In modern vehicles and industrial equipment, a complex network of electronics governs everything from engine management and safety systems to in-cabin infotainment. These systems represent a significant investment and are critical to operational integrity. Yet, their protection often relies on one of the smallest and most overlooked components in the electrical system: the fuse. The choice of fuse is not a trivial matter; it is a critical decision that impacts reliability, safety, and long-term performance.

For decades, the simple glass-tube fuse was the universal standard. However, as electrical demands grew more sophisticated, a new component emerged and became the undisputed industry benchmark: the automotive blade fuse. This guide provides a comprehensive, professional comparison between the legacy glass fuse and the modern blade fuse. We will explore the technical advantages, practical disadvantages, and specific use cases for each, empowering engineers, fleet managers, and technicians to make informed decisions that ensure maximum electrical system protection.

The Historical Mainstay: The Automotive Glass Fuse

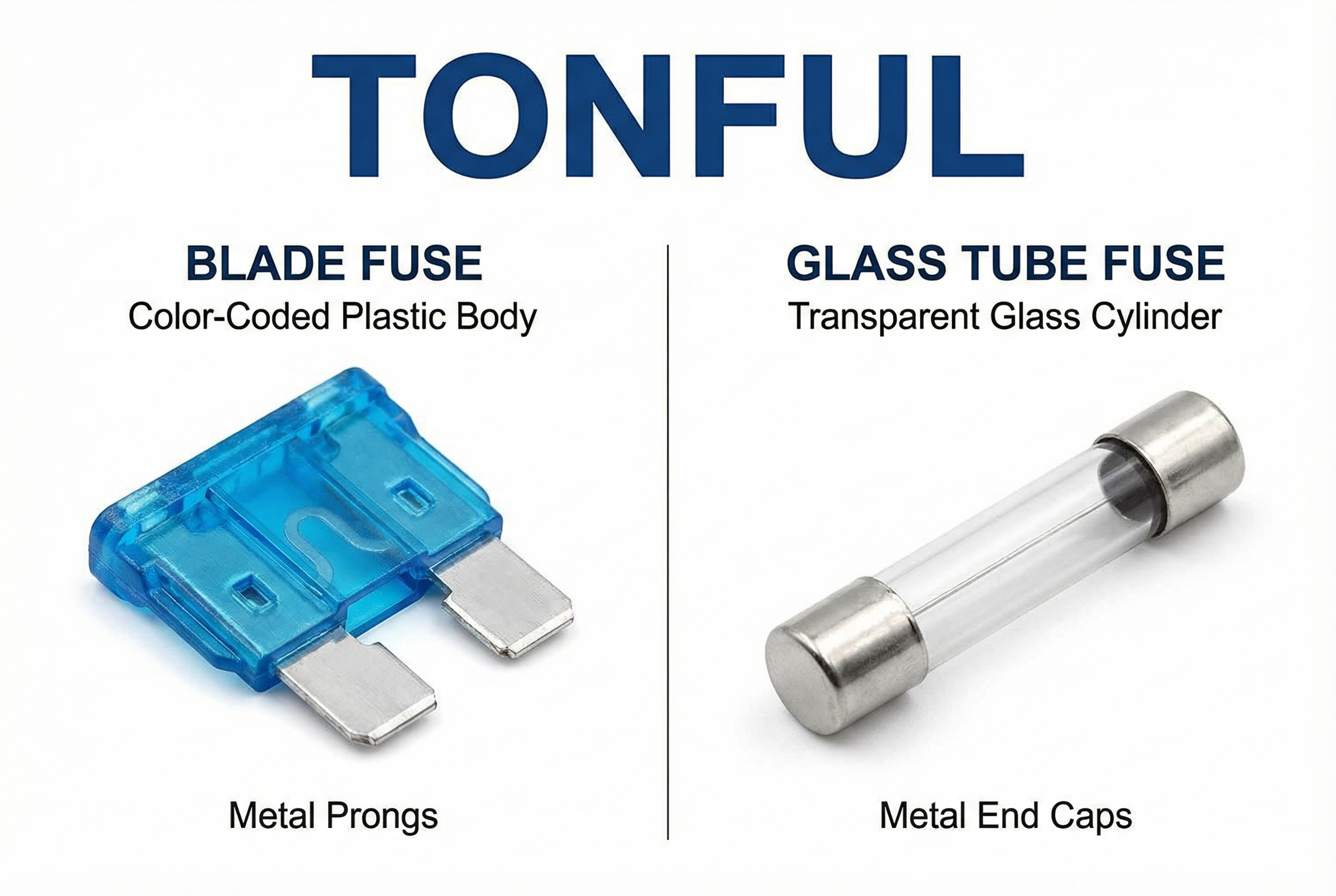

The automotive glass fuse is the classic image that comes to mind when discussing circuit protection. Its design is straightforward: a transparent glass or ceramic tube housing a thin, calibrated metal wire (the fusible element) connected to two metal end caps. When current exceeds the fuse’s rating, the internal wire melts and breaks the circuit, preventing damage to downstream components.

Before the widespread adoption of the blade fuse in the 1980s, glass fuses were the dominant technology in the automotive industry. Various sizes became standard, such as the 1/4″ x 1-1/4″ AGC fuses and the smaller SFE types, which were designed with varying lengths to prevent the accidental installation of an incorrectly rated fuse. For much of the 20th century, this design was sufficient for the relatively simple electrical systems of the time.

However, the inherent characteristics of the glass fuse present significant drawbacks in modern B2B applications.

Pros of Glass Fuses:

