Quick Answer: The top insulated terminal manufacturers combine advanced polymer insulation technology with precision-engineered conductors to deliver safe, reliable electrical connections. Leading manufacturers like Tonful Electric, TE Connectivity, and Phoenix Contact offer certified products meeting UL, CSA, and IEC safety standards for industrial, automotive, and marine applications.

Are you searching for reliable insulated terminal manufacturers to ensure safe electrical connections in your critical systems? This comprehensive guide explores the leading insulated terminal manufacturers of 2025, comparing their technologies, certifications, and specializations to help you make informed decisions about electrical safety and connectivity solutions.

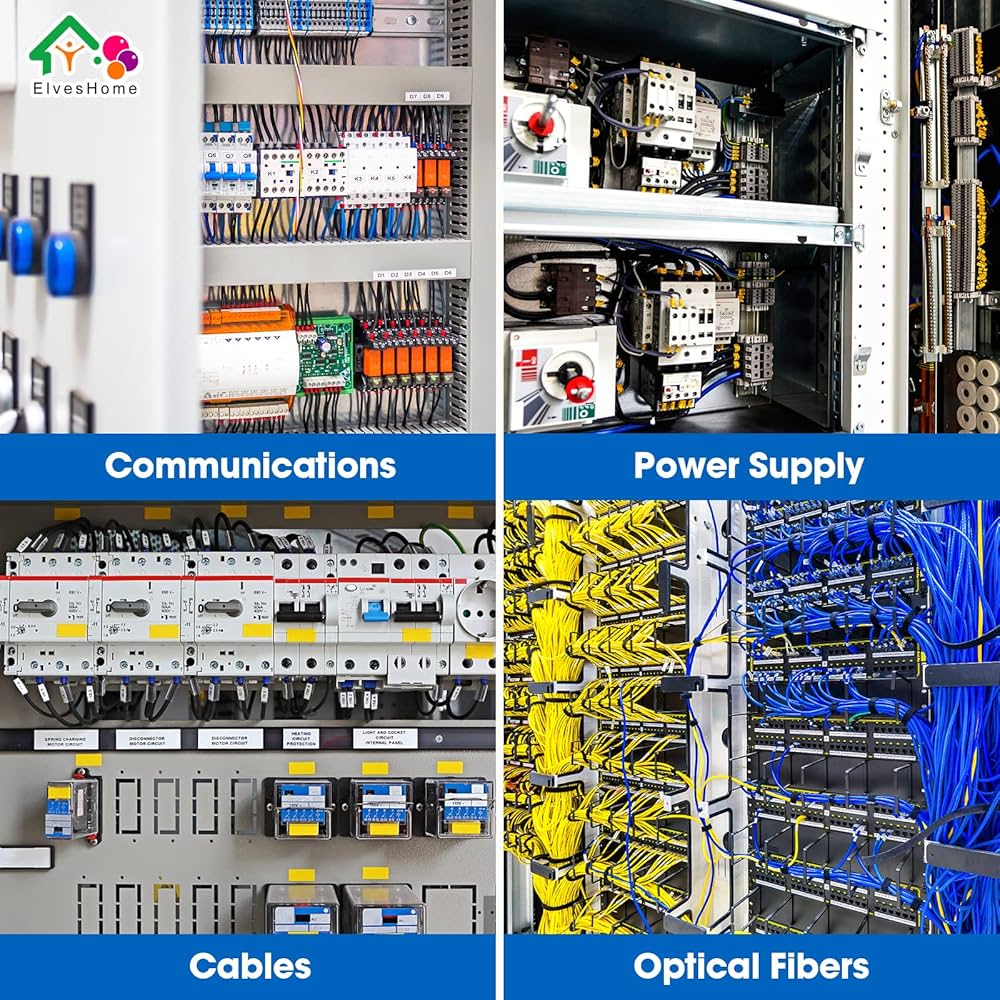

WHAT ARE INSULATED TERMINALS AND WHY ARE THEY ESSENTIAL?

