In the demanding world of commercial transportation, the reliability of every component counts. From the engine to the smallest electrical contact, fleet uptime depends on quality. Among these critical components, the Auto Combination Switch plays a pivotal role in driver safety and vehicle operation. For commercial vehicle manufacturers, fleet managers, and aftermarket distributors, sourcing a high-quality 12V Auto Combination Switch is not just about replacing a part—it’s about ensuring the seamless integration of control systems in trucks, buses, and heavy-duty machinery.

At Tonful Electric, we understand that B2B clients require precision, durability, and electrical stability. As a professional manufacturer specialized in low-voltage electrical appliances, we provide insights into why the Auto Combination Switch is vital for commercial vehicles and how to select the right solution for your manufacturing or distribution needs.

What is an Auto Combination Switch?

An Auto Combination Switch, often referred to as a multi-function switch or stalk switch, is a complex electromechanical device usually mounted on the steering column. It serves as the central command hub for the driver, consolidating various essential functions into one accessible interface.

In a standard 12V commercial vehicle system, this switch typically controls:

- Lighting Systems: Headlights (high/low beam), parking lights, and turn signals.

- Wiper and Washer Systems: Windshield wiper speed control and fluid activation.

- Auxiliary Controls: Fog lights, cruise control, and horn functions.

Unlike passenger cars, commercial vehicles operate in harsh environments with higher usage cycles. Therefore, a commercial-grade Auto Combination Switch must be engineered to withstand rigorous daily use, vibration, and temperature fluctuations.