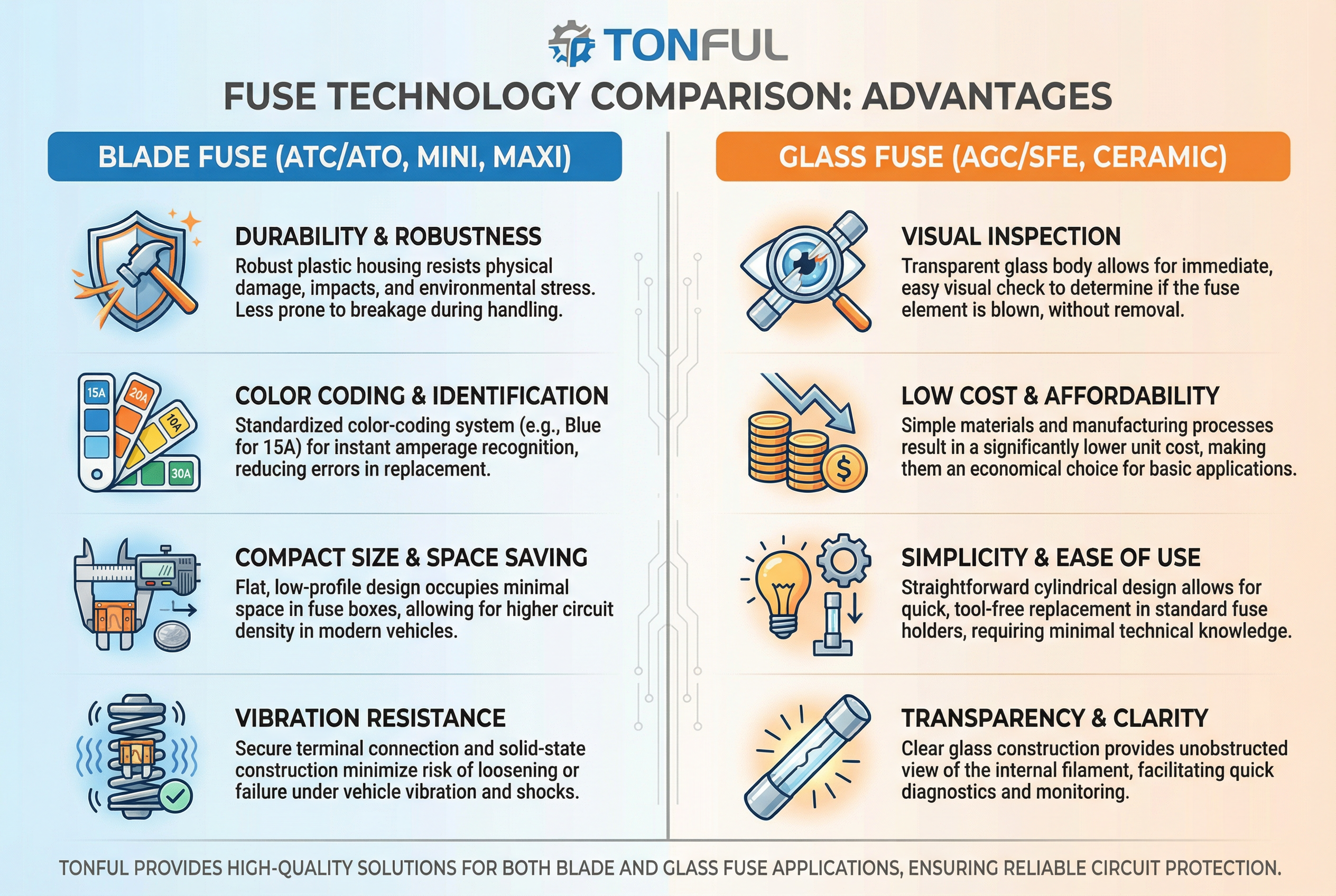

- Visual Inspectability: The primary advantage of a transparent glass fuse is the ease of visual inspection. A quick look can usually confirm if the fusible element is intact or has blown.

- Simplicity: The design is elementary and universally understood.

Cons of Glass Fuses:

- Fragility: The glass body is susceptible to breaking from impact or mishandling, making it less suitable for high-vibration environments.

- Poor Vibration Resistance: The rigid structure and simple wire connection are prone to failure under constant, heavy vibration—a common condition in commercial vehicles and industrial machinery.

- Oxidation and Poor Contact: The metal end caps are held in place by spring clips, which can weaken over time. This can lead to poor electrical contact and oxidation, creating resistance that generates heat and can cause the fuse holder to melt.

- Lower Precision: The manufacturing process for the fusible wire in glass fuses is generally less precise than that of modern blade fuses, leading to wider tolerances in their amperage rating.

Primary Use Case:

Today, the use of glass fuses is almost exclusively limited to the restoration of classic vehicles and the maintenance of older equipment where originality is a key concern. For any new design or modern application, they are considered obsolete technology.

The Modern Standard: The Automotive Blade Fuse