Insulated terminals are electrical connectors featuring protective polymer or vinyl coverings that prevent accidental contact, short circuits, and electrical hazards. Unlike bare terminals, insulated versions provide crucial safety barriers while maintaining secure electrical connections.

Key Safety Benefits of Insulated Terminals:

- Electrical shock protection – Insulation prevents accidental contact with live conductors

- Short circuit prevention – Protective barriers eliminate conductor-to-conductor contact

- Environmental protection – Sealed designs resist moisture, dust, and corrosive substances

- Visual identification – Color-coded insulation enables quick circuit identification

- Code compliance – Meets NEC, CSA, and international electrical safety standards

Expert Safety Tip: According to OSHA regulations, insulated terminals are mandatory in applications where conductors operate above 50 volts or in wet/hazardous locations. Always verify insulation ratings match your voltage requirements.

INSULATED TERMINAL TYPES: COMPREHENSIVE TECHNICAL GUIDE

| Terminal Type | Insulation Material | Voltage Rating | Temperature Range | Primary Applications |

|---|---|---|---|---|

| Ring Terminals | PVC/Nylon | 600V-1000V | -40°C to +105°C | Motor connections, grounding |

| Spade Terminals | Vinyl/PVC | 300V-600V | -40°C to +90°C | Quick-disconnect applications |

| Bullet Terminals | PVC/Nylon | 250V-600V | -40°C to +105°C | Automotive, marine wiring |

| Quick Disconnects | Vinyl/Nylon | 250V-600V | -40°C to +105°C | Appliances, control panels |

| Wire Nuts | Thermoplastic | 600V-1000V | -40°C to +150°C | Building wire connections |

| Butt Connectors | Heat Shrink/PVC | 600V-1000V | -55°C to +125°C | Splice applications |

GLOBAL INSULATED TERMINAL MARKET ANALYSIS: 2025 TRENDS

The global insulated terminal market has reached $3.2 billion in 2024, with projected growth at 5.3% CAGR through 2030. This expansion is driven by:

Market Growth Drivers:

- Renewable energy installations requiring weather-resistant connections

- Electric vehicle adoption demanding high-voltage insulated terminals

- Industrial automation expansion increasing safety requirements

- Smart grid infrastructure requiring reliable insulated connections

- Stricter electrical codes mandating insulation in more applications

Regional Market Distribution:

| Region | Market Share | Growth Rate | Key Trends |

|---|---|---|---|

| North America | 35% | 4.8% | Focus on UL/CSA compliance |

| Europe | 28% | 4.2% | Emphasis on environmental standards |

| Asia-Pacific | 30% | 7.1% | Rapid industrialization driving demand |

| Rest of World | 7% | 5.9% | Infrastructure development increasing adoption |

TOP 10 INSULATED TERMINAL MANUFACTURERS OF 2025

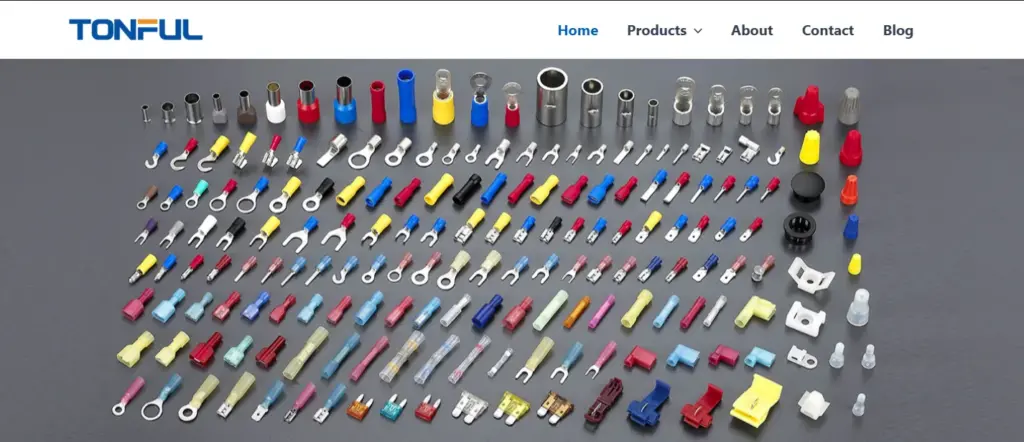

1. TONFUL ELECTRIC: PRECISION-ENGINEERED INSULATED TERMINALS

Website: https://tonful.com

Tonful Electric leads the insulated terminal manufacturing industry through innovative design and rigorous quality control. Established as a premier low-voltage electrical manufacturer, Tonful Electric specializes in producing high-performance insulated terminals that exceed international safety standards.

