In the world of electrical work, the components you choose are a critical factor in ensuring project safety, long-term reliability, and code compliance. For procurement managers, engineers, and electricians, specifying the correct materials is not just a matter of performance, but of fundamental safety and liability. Among the most basic yet crucial of these components is electrical tape. However, the common confusion between general-purpose vinyl tape and specialist rubber tape can lead to improper applications with significant consequences.

This guide serves as a definitive resource for B2B professionals, clarifying the distinct properties and ideal use cases for both vinyl and rubber electrical tapes. As an expert manufacturer of low-voltage electrical components, TONFUL Electric is committed to empowering our clients with the knowledge to make informed decisions. This article will delve into the material science, advantages, and limitations of each tape, ensuring you can confidently select the right product for every application.

Understanding Electrical Tape: The Basics

At its core, electrical tape is a type of pressure-sensitive tape used to insulate electrical wires and other conductive materials. Its primary purpose is to prevent the electrical current from passing to other wires or components, thereby preventing short circuits and electrical shock. Beyond insulation, it serves several other key functions in professional settings:

- Mechanical Protection: Shielding wires and splices from abrasion, punctures, and physical stress.

- Environmental Sealing: Protecting connections from moisture, dust, and chemicals.

- Bundling and Organization: Grouping wires and cables for a clean, organized installation.

- Identification: Using colored tape to mark or “phase” wires for easy identification of voltage levels and phases, following standardized color codes.

To make an informed purchasing decision, B2B buyers must evaluate electrical tapes based on several key performance metrics:

- Dielectric Strength: The tape’s ability to withstand a certain voltage before breaking down. This is perhaps the most critical property for insulation.

- Adhesion & Elasticity: A quality tape must be elastic enough to be stretched and wrapped tightly, creating a secure, form-fitting seal that remains intact over time. Its adhesive must bond effectively to the wire and to itself without degrading.

- Temperature Rating: Tapes are rated for a specific range of ambient temperatures. Using a tape outside its rated range can cause the adhesive to fail or the material to become brittle.

- Thickness: Measured in mils (one-thousandth of an inch), thickness contributes to both the dielectric strength and the mechanical durability of the tape.

- Material Composition: The base material—most commonly vinyl or rubber—determines the tape’s core characteristics and its suitability for different applications.

While many specialized tapes exist, including mastic and varnished cambric, the vast majority of electrical applications are covered by two primary types: vinyl and rubber.

Deep Dive: Vinyl Electrical Tape

Vinyl electrical tape is the most common and versatile type of electrical tape found in any professional’s toolkit. Its development in the 1940s revolutionized the industry by offering a reliable, stretchy, and durable insulation material.