Developed by Littelfuse in 1976 and gaining widespread popularity in the 1980s, the automotive blade fuse was a revolutionary step forward in circuit protection. Its design directly addresses the shortcomings of the glass fuse. A blade fuse consists of a flat, color-coded plastic body that houses the fusible element, terminating in two blade-style prongs that plug directly into a fuse block.

This design provides a secure, push-in connection that dramatically improves reliability and space efficiency. The shift to the blade fuse was driven by the rapid computerization of vehicles; as more electronic control units (ECUs), sensors, and accessories were added, vehicles required more circuits and, therefore, more fuses. The compact and robust nature of the blade fuse was the ideal solution.

Pros of Blade Fuses:

- Superior Durability and Vibration Resistance: The robust plastic housing and secure terminal design make blade fuses highly resistant to both physical shock and the constant vibration of vehicle operation.

- High Precision and Safety: Blade fuses are manufactured to tight tolerances, ensuring they blow at their exact rated amperage. This precision is critical for protecting sensitive modern electronics.

- Space Efficiency: The compact design and integrated fuse blocks allow for a high density of fuses in a small area, a crucial advantage in modern, space-constrained vehicles.

- Standardization and Ease of Use: The universal color-coding system, standardized by bodies like the SAE, allows technicians to immediately identify the amperage rating of a fuse without needing to read fine print.