Tonful Electric’s Advanced Features:

- Triple-layer insulation technology providing superior electrical protection

- High-grade copper conductors ensuring optimal current-carrying capacity

- Color-coded identification system simplifying installation and maintenance

- Wide temperature range (-40°C to +105°C) for diverse applications

- UL, CSA, and CE certifications meeting global safety requirements

Product Specializations:

- Ring terminals (12-4 AWG) with seamless insulation

- Spade terminals featuring reinforced stress relief

- Quick disconnect terminals for rapid maintenance

- Bullet terminals designed for automotive applications

- Custom terminals for specialized industrial requirements

Why Choose Tonful Electric:

Tonful Electric’s manufacturing facility employs precision crimping technology and automated quality testing, ensuring every insulated terminal meets the highest performance standards. Their technical support team provides application-specific recommendations and custom solutions for unique connectivity challenges.

Key Product: Tonful’s TF-RT Series ring terminals feature advanced polymer insulation with integrated strain relief, delivering exceptional durability in high-vibration environments.

2. TE CONNECTIVITY: GLOBAL LEADER IN INSULATED CONNECTION SOLUTIONS

Website: https://www.te.com

TE Connectivity stands as a global powerhouse in connectivity solutions, with their insulated terminal portfolio spanning automotive, industrial, and aerospace applications. Their comprehensive range addresses virtually every insulated connection requirement.

TE Connectivity Advantages:

- Extensive product catalog covering all terminal types and sizes

- Advanced materials science developing superior insulation compounds

- Global manufacturing footprint ensuring consistent worldwide availability

- Application-specific designs optimized for harsh environments

- Comprehensive testing protocols validating long-term reliability

Specialized Applications:

TE Connectivity excels in high-reliability applications requiring exceptional performance under extreme conditions, particularly in automotive and aerospace systems.

Key Product: TE’s FASTON series quick disconnect terminals provide reliable connections with superior insulation integrity in high-cycle applications.

3. PHOENIX CONTACT: GERMAN-ENGINEERED PRECISION TERMINALS

Website: https://www.phoenixcontact.com

Phoenix Contact brings German engineering excellence to insulated terminal manufacturing, focusing on industrial automation and control applications where reliability is paramount.

Phoenix Contact Features:

- Precision manufacturing ensuring consistent connection quality

- Modular terminal systems enabling systematic wiring organization

- Advanced marking systems facilitating maintenance and troubleshooting

- High-temperature insulation suitable for demanding industrial environments

- Comprehensive accessories including end stops and jumpers

Industrial Focus:

Phoenix Contact terminals excel in industrial control panels, process automation, and building management systems requiring long-term reliability.

Key Product: Phoenix Contact’s AI series insulated terminals feature push-in connection technology with color-coded insulation for rapid installation.

4. MOLEX: INNOVATIVE INSULATED TERMINAL SOLUTIONS

Website: https://www.molex.com

Molex has established itself as an innovation leader in the insulated terminal market, developing user-friendly designs that simplify installation while maintaining superior electrical performance.

Molex Innovations:

- Ergonomic wire entry designs reducing installation time and effort

- Space-efficient configurations maximizing panel density

- Enhanced insulation materials providing superior environmental protection

- Mixed-technology solutions accommodating various conductor types

- Custom terminal development for specialized applications

Application Strengths:

Molex terminals are particularly strong in consumer electronics, medical devices, and telecommunications where compact, reliable connections are essential.

Key Product: Molex’s barrier strip terminals feature enhanced insulation with integrated wire guides for error-free installation.