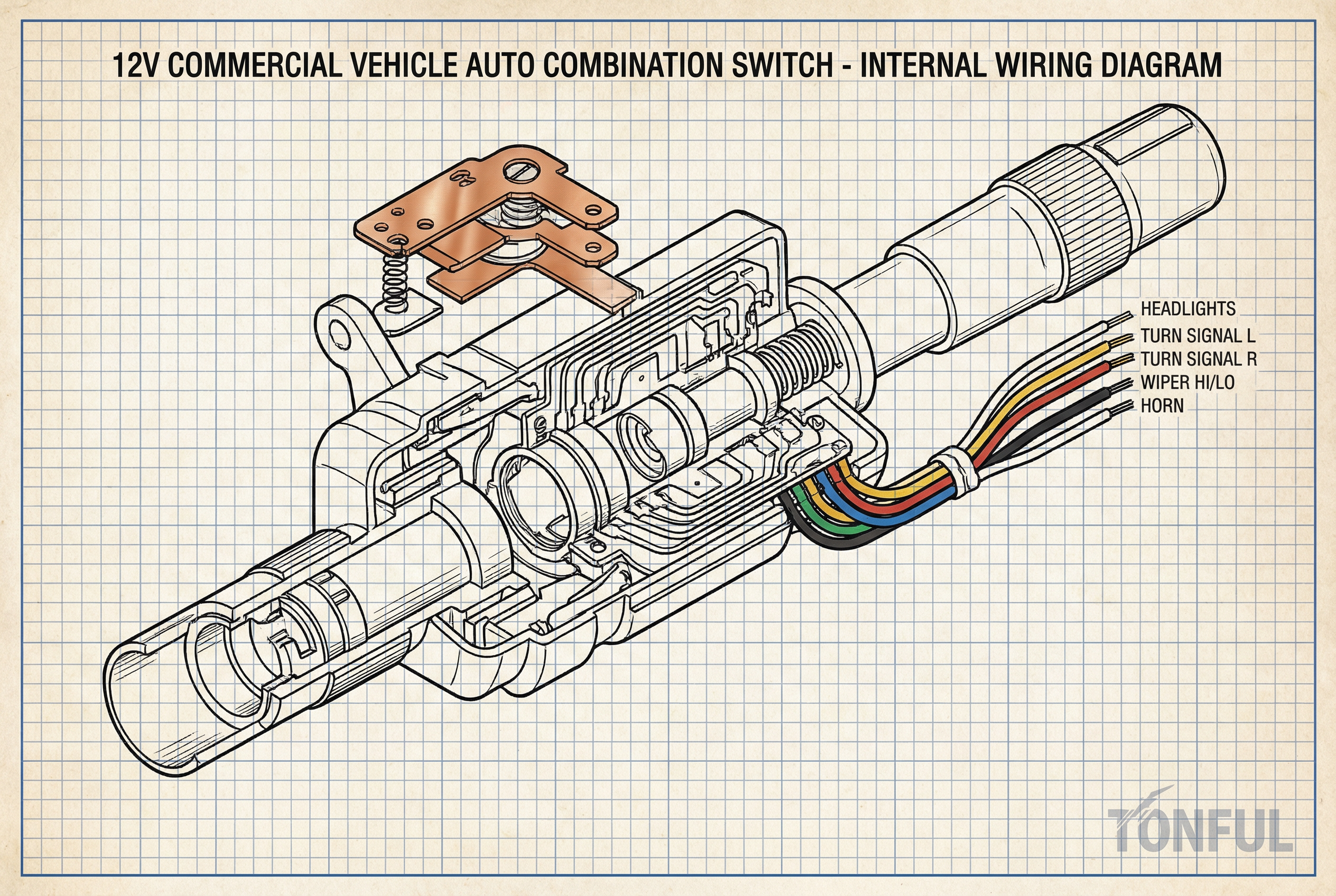

Key Technical Components and Mechanism

Understanding the internal architecture of a switch helps in appreciating the quality difference between generic parts and professional-grade components from manufacturers like Tonful Electric.

1. Contact Points

The heart of the switch lies in its electrical contacts. In high-quality 12V switches, these contacts are often made from copper alloys or plated with silver to reduce electrical resistance and prevent arcing. Poor quality contacts can lead to signal failure—a critical safety risk for commercial trucks.

2. Mechanical Detents

The “click” feel when a driver engages a turn signal is created by mechanical detents. These must be precision-engineered to provide tactile feedback without wearing out over thousands of cycles.

3. Housing Materials

Commercial vehicles are exposed to UV rays, dust, and moisture. The housing of a robust Auto Combination Switch is typically crafted from high-grade engineering plastics (like PA66 or ABS) that offer thermal stability and impact resistance.