- Secure Connection: The blade terminals provide a large surface area for electrical contact and are held securely in the fuse block, preventing issues related to oxidation or loose connections that plague glass fuse holders.

Cons of Blade Fuses:

- Inspection Difficulty: While some blade fuses feature a clear top, determining if the element is blown can be more difficult than with a glass fuse, often requiring better lighting or removal for continuity testing.

- Size Variation: The proliferation of multiple blade fuse sizes (Maxi, Standard, Mini, Micro) can cause confusion if a technician is not familiar with the different types.

Deep Dive: Understanding Blade Fuse Types

While the term “blade fuse” is used universally, it encompasses several distinct sizes, each designed for different space and amperage requirements. Choosing the correct form factor is as important as choosing the right amperage.

Here are the most common types of blade fuses found in automotive and commercial applications:

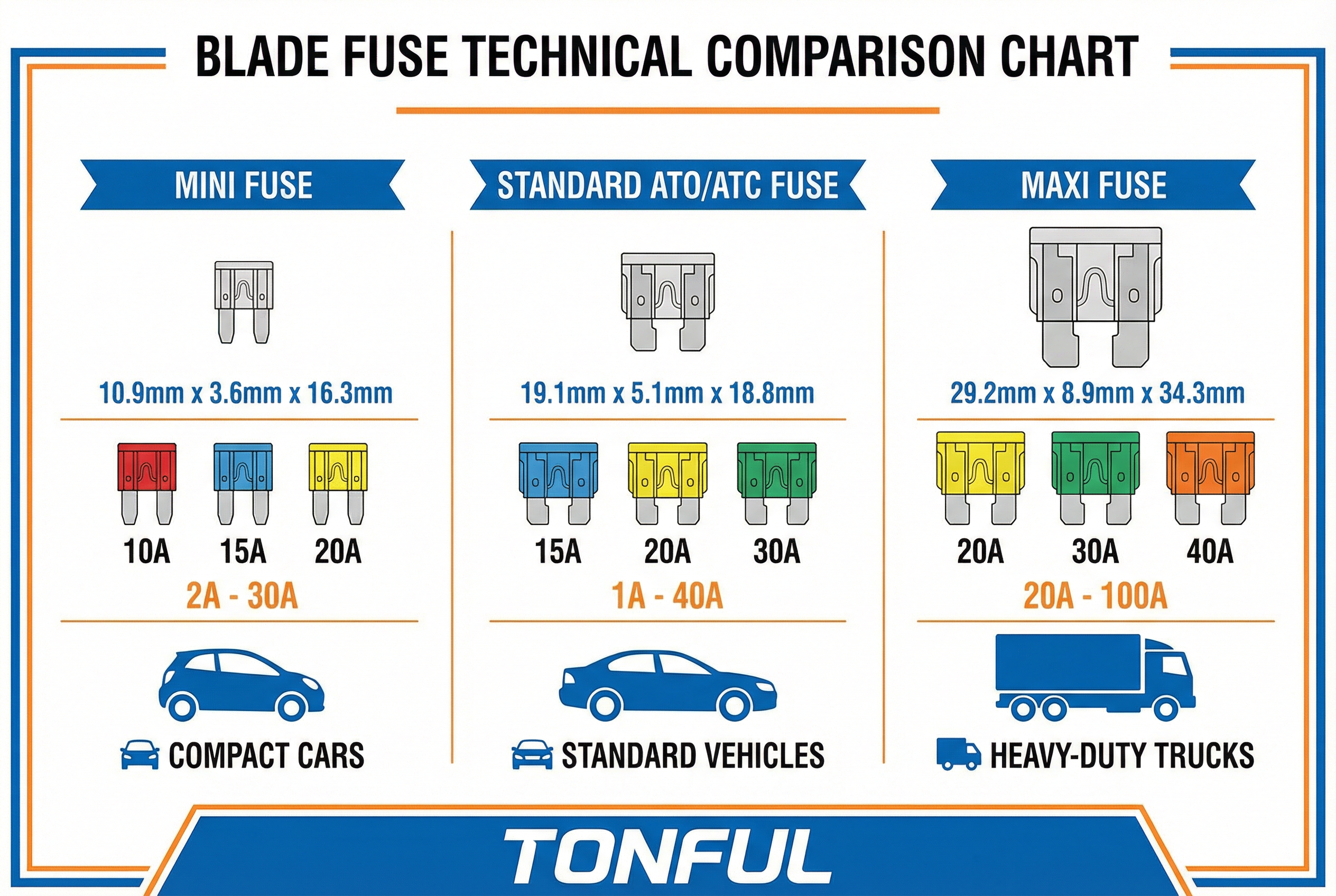

- Maxi Blade Fuses (APX): The largest of the blade fuses, these are designed for high-current applications, typically protecting main vehicle circuits like alternators, starters, and main power feeds. Their amperage ratings commonly range from 20A to 120A.

- Standard Blade Fuses (ATO/ATC): For years, this was the most common blade fuse. “ATO” stands for Automotive Technology Organization, while “ATC” signifies a closed-element version, offering more environmental and moisture protection. They are used for a huge range of applications, from headlights to radio circuits, with ratings typically from 1A to 40A.

- Mini Blade Fuses (APM/ATM): As vehicle interiors became more packed with electronics, the need for a more compact fuse emerged. The Mini blade fuse offers the same performance as the Standard fuse but in a much smaller package, allowing for more fuses in a smaller fuse block. Their amperage ratings are typically between 2A and 30A.

- Low-Profile Mini Fuses: A variation on the Mini fuse, these are even shorter, offering maximum space savings.

