Are you searching for reliable cord end terminal manufacturers to ensure secure electrical connections in your industrial applications? This comprehensive guide examines the leading cord end terminal suppliers of 2025, comparing their technologies, certifications, and market positions to help you make informed decisions about electrical termination solutions.

WHAT ARE CORD END TERMINALS AND WHY ARE THEY ESSENTIAL?

Cord end terminals (also known as ferrules or wire end sleeves) are precision-engineered electrical components that provide secure termination for stranded wire conductors. These critical components, produced by specialized cord end terminal manufacturers, prevent wire fraying, reduce contact resistance, and ensure reliable connections in industrial control systems.

Here’s why cord end terminals are crucial for your electrical systems:

- Wire Protection: Prevent conductor strand separation and fraying

- Connection Reliability: Eliminate loose strands that cause arc faults

- Installation Efficiency: Simplify wire insertion into terminal blocks

- Code Compliance: Meet electrical safety standards and regulations

- System Longevity: Reduce maintenance and failure rates

Expert Tip: Using cord end terminals can reduce connection failures by up to 90% compared to bare stranded wire connections.

HOW CORD END TERMINALS SAFEGUARD YOUR ELECTRICAL SYSTEMS

Understanding how cord end terminals work helps you appreciate the engineering expertise behind leading cord end terminal manufacturers. These components employ precision manufacturing to maintain conductor integrity while providing optimal electrical performance.

Here’s how cord end terminals protect your systems:

| Protection Method | Benefit | Application |

|---|---|---|

| Strand Containment | Prevents wire fraying and short circuits | All stranded wire connections |

| Contact Optimization | Reduces resistance and heat generation | High-current applications |

| Insertion Guidance | Ensures proper seating in terminal blocks | Automated manufacturing |

| Color Coding | Simplifies identification and troubleshooting | Complex control panels |

Leading cord end terminal manufacturers differentiate themselves through superior crimping technologies, higher current ratings, innovative insulation materials, and comprehensive wire gauge coverage that meets diverse industrial requirements.

GLOBAL CORD END TERMINAL MARKET: 2025 ANALYSIS

The global cord end terminal market has reached $2.1 billion in 2024, with projections indicating robust growth at a CAGR of 5.2% through 2030. This expansion is driven by:

- Industrial Automation Growth: Increasing demand for reliable connections

- Renewable Energy Expansion: Solar and wind installations requiring quality terminations

- Electric Vehicle Infrastructure: High-voltage applications demanding certified components

- Building Automation: Smart systems requiring standardized connections

- Manufacturing Modernization: Industry 4.0 implementations across all sectors

Regional Market Distribution:

| Region | Market Share | Growth Rate | Key Drivers |

|---|---|---|---|

| Europe | 35% | 4.8% | DIN rail standardization, automation |

| Asia-Pacific | 32% | 7.1% | Manufacturing expansion, infrastructure |

| North America | 25% | 4.5% | Industrial modernization, safety standards |

| Rest of World | 8% | 6.2% | Infrastructure development |

WHAT TO LOOK FOR WHEN CHOOSING CORD END TERMINAL MANUFACTURERS

When evaluating potential cord end terminal suppliers for your electrical needs, consider these critical factors:

1. CERTIFICATION AND COMPLIANCE

Reputable cord end terminal manufacturers obtain rigorous certifications:

- UL 486E: Underwriters Laboratories standard for cord end terminals

- IEC 60947-7-4: International standard for screw-type terminals

- DIN 46228: German standard for cord end terminals

- CSA C22.2: Canadian Standards Association certification

- RoHS Compliance: Environmental safety requirements

2. TECHNICAL SPECIFICATIONS

Compare these key aspects across different cord end terminal manufacturers:

| Specification | Importance | Typical Range |

|---|---|---|

| Wire Gauge Range | Installation flexibility | 22 AWG to 4/0 AWG |

| Current Rating | Load capacity | 1A to 1000A |

| Temperature Rating | Environmental durability | -40°C to +105°C |

| Insulation Length | Safety compliance | 6mm to 25mm |

| Crimp Quality | Connection reliability | Class 1 or Class 2 |

3. QUALITY ASSURANCE

Industry-leading cord end terminal manufacturers provide:

- 100% electrical testing of every terminal

- Dimensional verification to ensure proper fit

- Pull-out force testing for mechanical integrity

- Corrosion resistance testing for longevity

- Batch traceability for quality control

4. PRODUCT RANGE AND AVAILABILITY

The best cord end terminal suppliers offer:

- Complete wire gauge coverage from 28 AWG to 4/0 AWG

- Multiple insulation colors for circuit identification

- Uninsulated and insulated versions for various applications

- Twin ferrules for parallel conductors

- Custom solutions for specialized requirements

TOP 10 CORD END TERMINAL MANUFACTURERS OF 2025

Our comprehensive analysis of the electrical component market has identified these industry leaders:

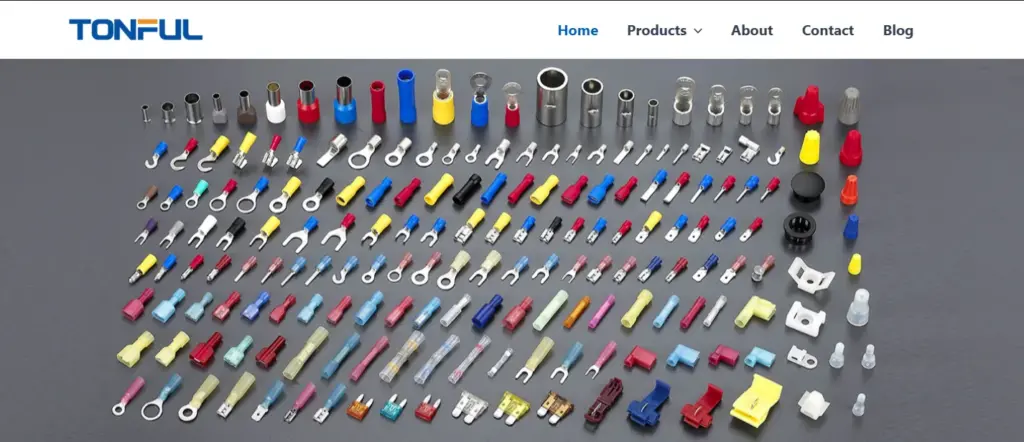

1. TONFUL ELECTRIC: PRECISION ENGINEERING EXCELLENCE

Website: https://tonful.com

Founded with a commitment to precision manufacturing, Tonful Electric has rapidly established itself as a premier cord end terminal manufacturer through innovative design and exceptional quality control. The company specializes in low-voltage electrical components with particular strength in:

- Advanced copper alloy construction for superior conductivity

- Precision crimping technology ensuring optimal connection quality

- Comprehensive wire gauge coverage from 22 AWG to 4/0 AWG

- Multiple insulation options including PVC and nylon variants

- Strict quality control with 100% electrical testing

Tonful Electric’s manufacturing facilities employ state-of-the-art production equipment and rigorous quality assurance protocols, making them the preferred choice for industrial automation and control panel applications requiring guaranteed performance.

Key Product: Tonful’s insulated cord end terminals feature precision-engineered barrels and color-coded insulation sleeves, providing exceptional crimping performance and visual identification for complex wiring systems.

2. TE CONNECTIVITY: GLOBAL CONNECTIVITY LEADER

Website: https://www.te.com

TE Connectivity stands as a global powerhouse among cord end terminal manufacturers, leveraging decades of engineering expertise and worldwide manufacturing capabilities. Their comprehensive cord end terminal portfolio features:

- Industry-leading wire range compatibility

- Advanced plating technologies for enhanced corrosion resistance

- Automotive-grade quality suitable for harsh environments

- Global availability ensuring consistent supply chains

- Technical support network spanning all major markets

TE Connectivity’s focus on automotive and industrial applications has made them particularly valuable for high-reliability systems requiring certified performance standards.