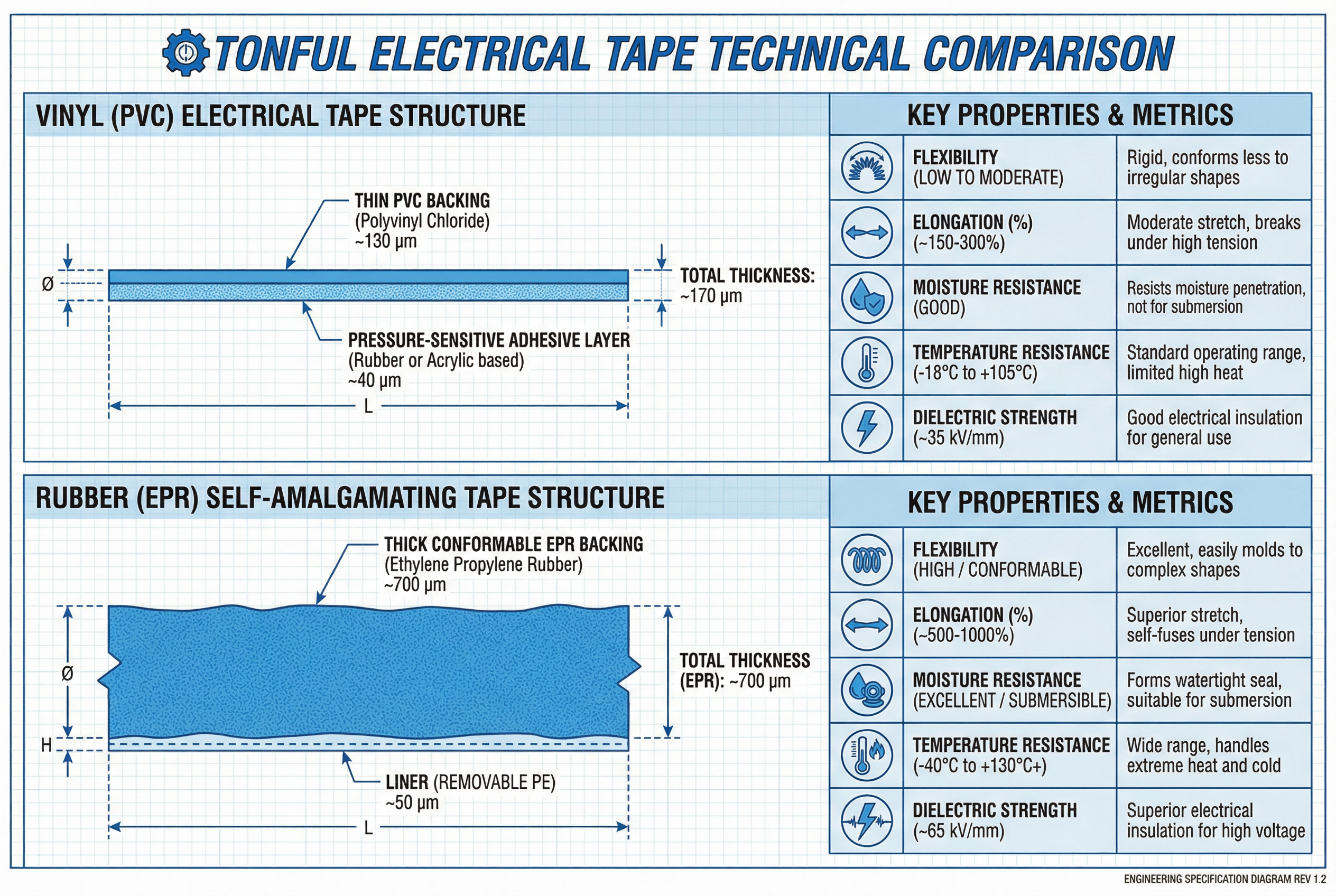

Composition and Properties

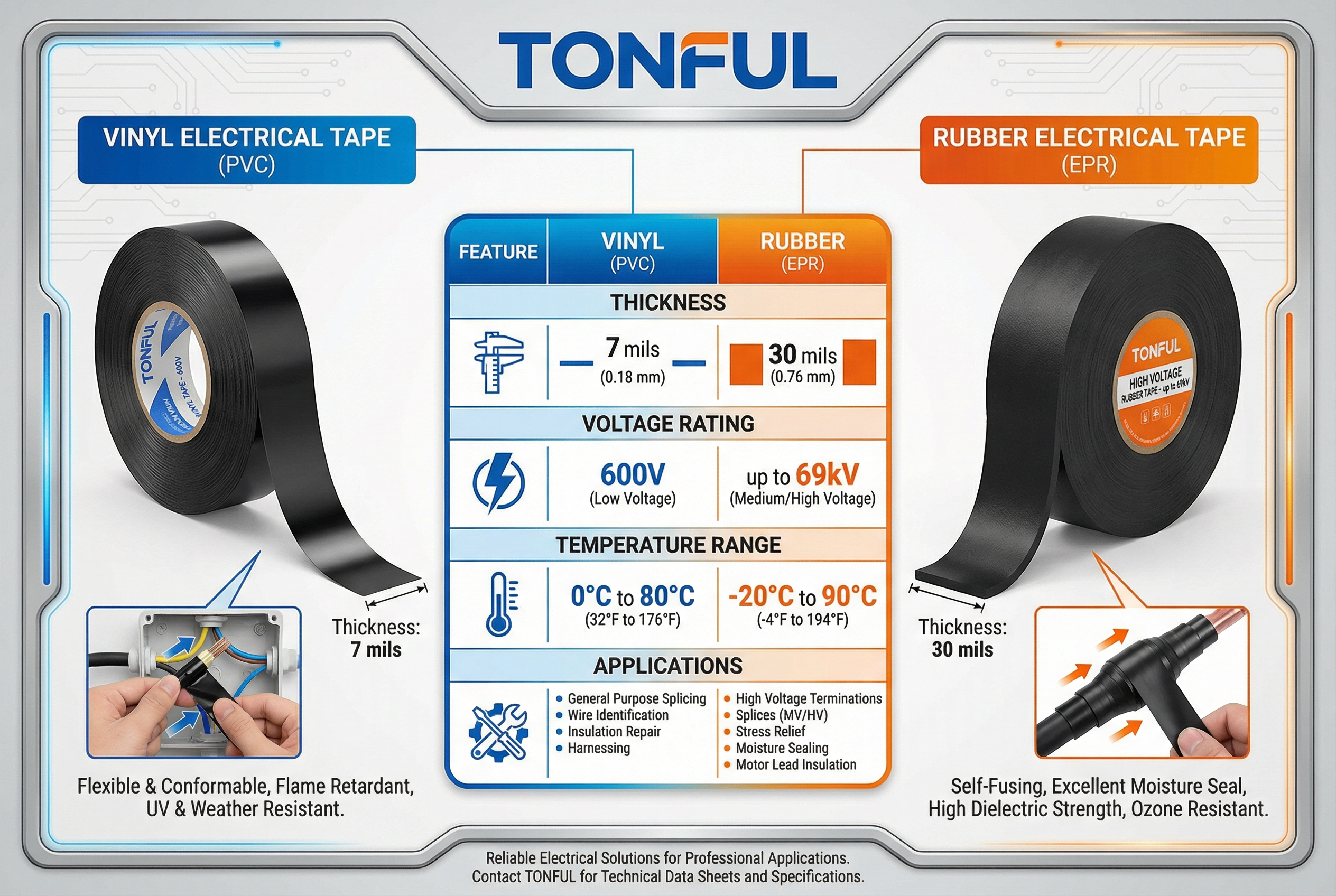

Vinyl tape is made from Polyvinyl Chloride (PVC), which gives it excellent flexibility and resistance to abrasion and moisture. Professional-grade vinyl tapes, such as the industry-standard 3M Super 33+ or 88, are designed to perform in a wide range of conditions, with some rated for temperatures from 0°F to 221°F (-18°C to 105°C). It features a pressure-sensitive rubber-based adhesive that provides a strong bond. Standard thickness is typically around 7 mil.

Pros:

- Cost-Effective: It offers excellent performance for its price, making it the go-to choice for a wide range of tasks.

- Color Availability: Vinyl tape is available in a wide spectrum of colors, making it essential for phasing and identifying circuits.

- Durability: The PVC backing is highly resistant to abrasion, weathering, and chemicals, making it an excellent protective outer jacket.

- UL Listed: Reputable vinyl tapes are UL Listed, ensuring they meet rigorous safety and performance standards.

Cons:

- Limited Voltage Rating: While it is the standard for low-voltage applications (typically rated up to 600V), it is not suitable for primary insulation on medium- or high-voltage cables.

- Less Conformable: Compared to rubber tape, it is less effective at conforming to highly irregular shapes and sharp edges.

- Lower Temperature Limit: It does not handle extreme heat as well as some specialized tapes.

Ideal Applications:

Vinyl tape is the workhorse for most low-voltage electrical work. Its primary uses include:

- Primary insulation for splices on wires rated up to 600V.

- Color-coding and phasing of electrical circuits.

- Bundling and harnessing of wires and cables.

- Providing a durable, protective outer jacket for splices that are first insulated with rubber tape.

- Repairing minor nicks and abrasions in wire insulation.

