here is a table that shows different heat shrink terminal styles:

| Terminal Type | Applications | Advantages | Wire Range | Typical Cost |

|---|---|---|---|---|

| Ring Terminal | Grounding, battery connections, motor terminals | Secure attachment, can’t disconnect accidentally | 22-4/0 AWG | $0.30-$1.50 |

| Spade Terminal | Quick-disconnect applications, automotive | Easy removal, fits standard spade receptacles | 22-10 AWG | $0.25-$0.60 |

| Butt Splice | Wire-to-wire connections, harness repairs | Connects two wires, color-coded for size | 22-10 AWG | $0.40-$0.80 |

| Disconnect Terminal | Blade fuses, relay sockets, modular connections | Fits 0.25″ tabs, allows quick replacement | 22-10 AWG | $0.35-$0.70 |

| Bullet Connector | Motorcycle wiring, trailer connections | Sealed male/female connection, stackable | 18-10 AWG | $0.50-$1.00 |

Material Selection Guide

Wire Insulation Compatibility:

- PVC insulation: Standard heat shrink terminals (up to 105°C)

- XLPE/cross-linked: Use high-temperature terminals (125°C rated)

- Teflon/PTFE: Requires specialized terminals with controlled shrink ratios

- Silicone rubber: Standard terminals work, but verify temperature rating

Environmental Considerations:

- Marine/saltwater: Tinned copper terminals with dual-wall heat shrink

- Automotive/underhood: Standard terminals rated to 125°C minimum

- Industrial/chemical: Stainless steel terminals with chemical-resistant sleeves

- Outdoor/UV exposure: Black heat shrink (UV-stabilized) or conformal coating

Current Rating Verification:

- 22 AWG: Maximum 7 amps continuous

- 18 AWG: Maximum 10 amps continuous

- 16 AWG: Maximum 13 amps continuous

- 14 AWG: Maximum 17 amps continuous

- 12 AWG: Maximum 23 amps continuous

- 10 AWG: Maximum 33 amps continuous

⚠️ SAFETY WARNING: Always derate ampacity by 20% for bundled wires or elevated ambient temperatures above 86°F (30°C). Undersized terminals create fire hazards.

💡 EXPERT TIP: For professional installations, choose terminals marked with UL or CSA certification stamps. These meet strict quality standards and reduce liability in case of connection failures.

Quality Standards and Code Compliance

Relevant Standards and Certifications

Industry Standards:

- UL 486C: Standard for splicing wire connectors

- SAE J1127: Marine electrical connectors (automotive/marine)

- MIL-DTL-22520: Military specification for crimp quality

- IEC 60352: Solderless connections requirements

- ISO 8092: Road vehicles electrical connections

Required Testing:

- Pull test: Minimum 20 pounds force without slippage (14 AWG)

- Voltage drop: Less than 3% under rated load

- Temperature rise: Less than 30°C above ambient at rated current

- Insulation resistance: Greater than 100 megohms

Professional Installation Requirements:

- Certified installers for marine vessels over 65 feet (ABYC E-11)

- Licensed electricians for building wiring (NEC Article 110)

- OEM-approved methods for automotive safety systems

💡 EXPERT TIP: Document your crimp quality with date, installer, batch number, and pull test results for any connection in safety-critical or warranty-covered equipment.

Advanced Tips for Perfect Crimps Every Time

1. Temperature Management

Pre-warm terminals and wire in cold environments (below 50°F). Cold metal doesn’t crimp as cleanly and heat shrink won’t activate properly below 40°F.

2. Stranding Verification

Class I (solid) vs. Class B (stranded) vs. Class C (fine stranded) wire requires different handling. Fine-stranded wire benefits from twisted ends or ferrules before crimping.

3. Batch Testing

When starting a new box of terminals or using a new crimper, make 3-5 test crimps and pull-test them before production work.

4. Tool Calibration

Professional crimpers require annual calibration. Send tools for calibration or replace dies when you see inconsistent crimp profiles.

