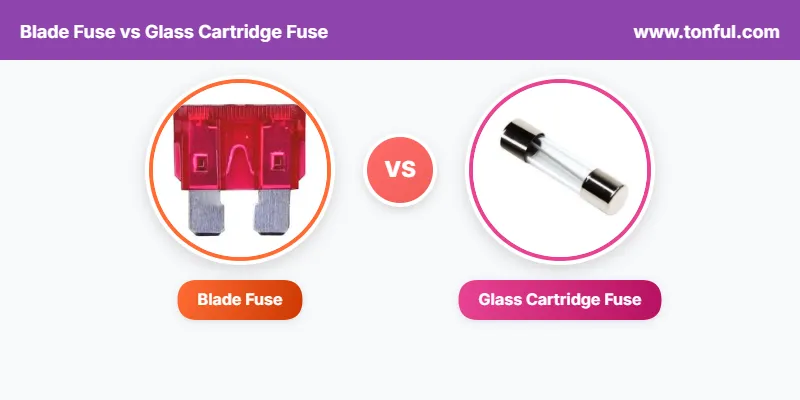

A blade fuse differs from a glass cartridge fuse primarily in its design, installation method, and application. Blade fuses use two flat metal prongs that plug into spring-loaded terminals, making them quick to replace without tools. Glass cartridge fuses feature cylindrical metal end caps with a visible glass tube body that requires mounting clips or holders. Blade fuses dominate modern automotive applications, while glass cartridge fuses remain common in older vehicles, household electronics, and industrial equipment.

Understanding these differences helps you choose the right fuse for your electrical system, ensure proper protection, and make safe, code-compliant repairs.

What Are Blade Fuses and Glass Cartridge Fuses?

Blade Fuse Definition

A blade fuse is a flat, plastic-enclosed circuit protection device with two exposed metal prongs (blades) extending from the bottom. The fuse element sits inside a colored plastic housing that indicates its amperage rating. You insert blade fuses directly into automotive fuse blocks or electrical panels using a simple push-fit connection. The design eliminates the need for separate holders or mounting hardware.

Glass Cartridge Fuse Definition

A glass cartridge fuse is a cylindrical circuit protection device with metal end caps connected by a visible fuse element running through a clear or tinted glass tube. You install these fuses by placing them into spring clips, panel-mount holders, or inline fuse holders. The transparent housing allows you to visually inspect whether the fuse element has blown without removing it from the circuit.

Key Differences: Blade Fuse vs Glass Cartridge Fuse

Here is a table that shows the primary differences between blade fuses and glass cartridge fuses:

| Feature | Blade Fuse | Glass Cartridge Fuse |

|---|---|---|

| Design | Flat plastic body with metal prongs | Cylindrical glass tube with metal caps |

| Installation | Push-fit into fuse blocks | Requires clips or holders |

| Visual Inspection | Opaque (cannot see element) | Transparent (can see blown element) |

| Size Standardization | Mini, Standard, Maxi formats | Multiple diameters and lengths |

| Primary Applications | Modern automotive systems | Older vehicles, home electronics, industrial |

| Amperage Indication | Color-coded plastic housing | Printed text or color bands |

| Tool Requirements | Hand installation (puller recommended) | Hand installation |

| Vibration Resistance | Excellent (secure terminal grip) | Good (depends on holder quality) |

| Space Efficiency | High (compact fuse blocks) | Moderate (requires holder space) |

| Cost Per Unit | $0.50-$2.00 | $0.25-$1.50 |

Detailed Technical Comparison

Here is a table that shows the technical specifications for both fuse types:

| Specification | Blade Fuse | Glass Cartridge Fuse |

|---|---|---|

| Voltage Ratings | 32V DC typical (automotive) | 125V, 250V AC/DC options |

| Amperage Range | 0.5A to 40A (standard sizes) | 0.1A to 30A (common range) |

| Response Time | Fast-acting or time-delay | Fast-acting, time-delay, or slow-blow |

| Operating Temperature | -40°F to 257°F (-40°C to 125°C) | -40°F to 302°F (-40°C to 150°C) |

| Breaking Capacity | 1000A to 10,000A | 35A to 10,000A (varies by type) |

| Standards Compliance | SAE J1284, ISO 8820 | UL 248, IEC 60127 |

| Terminal Contact | Dual blade connection | End cap contact |

| Housing Material | Polycarbonate or nylon | Borosilicate glass or ceramic |

Applications and Use Cases

Where You Use Blade Fuses

Automotive Applications:

- Modern cars and trucks (1980s-present)

- Fuse panels under dashboard and hood

- Individual circuit protection (lights, radio, power windows)

- Trailer wiring harness connections

- Automotive accessories and aftermarket electronics

Marine Applications:

- Boat electrical systems

- Marine electronics protection

- Bilge pump circuits

- Navigation equipment

Recreational Vehicles:

- RV fuse panels

- Motorhome electrical systems

- Travel trailer circuits

Where You Use Glass Cartridge Fuses

Household Electronics:

- Older stereo equipment and amplifiers

- Vintage televisions and radios

- Power supply protection

- Microwave ovens

- Christmas lights and decorative lighting

Older Automotive:

- Classic cars (pre-1980s)

- Vintage motorcycles

- Agricultural equipment

- Industrial vehicles

Industrial Equipment:

- Control panels

- Instrumentation circuits

- HVAC systems

- Test and measurement equipment

Specialized Applications:

- Precision electronics requiring visible inspection

- High-voltage circuits (250V applications)

- Equipment requiring UL or IEC certification

What Makes Each Fuse Type Different?

Blade Fuse Advantages

Quick Replacement Without Tools: You can remove and install blade fuses by hand in seconds. The push-fit design eliminates screws, clips, or tools for routine maintenance.

Secure Mechanical Connection: The spring-loaded terminals in blade fuse blocks grip both metal prongs firmly, providing excellent vibration resistance critical in automotive and mobile applications.

Color-Coded Identification: Each amperage rating features a distinct color (2A tan, 5A tan, 10A red, 15A blue, 20A yellow, 25A clear, 30A green). You can identify ratings instantly without reading text.

Space-Efficient Design: Blade fuses allow high-density packing in fuse blocks, saving valuable space in modern vehicles with dozens of circuits requiring individual protection.

Standardized Formats: Three main sizes (Mini, Standard ATO/ATC, Maxi) cover most automotive needs with clear specifications defined by SAE and ISO standards.

Glass Cartridge Fuse Advantages

Visual Inspection Capability: The transparent glass housing lets you see whether the internal element has melted without removing the fuse from its holder, saving diagnostic time.

Higher Voltage Ratings: Glass cartridge fuses commonly handle 125V and 250V AC applications, making them suitable for household electronics and industrial equipment beyond automotive use.

Universal Availability: Decades of standardization mean glass cartridge fuses are available worldwide in hardware stores, electronics shops, and industrial suppliers.

Precise Breaking Characteristics: Glass cartridge fuses offer refined response curves (fast-acting, time-delay, slow-blow) critical for sensitive electronic equipment protection.

Cost-Effectiveness: Generally less expensive per unit than blade fuses, especially for lower amperage ratings used in electronics.

How to Choose Between Blade and Glass Cartridge Fuses

Selection Criteria

Choose Blade Fuses When:

- Working with modern automotive systems (1980s-present)

- You need vibration-resistant connections

- Quick tool-free replacement matters

- Space efficiency is important

- Operating voltage is 32V DC or below

- Color-coding simplifies identification

Choose Glass Cartridge Fuses When:

- Replacing fuses in older equipment with existing holders

- Visual inspection capability is valuable

- Working with 125V or 250V circuits

- UL or IEC certification is required

- Budget constraints favor lower-cost options

- Precision response curves matter for sensitive electronics

Safety and Compliance Considerations

⚠️ SAFETY WARNING: Always use the exact amperage rating specified by the equipment manufacturer. Using higher-rated fuses can cause wire overheating, fire hazards, and equipment damage. Never substitute a fuse type unless explicitly approved by the manufacturer.

Code Compliance Requirements:

- Automotive fuses must meet SAE J1284 standards for blade fuses

- Household and commercial fuses require UL 248 certification

- Marine applications need ABYC E-11 compliant fuses

- European equipment requires IEC 60127 compliance

Expert Tip: When working with automotive electrical systems, always disconnect the negative battery terminal before replacing fuses to prevent short circuits and potential injury.