Key Product: TE’s PIDG series cord end terminals deliver exceptional crimping performance with standardized color coding for wire gauge identification.

3. PHOENIX CONTACT: INNOVATION IN CONNECTION TECHNOLOGY

Website: https://www.phoenixcontact.com

Phoenix Contact has built its reputation on German engineering excellence, becoming a leading cord end terminal supplier through continuous innovation and precision manufacturing. Their products feature:

- DIN-compliant designs meeting European standards

- Push-in compatible ferrules for tool-free installations

- Color-coded insulation for easy wire identification

- Exceptional temperature resistance for harsh environments

- Comprehensive accessories including crimping tools

Phoenix Contact’s commitment to quality and innovation has made them the preferred choice for European industrial applications and global automation projects.

Key Product: Phoenix Contact’s AI series cord end terminals offer exceptional dimensional accuracy for reliable push-in terminal compatibility.

4. WEIDMÜLLER: PRECISION GERMAN ENGINEERING

Website: https://www.weidmuller.com

Weidmüller represents the pinnacle of German engineering precision among cord end terminal manufacturers, delivering exceptional reliability through meticulous manufacturing processes. Their terminal solutions feature:

- Laser-marked identification for traceability

- High-grade copper construction ensuring optimal conductivity

- Precision crimping profiles for consistent connections

- Environmental resistance meeting IP67 standards

- Comprehensive testing protocols exceeding industry requirements

Weidmüller’s quality management systems ensure consistent performance across their entire product range, making them essential for mission-critical industrial applications.

Key Product: Weidmüller’s H series cord end terminals provide exceptional crimping reliability with color-coded insulation for systematic wire identification.

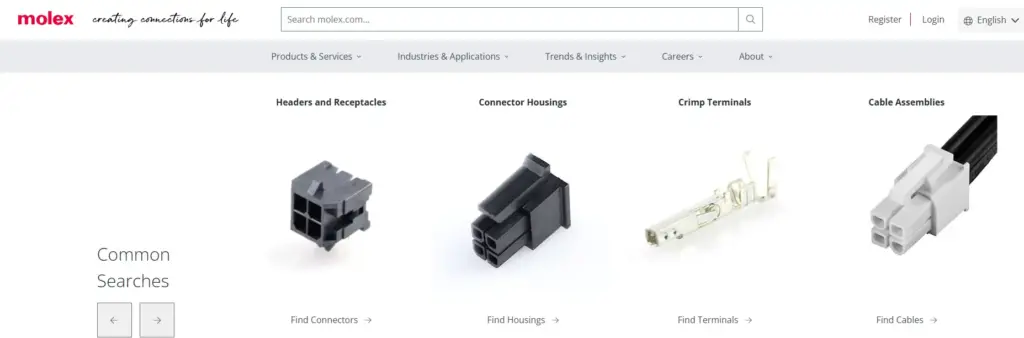

5. MOLEX: ADVANCED CONNECTION SYSTEMS

Website: https://www.molex.com

Molex has secured its position as a major cord end terminal manufacturer through continuous innovation and expansion across multiple industries. Their comprehensive product line addresses diverse application requirements with:

- Miniaturized designs for space-constrained applications

- High-temperature materials for demanding environments

- Automated manufacturing compatibility for high-volume production

- Custom engineering capabilities for specialized requirements

- Global manufacturing footprint ensuring reliable supply

Particularly strong in electronics and telecommunications applications, Molex cord end terminals excel in systems requiring precise, reliable connections in compact configurations.

Key Product: Molex’s micro-ferrules provide exceptional performance in high-density connection applications while maintaining full electrical integrity.

6. JEESOON TERMINALS CO LTD: ASIAN MANUFACTURING EXCELLENCE

Website: https://www.jeesoon.com.tw/

Jeesoon Terminals has established itself as a significant cord end terminal supplier in the Asian market through competitive pricing and reliable quality. Their product offerings include:

- Comprehensive wire gauge coverage for industrial applications

- Cost-effective solutions without compromising quality

- Fast delivery capabilities supporting just-in-time manufacturing

- Custom color options for specific identification requirements

- Bulk packaging options for high-volume users

The company has shown impressive growth in industrial automation markets, particularly in building management systems and process control applications.