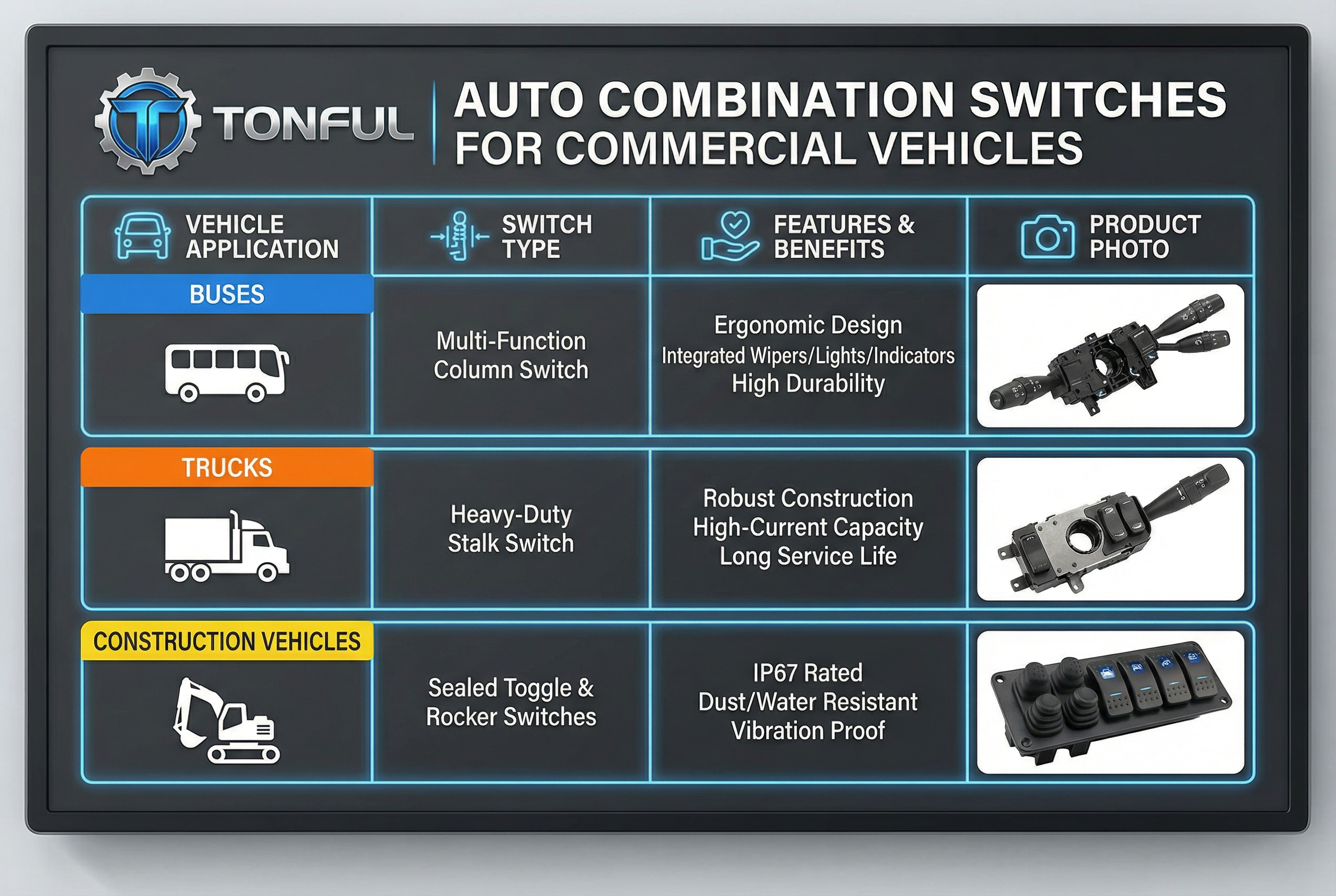

Applications Across Commercial Sectors

The versatility of the Auto Combination Switch makes it a universal requirement across the heavy-duty automotive industry. However, specifications may vary depending on the vehicle type.

Heavy-Duty Trucks

Long-haul trucks require switches that can endure constant use. The turn signal function, in particular, sees frequent activation. A 12V Auto Combination Switch for trucks must prioritize ergonomic design to reduce driver fatigue.

Buses and Coaches

Safety is paramount in passenger transport. Bus switches often integrate additional controls for interior lighting or door operations. Reliability here is non-negotiable to comply with public transport safety regulations.

Construction and Agricultural Machinery

For excavators, loaders, and tractors, the switch must be sealed against dust and debris. Tonful Electric designs switches that maintain conductivity even in dusty construction sites or humid agricultural fields.

Manufacturing Excellence: The Tonful Standard

In the B2B market, consistency is key. OEMs need to know that the 1,000th switch they receive is as reliable as the first. This is where Tonful Electric’s expertise in low-voltage electrical manufacturing becomes a strategic advantage for our partners.

Rigorous Quality Control

Manufacturing an Auto Combination Switch involves precise injection molding, metal stamping, and assembly.

At Tonful Electric, our quality control process includes:

- Life Cycle Testing: Simulating years of usage to ensure mechanical longevity.

- Electrical Load Testing: Verifying that the switch handles the 12V current without overheating or voltage drop.

- Environmental Testing: Exposing units to extreme temperatures and vibrations to mimic real-world commercial driving conditions.

OEM Customization Capabilities

One size does not fit all in the commercial sector. We work closely with vehicle manufacturers to customize pin configurations, stalk lengths, and button layouts to match specific dashboard ergonomics and electrical architectures.

Installation and Compatibility

For aftermarket distributors and repair shops, ease of installation is a major selling point. A well-designed 12V Auto Combination Switch should feature plug-and-play connectors that match OEM wire harnesses, reducing vehicle downtime.

When selecting a switch, consider:

- Pin Configuration: Ensure the connector matches the vehicle’s harness (e.g., 8-pin vs. 12-pin).

- Mounting Interface: The switch must fit securely onto the steering column without play.

- Function Mapping: Verify that all integrated functions (wipers, lights) correspond to the vehicle’s ECU programming.

Why Partner with Tonful Electric?

Sourcing low-voltage electrical components requires a partner who understands the intricacies of the automotive supply chain.

- Industry Expertise: With years of experience in low-voltage electrics, we understand the physics of arcing, resistance, and material degradation better than generalist trading companies.

- B2B Focus: Our production lines are optimized for volume orders, ensuring competitive pricing for wholesalers and OEMs.

- Global Standards: Our products are manufactured to meet international safety and quality standards, making them suitable for global markets.

Conclusion

The 12V Auto Combination Switch is more than just a lever on the steering column; it is a critical interface that connects the driver to the vehicle’s safety systems. For commercial vehicles, where reliability translates directly to profitability, settling for inferior components is not an option.

Tonful Electric stands ready to supply high-performance, durable, and precision-engineered switches that keep commercial fleets moving. whether you are an OEM looking for a production partner or a distributor seeking reliable aftermarket parts, our expertise in low-voltage electrics ensures you get the best product on the market.

Ready to upgrade your supply chain with premium Auto Combination Switches?

Contact the Tonful Electric sales team today for specifications, catalogs, and B2B pricing. Let’s drive the industry forward together.