Step-by-Step: How to Replace Each Fuse Type

Replacing a Blade Fuse

- Turn off ignition and accessories to eliminate power draw

- Locate the fuse panel (check owner’s manual for location)

- Identify the blown fuse using the fuse diagram on panel cover

- Use a fuse puller (or needle-nose pliers) to grasp the fuse top

- Pull straight up firmly to release the fuse from terminals

- Check the fuse element through the plastic top (broken metal strip indicates blown fuse)

- Insert new fuse with matching amperage rating (verify color code)

- Push firmly until seated completely in both terminals

- Test the circuit by turning on the affected accessory

- If fuse blows immediately, seek professional diagnosis for underlying electrical fault

Replacing a Glass Cartridge Fuse

- Disconnect power to the equipment or circuit

- Remove fuse holder cap or open the inline fuse holder

- Extract the fuse from spring clips by pulling gently

- Inspect the glass tube for broken or melted fuse wire

- Check voltage and amperage ratings printed on metal caps

- Install replacement fuse matching exact specifications

- Secure holder cap or close inline holder firmly

- Restore power and test circuit operation

- If fuse fails repeatedly, have a qualified electrician inspect the circuit for shorts or overload conditions

Expert Tip: Keep a selection of replacement fuses in your vehicle or with equipment. Store them in the original packaging to prevent terminal corrosion and maintain organization by amperage rating.

Troubleshooting Common Fuse Problems

Blade Fuse Issues

Fuse Won’t Stay Seated:

- Terminals may be worn or spread apart

- Replace the entire fuse block if terminals have lost spring tension

- Ensure you’re using the correct fuse size (Mini vs Standard vs Maxi)

Fuse Keeps Blowing:

- Electrical short in the protected circuit

- Overloaded circuit exceeding fuse rating

- Wrong amperage fuse installed

- Seek professional electrical diagnosis

Corrosion on Blade Terminals:

- Clean terminals with electrical contact cleaner

- Use dielectric grease on blades before installation

- Address water intrusion into fuse panel

Glass Cartridge Fuse Issues

Fuse Holder Clips Loose:

- Replace worn spring clips

- Ensure correct fuse diameter for holder

- Check for corrosion affecting clip tension

Cannot Determine if Fuse is Blown:

- Tinted glass may obscure view

- Use multimeter to check continuity

- Replace with new fuse if uncertain

Repeated Fuse Failure:

- Calculate actual circuit load vs fuse rating

- Inspect for damaged wiring or components

- Consider time-delay fuse for motor circuits

Expert Tip: If a circuit repeatedly blows fuses of the correct rating, never install a higher-rated fuse. This indicates an electrical problem requiring professional diagnosis and repair.

Professional Recommendations and When to Seek Help

DIY-Appropriate Tasks

- Replacing blown fuses in accessible panels

- Installing fuses in trailer wiring

- Maintaining spare fuse inventory

- Basic visual inspection of fuses

Require Professional Assistance

- Diagnosing circuits with repeated fuse failures

- Modifying fuse ratings or types

- Adding new circuits to existing panels

- Electrical issues after water damage

- Any situation involving main power distribution

Certification Note: Automotive electrical work typically doesn’t require licensing for personal vehicles, but commercial vehicle repairs may need ASE certification. Household electrical work requiring fuse panel modifications needs a licensed electrician in most jurisdictions.

Quick Reference Guide: Blade Fuse Color Codes

| Amperage | Color | Common Applications |

|---|---|---|

| 2A | Gray | Small electronics |

| 3A | Violet | Accessory circuits |

| 5A | Tan | Interior lights, instrument panel |

| 7.5A | Brown | Radio memory, small accessories |

| 10A | Red | Power windows, cigarette lighter |

| 15A | Blue | Larger accessories, heated seats |

| 20A | Yellow | Horn, HVAC blower |

| 25A | Clear/White | Defrost, heated mirrors |

| 30A | Green | Power seats, sunroof |

| 40A | Orange | Heavy accessories |

Frequently Asked Questions

Can I replace a glass cartridge fuse with a blade fuse?