Key Product: Jeesoon’s standard cord end terminals provide reliable performance at competitive price points for general industrial applications.

7. HUA WEI INDUSTRIAL CO., LTD.: INDUSTRIAL STRENGTH SOLUTIONS

Website: https://www.hwlok.com/en/index.html

Hua Wei Industrial has built its reputation as a reliable cord end terminal manufacturer through focus on industrial-grade applications and competitive manufacturing. Their products feature:

- Heavy-duty construction for demanding environments

- Wide temperature range capability for extreme conditions

- Bulk supply capabilities for large projects

- Standard compliance meeting international requirements

- Flexible packaging options accommodating various needs

Particularly strong in infrastructure and heavy industrial applications, Hua Wei terminals provide dependable performance in challenging operating conditions.

Key Product: Hua Wei’s industrial-grade cord end terminals deliver robust performance in harsh environmental conditions.

8. K.S. TERMINALS INC: PRECISION MANUFACTURING SPECIALISTS

Website: https://ksterminals.com/

K.S. Terminals has distinguished itself among cord end terminal manufacturers through precision manufacturing and attention to detail. Their approach focuses on:

- Dimensional accuracy ensuring consistent performance

- Quality control processes exceeding industry standards

- Custom crimping solutions for specialized applications

- Technical support for application engineering

- Rapid prototyping capabilities for custom requirements

The company has built strong customer loyalty through consistent quality and responsive technical support for complex application requirements.

Key Product: K.S. Terminals’ precision cord end terminals offer exceptional dimensional consistency for automated assembly processes.

9. ELECDIRECT.COM: DISTRIBUTION AND SUPPLY EXCELLENCE

Website: https://www.elecdirect.com

ElecDirect has established itself as a major distributor and cord end terminal supplier through comprehensive inventory management and customer service excellence. Their services include:

- Extensive inventory coverage of multiple manufacturer brands

- Fast shipping capabilities supporting urgent requirements

- Technical product support for selection assistance

- Volume pricing programs for large quantity purchases

- Custom packaging services for specific customer needs

Particularly valuable for customers requiring multiple brands or fast delivery, ElecDirect provides comprehensive solutions for electrical component procurement.

Key Product: ElecDirect offers comprehensive cord end terminal selection from multiple manufacturers with fast delivery options.

10. AMERICAN ELECTRICAL, INC: NORTH AMERICAN EXCELLENCE

Website: https://www.americanelectrical.com/

American Electrical has built its position as a trusted cord end terminal manufacturer through focus on North American market requirements and quality standards. Their offerings include:

- UL-listed products meeting North American standards

- Local manufacturing support for domestic projects

- Custom specification capabilities for unique requirements

- Technical documentation supporting design engineering

- Application support for proper selection and installation

The company shows particular strength in industrial control and power distribution applications requiring certified performance standards.

Key Product: American Electrical’s UL-listed cord end terminals provide certified performance for North American electrical installations.

CORD END TERMINAL TYPES AND APPLICATIONS

Leading cord end terminal manufacturers develop specialized solutions for different connection scenarios:

INSULATED CORD END TERMINALS

The most common choice for general applications, insulated cord end terminals from quality manufacturers provide:

| Feature | Benefit | Application |

|---|---|---|

| Color-coded sleeves | Wire gauge identification | Control panels, automation |

| Electrical insulation | Safety and code compliance | General industrial wiring |

| Moisture protection | Enhanced reliability | Outdoor installations |

| Standard lengths | Universal compatibility | DIN rail terminal blocks |

Ideal applications: Industrial control panels, building automation, HVAC systems, and general electrical installations.