5. Color Coding Beyond Size

Some manufacturers use transparent sleeves for inspection, black for UV resistance, and colored for circuit identification. Plan your system accordingly.

6. Wire Preparation Compounds

For outdoor and marine applications, apply a thin coat of dielectric grease or joint compound before crimping to prevent galvanic corrosion.

7. Heat Application Speed

Slower heating (30-45 seconds per terminal) produces better results than fast heating. The adhesive needs time to flow uniformly.

💡 EXPERT TIP: Create a crimping station with all tools within reach: crimper, heat gun, wire strippers, terminals sorted by size, and a pull tester. This setup reduces mistakes and speeds up production by 40%.

Frequently Asked Questions

Can you crimp heat shrink terminals without a heat gun?

Yes, you can use a butane mini torch, cigarette lighter, or even a standard hair dryer in an emergency. A mini torch works best for field work – use the outer flame cone and keep it moving constantly. Hair dryers work but require 3-5 minutes per terminal due to lower temperature. Never use an open flame directly on the terminal as it will melt the sleeve and damage the wire insulation.

How much force should a properly crimped terminal withstand?

A properly crimped 14 AWG terminal should withstand at least 20 pounds (9 kg) of pull force without the wire slipping. For 12 AWG, the minimum is 35 pounds, and for 10 AWG, expect 50+ pounds. The wire should break before pulling out of a correct crimp. Testing can be done by pulling firmly by hand or using a fish scale for verification.

What’s the difference between heat shrink terminals and regular crimp terminals with shrink tubing?

Heat shrink terminals have integrated heat-activated adhesive inside the sleeve that creates a waterproof seal when heated. Standard crimp terminals with separate shrink tubing only provide mechanical protection and insulation but don’t seal against moisture. Heat shrink terminals meet IP67 waterproof ratings while regular crimps with tubing typically only achieve IP44 at best.

Can you reuse a heat shrink terminal if you make a mistake?

No, heat shrink terminals are single-use only. Once crimped and heated, the adhesive bonds permanently and the barrel deforms. Attempting to remove a crimped terminal will damage the wire strands. If you make an error, cut the terminal off and start fresh with a new one. This is why practice crimps on scrap wire are valuable when learning the technique.

Do you need to solder heat shrink terminals for better connections?

No, properly crimped heat shrink terminals should never be soldered. Soldering actually weakens the connection because solder wicks up into the wire strands, creating a rigid point that’s prone to vibration failure. Crimping creates a gas-tight mechanical bond that flexes with the wire. Industry standards like UL 486C and SAE J1127 explicitly prohibit soldering crimped connections.

What temperature should you use for heat shrink terminals?

Use medium heat between 300-400°F (150-200°C) for standard heat shrink terminals. This is hot enough to shrink the sleeve and activate the adhesive without damaging the wire insulation underneath. Most heat guns have adjustable settings – use the middle setting. Overheating above 500°F can damage wire insulation and create brittle connections. The proper indicator is seeing adhesive melt and seep from both ends of the sleeve.

How long do heat shrink terminal connections last?

Properly crimped heat shrink terminals typically last 10-20+ years in automotive applications and 5-10 years in marine environments. The connection itself is permanent, but environmental factors like UV exposure, salt spray, and thermal cycling affect longevity. Terminals with dual-wall construction and marine-grade adhesive last longer than standard types. Failure is usually due to corrosion from incomplete sealing, not crimp degradation.

Can you crimp aluminum wire with standard heat shrink terminals?

No, aluminum wire requires specialized terminals specifically designed for aluminum conductors. Standard copper terminals used on aluminum wire create galvanic corrosion and high-resistance connections. Use terminals marked “AL” or “AL/CU” with an anti-oxidant compound. Aluminum crimping also requires different die profiles and compression ratios. Always follow NEC Article 110.14 requirements when working with aluminum conductors.

What’s the best way to remove a crimped heat shrink terminal?