No, you cannot directly replace a glass cartridge fuse with a blade fuse without modifying the holder or panel. The mounting systems are incompatible. Glass fuses require clip or socket holders, while blade fuses need terminal blocks. Attempting to force-fit different fuse types creates safety hazards and unreliable connections. Always use the fuse type specified by the equipment manufacturer.

Why are blade fuses more common in modern cars?

Blade fuses became standard in automotive applications because they offer superior vibration resistance, faster replacement, and higher reliability in harsh environments. The push-fit design eliminates the corrosion and loosening issues that affected glass fuse clip holders. Automakers adopted blade fuses industry-wide starting in the 1980s as vehicle electronic systems became more complex and required more individual circuits.

How can I tell if a blade fuse is blown if I cannot see through it?

You can check a blade fuse three ways: First, use a test light or multimeter to check for continuity across the two blade terminals. Second, look through the top of the plastic housing in bright light to see if the metal strip is intact. Third, swap the suspect fuse with a known good fuse of the same rating from a non-critical circuit. Many fuse pullers include a small continuity tester built into the handle.

Are slow-blow fuses available in blade format?

Yes, time-delay (slow-blow) blade fuses are available, though less common than in glass cartridge format. Look for blade fuses marked “ATM” (mini time-delay) or specific time-delay ratings. These fuses allow temporary current surges without blowing, making them ideal for motor circuits like power windows or cooling fans. Always verify your equipment specifies time-delay operation before substituting a standard fast-acting blade fuse.

What happens if I use a higher amperage fuse than specified?

Using a higher-rated fuse removes the safety protection designed into the circuit. The circuit wiring may overheat during overload conditions, potentially causing melted insulation, electrical fires, or equipment damage. Fuses are intentionally the weakest link in the circuit—they fail first to protect expensive components and prevent hazards. Never exceed manufacturer-specified fuse ratings. If proper-rated fuses blow repeatedly, the circuit has an underlying problem requiring professional diagnosis.

Can blade fuses be used in marine applications?

Yes, blade fuses can be used in marine environments, but you should choose marine-grade fuse blocks with corrosion-resistant terminals and protective covers. Marine blade fuse blocks typically feature tinned copper terminals, sealed housings, and conform to ABYC E-11 standards. The harsh marine environment with salt spray and moisture requires fuse blocks specifically designed for these conditions. Standard automotive fuse blocks may corrode quickly in marine use.

Why do some glass fuses have sand inside?

High-rupture-capacity (HRC) glass fuses contain silica sand surrounding the fuse element. When excessive current melts the element, the sand absorbs the arc energy and extinguishes it quickly. This prevents the fuse from exploding or the arc from maintaining current flow. HRC fuses are essential for circuits with high available fault current, such as mains-powered equipment. Never replace an HRC fuse with a standard glass fuse—the equipment requires the higher breaking capacity.

Do blade fuses have polarity or direction?

No, blade fuses have no polarity and can be installed in either direction. Current flows through the fuse element regardless of orientation. However, the fuse should be fully seated with both blades making firm contact with the terminal springs. Some fuse blocks position circuits so that the hot (powered) side comes from a specific direction, but the fuse itself functions identically either way.

Conclusion: Making the Right Fuse Choice

The difference between blade fuses and glass cartridge fuses goes beyond physical design—it reflects distinct applications, installation requirements, and protection characteristics. Blade fuses excel in modern automotive and mobile applications where vibration resistance, quick replacement, and space efficiency matter most. Glass cartridge fuses remain the best choice for household electronics, industrial equipment, and any application requiring visual inspection, higher voltage ratings, or specific UL/IEC certifications.

Always match the fuse type, voltage rating, amperage, and response characteristics specified by your equipment manufacturer. When circuits fail repeatedly, invest in professional electrical diagnosis rather than trying different fuses or higher ratings. Proper fuse selection and replacement protect both your equipment investment and your safety.

Expert Recommendation: Maintain a properly organized spare fuse inventory for your vehicles and equipment. Label storage containers clearly by amperage rating and replace fuses at the first sign of corrosion, physical damage, or after they’ve blown. Quality circuit protection is inexpensive insurance against costly electrical damage and potential fire hazards.