Deep Dive: Rubber Electrical Tape

Rubber electrical tape is a specialist product designed for high-performance applications where superior insulation and moisture sealing are paramount.

Composition and Properties

Typically made from Ethylene Propylene Rubber (EPR), this tape’s most distinct characteristic is that it is “self-amalgamating” or “self-fusing.” It is a non-adhesive tape; when stretched and wrapped, it chemically bonds to itself, creating a single, seamless, and completely waterproof layer of rubber. This allows it to conform perfectly to any shape, providing a void-free layer of insulation. It is significantly thicker than vinyl tape (often 30 mils or more) and has exceptional elongation, with the ability to stretch up to 1000% of its original length.

Pros:

- Superior Moisture Seal: Its self-fusing nature creates an impenetrable barrier against moisture, making it ideal for outdoor, underground, and submerged applications.

- High-Voltage Insulation: It has a much higher dielectric strength than vinyl, making it the required choice for primary insulation on medium and high-voltage splices (up to 69kV).

- Excellent Conformability: It stretches and conforms effortlessly to irregular shapes like split bolts and bus bars, providing thick, stable insulation.

- Void-Free Application: When applied correctly, it leaves no air gaps, which is critical for preventing corona discharge and insulation failure in high-voltage scenarios.

Cons:

- Requires a Protective Overwrap: Rubber tape has poor resistance to abrasion, UV light, and chemicals. It must be protected by an outer jacket of high-quality vinyl tape.

- Higher Cost: It is a more specialized and expensive product than vinyl tape.

- No Color Options: It is typically only available in black.

Ideal Applications:

Rubber tape is used when performance requirements exceed the capabilities of vinyl tape.

- Primary insulation for splicing and terminating medium- and high-voltage cables.

- Moisture sealing of any electrical connection, regardless of voltage.

- Insulating and padding irregular shapes such as bus bars and split bolts.

- Repairing and sealing high-end cable jackets.

Direct Comparison: Vinyl vs. Rubber at a Glance

For B2B purchasers, understanding the direct trade-offs between these two materials is key to optimizing both cost and performance. Choosing the right tape prevents over-engineering with expensive materials where they aren’t needed and, more importantly, avoids under-engineering that could lead to safety failures.

Composition:

- Vinyl: Polyvinyl Chloride (PVC)

- Rubber: Ethylene Propylene Rubber (EPR)

Primary Function:

- Vinyl: General-purpose insulation, protection, and color-coding (low-voltage).

- Rubber: High-voltage primary insulation and moisture sealing.

Voltage Rating:

- Vinyl: Typically rated up to 600V.

- Rubber: Can be used for applications up to 69,000V (69kV).

Application Method:

- Vinyl: Stretched slightly and wrapped with adhesive side down. Final layer is applied with no tension.

- Rubber: Stretched significantly until it “necks down,” then wrapped in overlapping layers to fuse to itself.

Moisture Seal:

- Vinyl: Good moisture resistance.

- Rubber: Excellent, completely waterproof seal.

UV/Abrasion Resistance:

- Vinyl: Excellent resistance.

- Rubber: Poor resistance; requires a vinyl tape overwrap for protection.

Conformability:

- Vinyl: Good flexibility for general use.

- Rubber: Superior ability to conform to highly irregular shapes.

Selection Guide for Professional Applications

To simplify the decision-making process, TONFUL advises clients to select their tape based on the specific scenario. Here are the most common professional applications and the recommended solution:

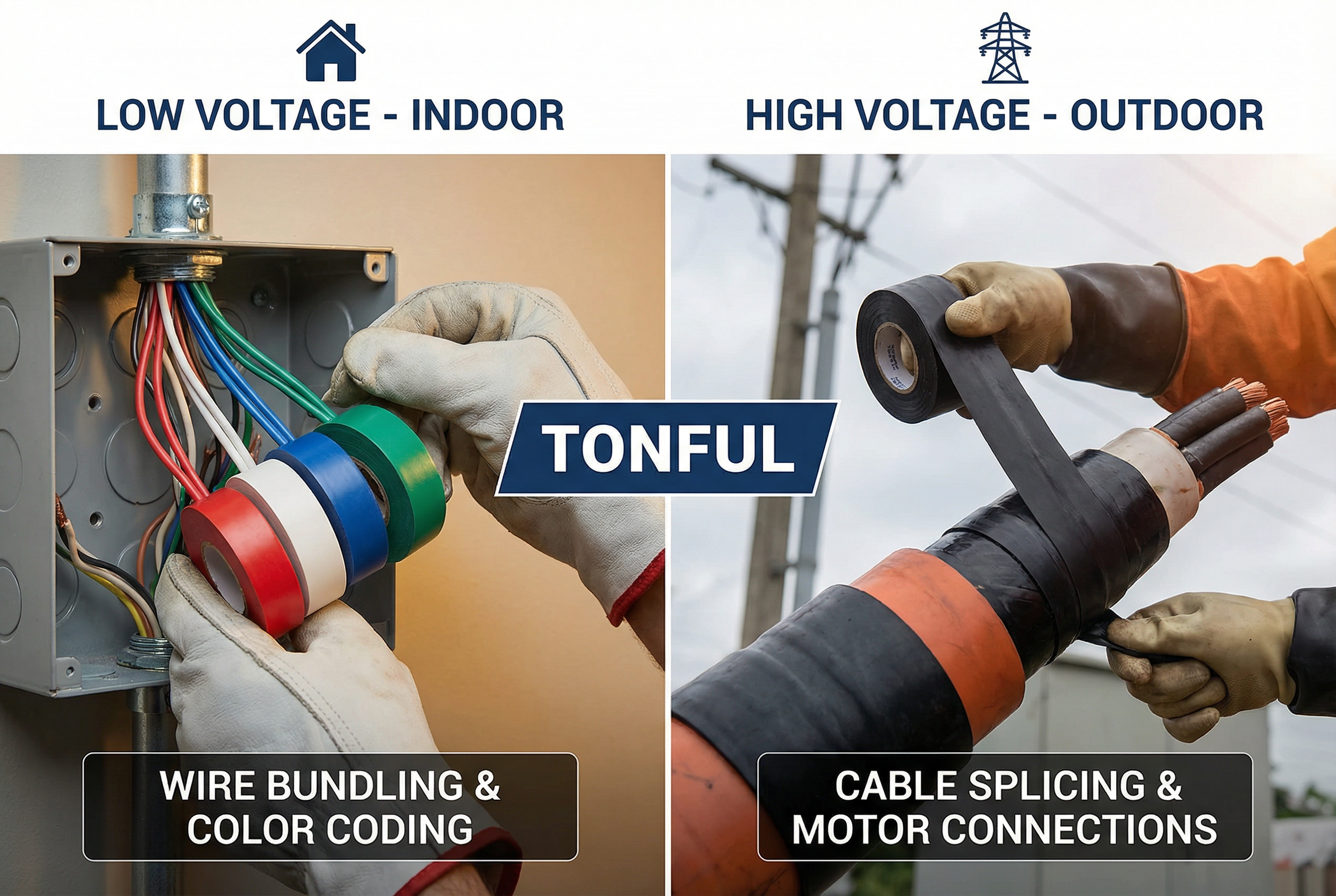

Scenario 1: Indoor, Low-Voltage Wire Splicing (<600V)

- Recommendation: Vinyl Tape. Its 600V rating is sufficient, and its durability provides the necessary mechanical protection. It is the most cost-effective and efficient solution for this common task.

Scenario 2: Outdoor or Underground Connections

- Recommendation: Rubber Tape + Vinyl Tape. First, build up the primary insulation and create a moisture-proof seal using self-fusing rubber tape. Then, overwrap the entire splice with a premium vinyl tape to protect the rubber from UV rays, soil chemicals, and abrasion.

Scenario 3: Medium- or High-Voltage Cable Splicing

- Recommendation: Rubber Tape + Vinyl Tape. This is non-negotiable. Rubber tape is required for its high dielectric strength to serve as the primary insulation. The vinyl tape overwrap is equally required to provide the durable, protective jacket.