- Micro Fuses (Micro2 & Micro3): These are the newest generation of blade fuses, designed for the extremely dense electronic environments of the latest vehicles. The Micro2 is a two-terminal fuse, while the Micro3 is a three-terminal fuse that can protect two different circuits in the space of a single fuse, offering even greater space efficiency.

Understanding these different types is crucial for proper maintenance and service, as they are not interchangeable.

Head-to-Head Comparison: Blade Fuse vs. Glass Fuse

When directly compared, the technical superiority of the blade fuse for any modern application becomes clear. The choice for engineers and fleet managers is not which is better, but rather confirming that all systems are utilizing this more advanced and reliable technology.

| Feature | Glass Fuse | Automotive Blade Fuse | Winner |

|---|---|---|---|

| Durability | Poor (fragile glass construction) | Excellent (robust, enclosed plastic body) | Blade Fuse |

| Vibration Resistance | Poor (prone to connection loss and fatigue) | Excellent (secure push-in terminals) | Blade Fuse |

| Precision & Accuracy | Fair to Good (wider manufacturing tolerances) | Excellent (manufactured to precise standards like ISO 8820) | Blade Fuse |

| Safety | Fair (exposed clips, risk of holder meltdown) | Excellent (fully enclosed element, secure housing) | Blade Fuse |

| Size & Space Efficiency | Poor (bulky for the number of circuits protected) | Excellent (high-density fuse blocks) | Blade Fuse |

| Standardization | Fair (multiple lengths like SFE, AGC, etc.) | Excellent (universal, amperage-based color-coding) | Blade Fuse |

| Ease of Inspection | Excellent (transparent body) | Fair to Good (requires removal or good lighting) | Glass Fuse |

| Availability (Modern) | Poor (specialty item for classic cars) | Excellent (ubiquitous in all modern vehicles) | Blade Fuse |

While the glass fuse wins on the single point of visual inspection, this minor convenience is overwhelmingly outweighed by the blade fuse’s advantages in every other category, particularly those critical to safety and reliability.

Professional Selection Guidelines

Selecting the correct fuse is a matter of safety and system integrity. Using the wrong fuse can lead to recurring electrical issues or, in a worst-case scenario, catastrophic failure and fire. Follow these professional guidelines to ensure proper circuit protection.