UNINSULATED CORD END TERMINALS

Professional-grade uninsulated terminals offer maximum versatility:

- Space-efficient design for compact installations

- Maximum conductor exposure for optimal connections

- Heat dissipation capability for high-current applications

- Universal compatibility with all terminal types

Perfect for: High-current applications, space-constrained panels, and custom installations requiring maximum flexibility.

TWIN CORD END TERMINALS

Specialized solutions for parallel conductor applications:

- Dual conductor accommodation in single terminal

- Balanced current distribution between conductors

- Space-saving installation for parallel connections

- Consistent crimping performance across both conductors

Ideal for: Parallel conductor runs, redundant systems, and high-current applications requiring multiple conductors.

SPECIALIZED CORD END TERMINALS

Application-specific terminals from innovative manufacturers:

| Terminal Type | Special Feature | Primary Application |

|---|---|---|

| Flag terminals | Extended tab for marking | Identification and testing |

| Extended barrel | Longer crimp area | Flexible wire applications |

| Stepped terminals | Multiple wire accommodation | Mixed gauge connections |

| Heat-shrink | Integrated insulation | Harsh environment protection |

FUTURE TRENDS IN CORD END TERMINAL TECHNOLOGY

Forward-thinking cord end terminal manufacturers are pioneering these emerging technologies:

ADVANCED MATERIALS SCIENCE

Next-generation cord end terminals incorporate:

- Enhanced copper alloys providing superior conductivity

- Eco-friendly insulation materials meeting environmental standards

- Corrosion-resistant platings extending operational life

- High-temperature polymers for extreme environment applications

MANUFACTURING AUTOMATION

Leading manufacturers are implementing:

- Automated quality inspection using machine vision systems

- Statistical process control ensuring consistent dimensions

- Robotic handling systems eliminating contamination

- Real-time testing integration providing immediate feedback

SMART IDENTIFICATION SYSTEMS

Innovation in product identification includes:

- QR code marking for traceability and documentation

- Color-coding standards for international compatibility

- Laser engraving options for permanent identification

- RFID integration for inventory management systems

ENVIRONMENTAL SUSTAINABILITY

Responsible manufacturers are pursuing:

- Recyclable material usage reducing environmental impact

- Energy-efficient production minimizing carbon footprint

- Waste reduction programs optimizing material utilization

- Sustainable packaging using biodegradable materials

HOW TO SELECT THE RIGHT CORD END TERMINALS FOR YOUR APPLICATION

When choosing products from cord end terminal manufacturers, match specifications to your specific requirements:

FOR INDUSTRIAL CONTROL SYSTEMS

Consider these critical factors:

| Selection Criteria | Recommendation | Reason |

|---|---|---|

| Wire gauge range | Complete coverage needed | System standardization |

| Color coding | Standard identification | Maintenance efficiency |

| Insulation material | PVC or nylon options | Environmental compatibility |

| Certification | UL/IEC compliance | Code requirements |

FOR HARSH ENVIRONMENTS

Industrial environments require enhanced protection:

- Temperature rating: Select appropriate range for ambient conditions

- Chemical resistance: Verify compatibility with present contaminants

- Moisture protection: Choose insulated versions for wet locations

- Vibration resistance: Ensure proper crimping for mechanical stress

FOR HIGH-CURRENT APPLICATIONS

Heavy-duty systems demand specialized considerations:

- Current capacity: Ensure adequate rating with safety margin

- Heat dissipation: Consider uninsulated options for thermal management

- Conductor material: Verify compatibility with copper or aluminum

- Connection integrity: Select manufacturers with proven crimp technology

FOR AUTOMATED MANUFACTURING

High-volume production requires specific features:

- Dimensional consistency: Critical for automated handling

- Packaging options: Bulk or tape-and-reel availability

- Quality certification: Statistical data for process control

- Supply reliability: Consistent availability for production scheduling

CORD END TERMINAL INSTALLATION BEST PRACTICES

PROPER CRIMPING TECHNIQUES

Essential steps for reliable connections:

- Select correct terminal size matching wire gauge exactly

- Strip wire to proper length matching terminal barrel depth

- Insert wire fully ensuring complete barrel engagement

- Use calibrated crimping tool with appropriate die set

- Verify crimp quality through visual and pull testing

Safety Warning: Always use properly calibrated crimping tools. Hand-operated pliers cannot provide adequate compression for reliable connections.