5. 3M: ADVANCED MATERIALS TECHNOLOGY IN INSULATED TERMINALS

Website: https://www.3m.com

3M leverages their advanced materials science expertise to produce insulated terminals with superior environmental resistance and long-term reliability.

3M Material Advantages:

- Proprietary insulation compounds offering exceptional chemical resistance

- Heat-activated sealing systems providing moisture protection

- High-temperature polymers maintaining properties in extreme conditions

- Color-stable materials ensuring lasting visual identification

- Flame-retardant formulations meeting stringent safety standards

Specialized Markets:

3M terminals excel in harsh environment applications including marine, chemical processing, and outdoor installations.

Key Product: 3M’s Scotchlok series insulated terminals feature heat-shrink insulation providing permanent environmental sealing.

6. HUA WEI INDUSTRIAL CO., LTD.: PRECISION ASIAN MANUFACTURING

Website: https://www.huaweiindustrial.com

Hua Wei Industrial has established itself as a leading Asian manufacturer of insulated terminals, combining traditional craftsmanship with modern manufacturing technology.

Hua Wei Strengths:

- Cost-effective manufacturing delivering value without compromising quality

- Flexible production capabilities accommodating custom specifications

- Rapid prototyping services for specialized terminal requirements

- Quality certifications meeting international standards

- Regional market expertise understanding Asian application requirements

Market Position:

Hua Wei Industrial serves as a reliable supplier for OEMs requiring high-volume, consistent-quality insulated terminals at competitive prices.

Key Product: Hua Wei’s HW series ring terminals provide reliable connections with durable PVC insulation for general industrial applications.

7. K.S. TERMINALS INC: SPECIALIZED INSULATED CONNECTOR SOLUTIONS

Website: https://www.ksterminals.com

K.S. Terminals focuses on specialized insulated terminal applications, developing solutions for unique connectivity challenges in niche markets.

K.S. Terminals Specializations:

- Custom terminal design for unique application requirements

- Specialized insulation materials for extreme environment applications

- Small-batch production serving specialized market segments

- Technical consultation providing application engineering support

- Rapid delivery for urgent project requirements

Niche Markets:

K.S. Terminals serves specialized industries including renewable energy, industrial equipment, and custom machinery manufacturers.

Key Product: K.S. Terminals’ heavy-duty ring terminals feature reinforced insulation designed for high-vibration industrial equipment.

8. AMERICAN ELECTRICAL, INC: US-MADE INSULATED TERMINALS

Website: https://www.americanelectrical.com

American Electrical specializes in manufacturing insulated terminals for the North American market, focusing on NEC compliance and UL certification requirements.

American Electrical Features:

- NEC-compliant designs ensuring code compliance for US installations

- UL-listed products meeting American safety standards

- Domestic manufacturing providing rapid delivery and support

- Technical documentation supporting electrical code compliance

- Training programs educating installers on proper terminal selection

Market Focus:

American Electrical serves electrical contractors, industrial facilities, and OEMs requiring code-compliant insulated terminals for US installations.

Key Product: American Electrical’s AE series spade terminals feature UL-recognized insulation meeting NEC requirements for general wiring applications.

9. JEESOON TERMINALS CO LTD: ASIAN MANUFACTURING EXCELLENCE

Website: https://www.jeesoon.com.tw/

Jeesoon Terminals represents Asian manufacturing excellence in insulated terminal production, combining quality manufacturing with competitive pricing.

Jeesoon Advantages:

- ISO-certified manufacturing ensuring consistent quality control

- Competitive pricing providing value for high-volume applications

- Flexible production accommodating various order quantities

- Quality assurance implementing comprehensive testing protocols

- Export expertise serving global markets with reliable delivery

Global Reach:

Jeesoon Terminals serves international markets with particular strength in industrial and automotive applications.

Key Product: Jeesoon’s JS series bullet terminals feature durable vinyl insulation designed for automotive and marine applications.