Scenario 4: Color-Coding Panels and Motor Leads

- Recommendation: Colored Vinyl Tape. Use standard industry color codes to identify phases and circuits. This is a critical safety practice that only vinyl tape can facilitate.

Scenario 5: Insulating Split Bolts or Bus Bars

- Recommendation: Rubber Tape + Vinyl Tape. The irregular shape of these components requires the superior conformability of rubber tape to pad sharp edges and provide void-free insulation. A vinyl overwrap adds the necessary mechanical protection.

Industry Standards and Certifications

For professional and industrial applications, using unlisted or uncertified tape is an unacceptable risk. B2B buyers must ensure that all electrical tape products carry the proper certifications to guarantee safety, performance, and code compliance. The two most important marks to look for are:

- UL Listed: Underwriters Laboratories (UL) is the leading safety certification organization in the United States. A “UL Listed” mark indicates that the tape has been rigorously tested and meets the requirements of standard ANSI/CAN/UL 510, “Standard for Polymeric Insulating Tapes.” This testing validates the tape’s adhesion, dielectric strength, temperature performance, and flame resistance.

- CSA Approval: The Canadian Standards Association (CSA) provides a parallel certification for products used in Canada, under standard C22.2 No. 197. A tape with CSA approval meets these stringent requirements.

Sourcing tapes that meet these standards is a non-negotiable aspect of professional electrical work. It ensures product reliability and protects against liability. TONFUL Electric exclusively recommends and supplies products that adhere to these critical quality and safety benchmarks.

Conclusion

While they may look similar, vinyl and rubber electrical tapes are engineered for fundamentally different tasks. Vinyl tape is the indispensable, versatile workhorse for the vast majority of low-voltage insulation, protection, and identification needs. Rubber tape is the high-performance specialist, reserved for applications demanding superior high-voltage insulation and an impenetrable moisture seal.

The key to a safe, reliable, and cost-effective electrical installation lies in using both tapes correctly: vinyl for general use, and rubber as the primary insulation for high-voltage and moisture-critical applications, always protected by a vinyl overwrap.

For expert consultation on your low-voltage component needs or to explore our range of certified electrical solutions, contact the TONFUL Electric team today.

Frequently Asked Questions (FAQ)

Q1: Can I use just rubber tape without a vinyl overwrap?

A: It is strongly discouraged. While rubber tape provides excellent electrical insulation and moisture sealing, it has poor resistance to abrasion, UV light, and chemicals. Without a protective vinyl jacket, it can quickly degrade, especially in outdoor or harsh environments, compromising the safety of the splice.

Q2: Is vinyl tape suitable for any primary insulation?

A: Vinyl tape is only suitable for primary insulation in low-voltage applications (typically 600V or less). For medium or high-voltage cables, you must use rubber tape as the primary insulator.

Q3: What does ‘self-amalgamating’ mean and why is it important?

A: ‘Self-amalgamating’ or ‘self-fusing’ means the tape bonds to itself when stretched, creating a single, solid piece of rubber. This is critical for creating a completely waterproof and void-free seal, which is essential for high-voltage stability and preventing moisture intrusion.

Q4: How do temperature ratings affect my choice of tape?

A: You must choose a tape rated for the ambient temperature range of the application. A standard vinyl tape might fail in extremely cold environments (becoming brittle) or high-heat situations (adhesive might ooze). Premium vinyl tapes (like 3M Super 88) are available for wider temperature ranges.

Q5: Why are there so many colors of vinyl tape?

A: The colors are used for phasing and identification of electrical circuits, which is a crucial safety practice. Different colors are used to denote different voltage levels and phases, helping electricians work more safely and efficiently. For example, in the US, black, red, and blue are often used for phases A, B, and C in a 3-phase system.

Q6: Does UL listing really matter for a simple product like tape?

A: Absolutely. A UL listing guarantees that the tape has passed stringent tests for adhesion, flame resistance, dielectric strength, and more. It is a third-party verification that the product will perform as specified, which is critical for ensuring the safety, compliance, and reliability of your electrical installations.