Step 1: Identify the Fuse Type and Size

First, determine the correct fuse form factor required by the equipment. Is it a glass fuse for a legacy system or, more likely, a blade fuse? If it is a blade-style, identify the specific size: Maxi, Standard (ATO/ATC), Mini (APM/ATM), or Micro. Using a Mini fuse in a slot designed for a Standard fuse, even if the amperage is correct, will result in a loose connection that is guaranteed to fail.

Step 2: Determine the Correct Amperage Rating

This is the most critical step. The amperage rating is the amount of electrical current the fuse can handle before it blows. Never replace a fuse with one of a higher amperage rating. The original rating was chosen by the engineer to protect the specific wiring and components of that circuit. Installing a higher-rated fuse will allow excessive current to flow, potentially melting wires and causing a fire before the fuse ever blows. The correct amperage can be found in:

- The vehicle or equipment owner’s manual.

- A diagram on the fuse box cover.

- Service documentation for the equipment.

Step 3: Verify with the Blade Fuse Color Code

For blade fuses, the color of the plastic housing provides an instant, reliable confirmation of the amperage rating. This system is standardized by SAE International standard J1284 and is a critical tool for technicians.

Common Blade Fuse Color Codes:

- Black: 1A

- Grey: 2A

- Violet: 3A

- Pink: 4A

- Tan: 5A

- Brown: 7.5A

- Red: 10A

- Blue: 15A

- Yellow: 20A

- Clear/White: 25A

- Green: 30A

- Orange: 40A (Standard Blade)

Always use the color code as a secondary check to confirm the amperage rating printed on the top of the fuse.

Step 4: Insist on Quality and Standards Compliance

Not all blade fuses are created equal. For professional and B2B applications, it is imperative to use high-quality fuses that conform to international standards like ISO 8820. Low-quality, uncertified fuses often use plastics with low melting points that can deform in high-heat environments, or use poorly calibrated fusible elements that do not blow at the specified current. This renders them unreliable and dangerous. A quality blade fuse will have a clearly marked amperage rating, manufacturer identification, and will be made from high-temperature resistant polycarbonate.

Frequently Asked Questions (FAQ)

1. Can I replace a glass fuse with a blade fuse?

It is possible but requires replacing the entire fuse holder. You cannot simply plug a blade fuse into a glass fuse holder. For any modern application where reliability is important, upgrading the fuse block from glass to a blade-style system is a recommended long-term solution.

2. What happens if I use a fuse with a higher amperage rating?

This is extremely dangerous. The fuse exists to be the weakest link in the circuit. If you install a 30A fuse in a circuit designed for 10A, you are allowing three times the intended current to flow. This will not protect the circuit’s wiring, which will likely overheat, melt its insulation, and cause a short circuit or fire long before the fuse blows.

3. Why is it important to use fuses that meet SAE/ISO standards?

SAE and ISO standards govern the performance, dimensions, and materials of automotive fuses. A fuse that meets these standards is guaranteed to perform reliably and safely. It will blow at the correct current, withstand vibration, and tolerate the temperature extremes found in automotive and industrial environments. Using non-compliant fuses is a significant liability and risks the very equipment they are meant to protect.

Conclusion: The Clear Choice for Modern Electrical Protection

The evolution from the glass fuse to the modern blade fuse marks a significant advancement in electrical system safety and reliability. While glass fuses served their purpose in a simpler era, their inherent weaknesses in durability, precision, and safety make them entirely unsuitable for the demands of today’s technology.

For any B2B application—from commercial fleet vehicles and heavy machinery to sophisticated industrial controls—the automotive blade fuse is the only acceptable standard. Its robust design, precise performance, and universal standardization provide the level of protection that complex electronic systems demand. However, the protection is only as reliable as the component itself. Ensuring every blade fuse is of high quality and compliant with ISO 8820 standards is not just a best practice; it is a fundamental requirement of professional electrical work.

For B2B applications demanding unwavering reliability and compliance, choosing a trusted manufacturer is key. Explore Tonful Electric’s range of standards-compliant automotive blade fuses to ensure maximum protection and performance for your systems.