10. ELECDIRECT.COM: COMPREHENSIVE INSULATED TERMINAL DISTRIBUTION

Website: https://www.elecdirect.com

ElecDirect.com serves as both a manufacturer and comprehensive distributor of insulated terminals, providing one-stop sourcing for electrical contractors and industrial users.

ElecDirect Services:

- Comprehensive inventory covering all insulated terminal types

- Technical support assisting with terminal selection and application

- Custom kitting services preparing project-specific terminal packages

- Educational resources providing installation and safety guidance

- Rapid delivery supporting urgent project requirements

Distribution Strength:

ElecDirect.com excels in serving electrical contractors and maintenance professionals requiring reliable access to diverse insulated terminal products.

Key Product: ElecDirect’s contractor-grade terminal assortments provide comprehensive selection of commonly-used insulated terminals in convenient packaging.

HOW TO CHOOSE THE RIGHT INSULATED TERMINAL MANUFACTURER

CERTIFICATION AND SAFETY COMPLIANCE

Essential Certifications to Verify:

- UL 486A/486B – Underwriters Laboratories wire connector standards

- CSA C22.2 No. 65 – Canadian Standards Association requirements

- IEC 60999 – International Electrotechnical Commission standards

- RoHS compliance – Environmental safety requirements

- REACH compliance – European chemical safety regulations

Expert Safety Warning: Always verify that insulated terminals carry appropriate certifications for your specific application and installation location. Using non-certified terminals in commercial or industrial installations may violate electrical codes and void insurance coverage.

TECHNICAL SPECIFICATION COMPARISON

| Specification | Standard Range | Premium Range | High-Performance Range |

|---|---|---|---|

| Voltage Rating | 300V-600V | 600V-1000V | 1000V+ |

| Current Capacity | 15A-30A | 30A-100A | 100A+ |

| Temperature Range | -20°C to +80°C | -40°C to +105°C | -55°C to +150°C |

| Wire Gauge Range | 22-12 AWG | 18-6 AWG | 16-4/0 AWG |

| Insulation Thickness | 0.5-0.8mm | 0.8-1.2mm | 1.2mm+ |

MATERIAL QUALITY INDICATORS

Premium Insulation Materials:

- Nylon insulation – Superior temperature and chemical resistance

- Cross-linked polyethylene – Enhanced durability and flexibility

- Heat-shrink materials – Permanent environmental sealing

- Flame-retardant compounds – Meeting safety standards

- Color-stable formulations – Maintaining identification integrity

Conductor Quality Factors:

- Oxygen-free copper – Maximum conductivity and corrosion resistance

- Tin plating – Enhanced solderability and corrosion protection

- Seamless construction – Eliminating weak points and failure modes

- Precision crimping – Ensuring optimal mechanical and electrical connection

- Stress relief design – Preventing wire breakage at connection points

INSULATED TERMINAL APPLICATIONS BY INDUSTRY

AUTOMOTIVE APPLICATIONS

Specialized Requirements:

- Vibration resistance – Withstanding constant mechanical stress

- Temperature cycling – Performing under extreme temperature variations

- Chemical resistance – Resisting automotive fluids and cleaners

- Compact design – Fitting in space-constrained environments

- Color coding – Enabling circuit identification and troubleshooting

Recommended Terminal Types:

- Bullet terminals for quick-disconnect applications

- Ring terminals for permanent chassis grounding

- Spade terminals for accessory connections

- Heat-shrink terminals for weather-sealed connections

INDUSTRIAL CONTROL SYSTEMS

Critical Performance Factors:

- Long-term reliability – Maintaining connections over equipment lifetime

- High current capacity – Handling motor and heating loads

- Safety compliance – Meeting industrial electrical codes

- Maintenance access – Enabling routine inspection and testing

- Environmental protection – Resisting industrial contaminants

Optimal Terminal Selection:

- Ring terminals for motor and transformer connections

- Spade terminals for control circuit applications

- Quick disconnects for maintenance-accessible connections

- Insulated butt splices for field wiring modifications

MARINE AND OUTDOOR APPLICATIONS

Environmental Challenges:

- Moisture protection – Preventing corrosion and electrical failure

- Salt spray resistance – Withstanding marine environments

- UV stability – Maintaining insulation integrity under sunlight

- Temperature extremes – Performing in varying weather conditions

- Chemical exposure – Resisting cleaning agents and pollutants

Marine-Grade Solutions:

- Heat-shrink terminals with adhesive lining

- Tinned copper conductors for corrosion resistance

- UV-stable insulation materials

- Sealed connection systems

- Stainless steel hardware where applicable

INSTALLATION BEST PRACTICES FOR INSULATED TERMINALS

PROPER CRIMPING TECHNIQUES

Step-by-Step Crimping Process:

- Strip wire to proper length – Match terminal manufacturer specifications

- Select appropriate crimping tool – Use tool designed for specific terminal type

- Position wire correctly – Ensure conductor reaches terminal barrel end

- Apply crimping pressure – Use recommended tool settings for wire gauge

- Inspect crimped connection – Verify proper mechanical and electrical integrity

Expert Installation Tip: Always use crimping tools specifically designed for insulated terminals. Standard tools may damage insulation or create poor connections that fail over time.

SAFETY VERIFICATION PROCEDURES

Mandatory Safety Checks:

- Visual inspection – Verify intact insulation with no cracks or damage

- Pull test – Confirm mechanical connection strength

- Continuity test – Validate electrical connection integrity

- Insulation test – Verify proper voltage isolation

- Environmental check – Ensure appropriate terminal rating for application

Professional Safety Warning: Never attempt to repair damaged insulated terminals. Replace any terminal showing signs of insulation damage, overheating, or mechanical stress. Damaged insulation creates serious electrical hazards.

FREQUENTLY ASKED QUESTIONS ABOUT INSULATED TERMINAL MANUFACTURERS

What makes insulated terminals different from bare terminals?

Insulated terminals feature protective polymer coverings that prevent electrical contact, short circuits, and environmental contamination. This insulation provides essential safety protection while maintaining electrical performance, making them mandatory for many applications under electrical codes.

How do I determine the correct wire gauge for insulated terminals?

Terminal manufacturers provide wire gauge charts matching terminal sizes to conductor specifications. Always select terminals that accommodate your wire gauge with proper crimping contact. Using oversized or undersized terminals creates unreliable connections that may fail over time.

What certifications should I look for when selecting insulated terminals?

Essential certifications include UL 486A/486B for general applications, CSA C22.2 No. 65 for Canadian installations, and IEC 60999 for international compliance. Marine applications require additional certifications for moisture and corrosion resistance.

Can I mix different manufacturers’ insulated terminals in the same installation?

While physically possible, mixing manufacturers is not recommended for critical applications. Different manufacturers use varying insulation materials, crimping specifications, and quality standards. Standardizing on a single manufacturer ensures consistent performance and simplified maintenance.

How often should insulated terminal connections be inspected?

Inspection frequency depends on application severity and environmental conditions. General industrial applications typically require annual inspection, while critical systems or harsh environments may need quarterly or monthly checks. Always follow manufacturer recommendations and applicable electrical codes.

What’s the difference between PVC and nylon insulation on terminals?

Nylon insulation offers superior temperature resistance (up to 105°C vs 80°C for PVC) and better chemical resistance. PVC provides adequate performance for general applications at lower cost. Choose nylon for high-temperature or chemically aggressive environments.

How do I prevent corrosion in insulated terminal connections?

Select terminals with tinned copper conductors and appropriate environmental ratings. Use dielectric grease where recommended, ensure proper environmental sealing, and maintain connections according to manufacturer specifications. Consider heat-shrink terminals for maximum environmental protection.

What wire stripping length should I use for insulated terminals?

Strip wire to match the terminal barrel length, typically 1/4″ to 3/8″ for standard terminals. Insufficient stripping creates poor connections, while excessive stripping exposes conductors beyond the insulation protection. Always follow manufacturer specifications.