QUALITY VERIFICATION METHODS

Professional installation requires:

- Visual inspection checking for proper barrel deformation

- Pull testing verifying mechanical connection strength

- Electrical testing confirming continuity and resistance

- Documentation recording installation parameters for traceability

COMMON INSTALLATION MISTAKES

Avoid these frequent errors:

| Mistake | Consequence | Prevention |

|---|---|---|

| Wrong terminal size | Poor connection, overheating | Use wire gauge charts |

| Insufficient strip length | Inadequate contact area | Follow manufacturer specs |

| Over-crimping | Conductor damage | Use calibrated tools |

| Under-crimping | Loose connections | Verify crimp quality |

FREQUENTLY ASKED QUESTIONS ABOUT CORD END TERMINALS

What wire gauges require cord end terminals?

Cord end terminals are essential for stranded wire from 28 AWG to 4/0 AWG. While solid wire can connect directly to terminal blocks, stranded conductors require ferrules to prevent strand separation and ensure reliable connections. Most quality cord end terminal manufacturers provide complete coverage across this range.

Can I use different brands of cord end terminals in the same system?

While physically possible, mixing brands is not recommended for professional installations. Each manufacturer’s specifications may vary slightly, affecting crimp quality and connection reliability. Standardizing on products from a single cord end terminal supplier ensures consistent performance and simplifies inventory management.

How do I determine the correct crimping force for cord end terminals?

Proper crimping force depends on terminal size and crimping tool specifications. Reputable cord end terminal manufacturers provide detailed crimping specifications including force requirements, die dimensions, and quality verification procedures. Always use manufacturer-recommended crimping tools and calibration procedures.

What certifications should I look for when selecting cord end terminals?

Look for UL 486E, IEC 60947-7-4, and DIN 46228 certifications depending on your application requirements. These standards ensure products meet established safety and performance criteria. Cord end terminal manufacturers with these certifications demonstrate commitment to quality and regulatory compliance.

How often should crimping tools be calibrated?

Crimping tools should be calibrated at least annually or according to manufacturer recommendations. High-volume users may require more frequent calibration to maintain consistent crimp quality. Professional cord end terminal suppliers typically provide calibration services and guidance for their recommended tools.

Can cord end terminals be used in wet or outdoor applications?

Yes, with proper selection of insulated terminals rated for the environment. Choose terminals with appropriate IP ratings and chemical resistance for outdoor or wet applications. Leading cord end terminal manufacturers offer specialized products designed for harsh environmental conditions.

What’s the difference between Class 1 and Class 2 crimps?

Class 1 crimps provide higher mechanical strength through deeper barrel deformation, while Class 2 crimps offer easier tool design with adequate performance for most applications. The choice depends on application requirements and manufacturer specifications from your selected cord end terminal supplier.

Are there environmentally friendly cord end terminal options?

Yes, many manufacturers now offer RoHS-compliant and recyclable options. Progressive cord end terminal manufacturers are developing sustainable materials and production processes while maintaining electrical performance standards. Contact manufacturers directly for specific environmental compliance information.

PROFESSIONAL SELECTION GUIDE: MATCHING TERMINALS TO APPLICATIONS

INDUSTRIAL AUTOMATION SYSTEMS

Recommended specifications:

- Insulated terminals with color coding for wire identification

- DIN 46228 compliance for European equipment compatibility

- Temperature rating -40°C to +105°C for industrial environments

- UL recognition for North American installations

RENEWABLE ENERGY INSTALLATIONS

Critical requirements:

- High-temperature rating for solar panel applications

- UV-resistant insulation for outdoor exposure

- Corrosion-resistant plating for marine environments

- High-current capacity for power distribution systems

BUILDING MANAGEMENT SYSTEMS

Essential features:

- Color-coded identification for system organization

- Low-smoke materials for enclosed building spaces

- Standard wire gauge coverage for flexibility

- Bulk packaging options for large installations

AUTOMOTIVE AND TRANSPORTATION

Specialized needs:

- Vibration resistance for mobile applications

- Temperature cycling capability for engine compartments

- Sealed terminals for moisture protection

- Automotive-grade certifications for compliance

QUALITY ASSURANCE AND TESTING STANDARDS

MANUFACTURING QUALITY CONTROLS

Leading cord end terminal manufacturers implement comprehensive quality systems:

| Test Parameter | Standard | Frequency | Purpose |

|---|---|---|---|

| Dimensional verification | ±0.05mm tolerance | 100% inspection | Proper fit assurance |

| Electrical resistance | <0.5 milliohms | Statistical sampling | Connection quality |

| Pull-out force | Wire gauge specific | Batch testing | Mechanical integrity |

| Corrosion resistance | Salt spray testing | Product qualification | Longevity assurance |

COMPLIANCE CERTIFICATIONS

Essential certifications for professional applications:

- UL 486E: Underwriters Laboratories standard for wire connectors

- CSA C22.2 No. 65: Canadian electrical equipment standard

- IEC 60947-7-4: International standard for screw-type terminals

- DIN 46228: German standard for cord end terminals

- RoHS Directive: Restriction of hazardous substances compliance

TRACEABILITY REQUIREMENTS

Professional installations require:

- Batch identification for quality control tracking

- Manufacturing date codes for lifecycle management

- Material certifications for compliance documentation

- Test report availability for specification verification

COST OPTIMIZATION STRATEGIES

BULK PURCHASING CONSIDERATIONS

Maximize value through strategic procurement:

- Volume pricing tiers reducing unit costs significantly

- Standardized specifications simplifying inventory management

- Long-term supply agreements ensuring price stability

- Just-in-time delivery minimizing carrying costs

TOTAL COST OF OWNERSHIP

Consider all lifecycle costs:

| Cost Factor | Impact | Optimization Strategy |

|---|---|---|

| Initial purchase price | 30% of total cost | Volume negotiations |

| Installation labor | 40% of total cost | Efficient products/tools |

| Maintenance costs | 20% of total cost | Quality selection |

| Failure replacement | 10% of total cost | Reliable manufacturers |

VALUE ENGINEERING OPPORTUNITIES

Optimize specifications without compromising performance:

- Right-size terminals avoiding over-specification costs

- Standardize on fewer variants reducing inventory complexity

- Evaluate uninsulated options where appropriate for applications

- Consider regional suppliers for reduced shipping costs

CONCLUSION: CHOOSING THE RIGHT CORD END TERMINAL MANUFACTURER

Selecting the appropriate cord end terminal manufacturer for your electrical connection needs requires careful evaluation of technical specifications, quality certifications, and application requirements. The manufacturers highlighted in this guide represent industry leaders who consistently deliver exceptional performance and reliability.

Key selection criteria summary:

- Technical specifications matching your application requirements

- Quality certifications ensuring safety and performance standards

- Manufacturing capability supporting your volume and delivery needs

- Technical support providing application engineering assistance

- Total cost value optimizing lifecycle economics

Remember that reliable electrical connections form the foundation of safe, efficient industrial systems. By choosing high-quality cord end terminals from reputable manufacturers, you ensure optimal system performance while meeting all applicable codes and standards.

For expert assistance in selecting the ideal cord end terminal solution for your specific application requirements, contact Tonful Electric’s technical team at info@tonful.com. Our engineering experts provide comprehensive application support, helping you optimize connection reliability while achieving cost-effective solutions for your electrical systems.

About Tonful Electric: As a leading manufacturer of low-voltage electrical components, Tonful Electric specializes in precision-engineered cord end terminals and electrical connection solutions. Our commitment to quality, innovation, and customer service has established us as a trusted partner for industrial automation and electrical infrastructure projects worldwide.