The safest removal method is cutting the terminal off with wire cutters positioned between the crimp barrel and the wire insulation. Cut perpendicular to the wire, then strip back fresh insulation for a new terminal. For expensive terminals on large gauge wire, you can carefully slice the heat shrink lengthwise with a razor knife and use side cutters to pry open the crimped barrel, but this risks damaging conductor strands.

Do heat shrink terminals work with stranded and solid wire?

Yes, but they’re designed primarily for stranded wire where the crimped barrel grips multiple conductor strands. Solid wire works but provides less surface area for the crimp. For solid wire in vibration environments, consider using terminals with insulation grips or adding ferrules. Always match the terminal’s wire range rating to your conductor type – some terminals specify “stranded only” for this reason.

Professional Installation Checklist

Before starting any crimping project, verify you have:

Tools & Equipment:

- ✓ Ratcheting crimper with correct dies

- ✓ Heat gun (500W minimum, temperature controlled)

- ✓ Adjustable wire strippers

- ✓ Wire gauge measurement tool

- ✓ Pull tester or fish scale

- ✓ Digital multimeter

Materials:

- ✓ Heat shrink terminals in correct sizes

- ✓ Wire appropriate for the application

- ✓ Dielectric grease (for marine/outdoor)

- ✓ Label maker for circuit identification

- ✓ Zip ties or wire loom for support

Quality Control:

- ✓ Make 3 test crimps before production work

- ✓ Pull test every 10th connection

- ✓ Check resistance of critical connections

- ✓ Document installation with photos

- ✓ Record batch numbers for traceability

Safety Compliance:

- ✓ Verify wire gauge matches terminal rating

- ✓ Derate ampacity for bundled wires

- ✓ Confirm terminals meet UL or CSA standards

- ✓ Follow NEC or relevant code requirements

- ✓ Label circuits clearly for future service

⚠️ SAFETY WARNING: Never work on live circuits. Always disconnect power, verify the circuit is dead with a meter, and lockout/tagout according to OSHA requirements before making any electrical connections.

Conclusion: Master Heat Shrink Crimping for Reliable Connections

Crimping heat shrink terminals correctly creates waterproof, vibration-resistant electrical connections that last for decades when done properly. The key success factors are using the right tools, matching terminals to wire gauge, crimping with full compression, and heating until adhesive seals both ends of the sleeve.

Professional electricians and marine technicians rely on heat shrink terminals for mission-critical connections because the sealed design prevents the corrosion and moisture intrusion that causes 80% of electrical failures in harsh environments. By following the seven-step process outlined in this guide and avoiding the common mistakes, you’ll achieve crimp quality that meets or exceeds industry standards.

Your Next Steps:

- Invest in quality tools: A good ratcheting crimper pays for itself in time savings and reduced failures

- Practice on scrap wire: Make 20-30 practice crimps to develop muscle memory

- Document your work: Take photos and record test results for critical installations

- Stay current with codes: Review NEC Article 110 and relevant marine standards (ABYC E-11)

When to Call a Professional:

Contact a licensed electrician or certified marine technician for:

- Building wiring connections requiring code compliance

- High-voltage applications (over 48V)

- Safety-critical systems (medical, aviation, emergency equipment)

- Large gauge wire (6 AWG and larger) requiring hydraulic crimpers

- Installations requiring certification or warranty validation

For professional electrical equipment and certified heat shrink terminals meeting UL and CSA standards, consult with electrical distributors specializing in industrial and marine applications. Quality terminals and proper crimping techniques aren’t just best practices – they’re essential for safety and long-term reliability.

About Professional Electrical Connections:

Properly crimped heat shrink terminals are the gold standard for electrical connections in demanding environments. Whether you’re wiring a boat, building an automotive harness, or installing outdoor lighting, the waterproof seal and mechanical strength of heat shrink technology provides superior protection compared to standard crimp terminals or soldered connections. Master this fundamental skill and you’ll create connections that outlast the equipment they power.