QUALITY CONTROL AND TESTING STANDARDS

Manufacturing Quality Assurance

Critical Quality Control Points:

- Incoming material inspection – Verifying copper and insulation material specifications

- Dimensional accuracy – Ensuring terminals meet published specifications

- Crimping force testing – Validating mechanical connection strength

- Electrical performance – Confirming current-carrying capacity and voltage ratings

- Environmental testing – Verifying temperature, moisture, and chemical resistance

- Insulation integrity – Testing dielectric strength and breakdown voltage

Performance Testing Standards

Required Performance Tests:

- Current cycling – Validating performance under thermal stress

- Vibration testing – Ensuring mechanical reliability in dynamic applications

- Temperature cycling – Confirming performance across operating range

- Salt spray testing – Validating corrosion resistance for marine applications

- Pull strength testing – Verifying mechanical connection integrity

- Insulation resistance – Confirming electrical isolation properties

FUTURE TRENDS IN INSULATED TERMINAL TECHNOLOGY

Advanced Materials Development

Emerging Insulation Technologies:

- High-temperature polymers – Enabling operation above 150°C

- Self-healing materials – Automatically sealing minor insulation damage

- Conductive polymers – Providing both insulation and EMI shielding

- Bio-based materials – Reducing environmental impact

- Smart materials – Indicating connection status through color change

Industry 4.0 Integration

Next-Generation Features:

- RFID identification – Enabling automated inventory and maintenance tracking

- Temperature monitoring – Providing real-time connection health data

- Predictive maintenance – Using sensors to predict connection failure

- Digital documentation – QR codes linking to installation and maintenance records

- Augmented reality support – Providing installation guidance through AR systems

Sustainability Initiatives

Environmental Improvements:

- Recyclable insulation materials – Reducing landfill waste

- Lead-free formulations – Meeting environmental regulations

- Reduced packaging – Minimizing shipping and storage waste

- Energy-efficient manufacturing – Reducing production carbon footprint

- Extended product life – Designing for longer service life

TERMINAL SELECTION DECISION MATRIX

| Application Type | Recommended Manufacturer | Terminal Type | Key Features | Typical Cost Range |

|---|---|---|---|---|

| General Industrial | Tonful Electric, TE Connectivity | Ring, Spade | UL Listed, 600V rating | $0.05-$0.50 |

| Automotive | Molex, 3M | Bullet, Quick Disconnect | Vibration resistant, color coded | $0.08-$0.75 |

| Marine/Outdoor | 3M, Phoenix Contact | Heat Shrink, Sealed | Moisture protection, UV stable | $0.15-$1.25 |

| High Temperature | TE Connectivity, Phoenix | Nylon Insulated | 105°C rating, flame retardant | $0.12-$0.90 |

| High Voltage | Tonful Electric, 3M | Heavy Duty Ring | 1000V+ rating, thick insulation | $0.25-$2.00 |

CONCLUSION: SELECTING THE OPTIMAL INSULATED TERMINAL MANUFACTURER

Choosing the right insulated terminal manufacturer requires balancing performance requirements, safety compliance, and application-specific needs. The top manufacturers highlighted in this guide represent industry leaders who consistently deliver safe, reliable connectivity solutions.

Key Selection Criteria Summary:

- Safety certifications ensuring code compliance and user protection

- Technical specifications matching your voltage, current, and environmental requirements

- Quality assurance providing long-term reliability and consistent performance

- Application expertise offering specialized solutions for your specific industry

- Technical support assisting with selection, installation, and troubleshooting

Remember that insulated terminals are critical safety components protecting against electrical hazards. Investing in high-quality products from reputable manufacturers ensures reliable performance and regulatory compliance.

Expert Recommendation: For comprehensive insulated terminal solutions backed by technical expertise and industry-leading quality control, contact Tonful Electric’s technical specialists at sales@tonful.com. Our experienced engineers can help you select the optimal terminals for your specific application requirements while ensuring safety compliance and long-term reliability.

About Tonful Electric: As a leading low-voltage electrical manufacturer, Tonful Electric specializes in producing precision-engineered insulated terminals that exceed international safety standards. Our advanced manufacturing facility and comprehensive quality control systems ensure every product delivers exceptional reliability for critical electrical connections.