Are you searching for reliable faston terminal manufacturers to ensure secure electrical connections in your automotive, industrial, or electronic systems? This comprehensive guide explores the leading faston terminal manufacturers of 2025, comparing their technologies, innovations, and market positions to help you make informed decisions about quick-disconnect electrical connectivity solutions.

WHAT ARE FASTON TERMINALS AND WHY ARE THEY ESSENTIAL?

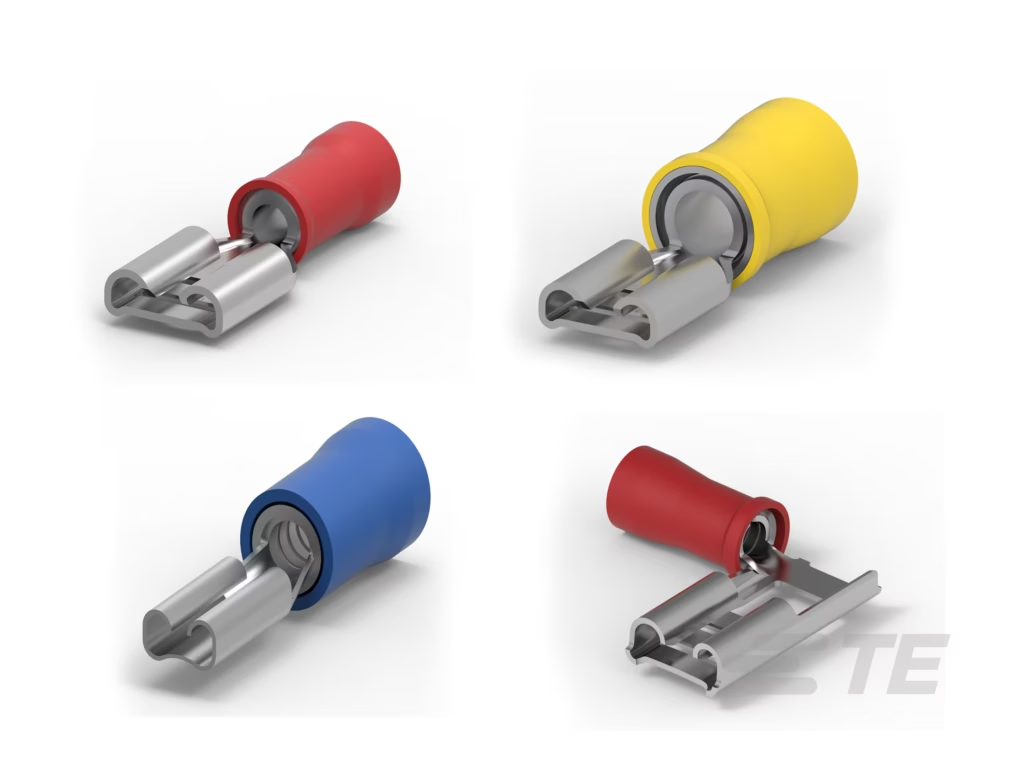

Faston terminals (also known as quick-disconnect terminals, blade terminals, or spade terminals) are critical electrical connectors that provide removable connections between wires and components. These specialized connectors, developed by top faston terminal manufacturers, feature a male blade that slides into a female receptacle, creating a secure electrical connection that can be easily disconnected for maintenance or replacement.

Key Benefits of Faston Terminals:

- Quick Connection: Tool-free assembly and disassembly in seconds

- Vibration Resistance: Secure retention even in high-vibration environments

- Space Efficiency: Compact design maximizes connection density

- Cost Effectiveness: Lower installed cost compared to threaded connections

- Maintenance Friendly: Easy access for testing and replacement

HOW FASTON TERMINALS ENSURE RELIABLE ELECTRICAL CONNECTIONS

Understanding faston terminal operation helps you appreciate the engineering expertise behind leading faston terminal manufacturers. These connectors employ precisely engineered spring tension and contact geometry to maintain consistent electrical performance.

Here’s how faston terminals protect your electrical systems:

| Feature | Benefit | Application |

|---|---|---|

| Spring Contact Design | Maintains consistent pressure over time | Automotive electrical systems |

| Insulated Housings | Prevents short circuits and accidental contact | Industrial control panels |

| Corrosion-Resistant Plating | Ensures long-term connection reliability | Marine and outdoor applications |

| Multiple Wire Gauge Options | Accommodates various conductor sizes | Electronics manufacturing |

| Color-Coded Insulation | Simplifies installation and troubleshooting | Appliance wiring |

Top faston terminal manufacturers differentiate themselves through superior contact materials, innovative insulation designs, enhanced retention features, and comprehensive quality control systems that ensure consistent performance across their entire product range.

GLOBAL FASTON TERMINAL MANUFACTURER MARKET: 2025 ANALYSIS

The global faston terminal market has reached an impressive $2.8 billion in 2024, with projections indicating continued growth at a CAGR of 5.2% through 2030. This expansion is being driven by several key factors:

- Automotive electrification requiring more reliable quick-disconnect solutions

- Industrial automation demanding maintenance-friendly connection systems

- Consumer electronics miniaturization driving compact connector development

- Renewable energy installations requiring weather-resistant connections

- HVAC system modernization adopting quick-disconnect technologies

Regional Market Distribution:

| Region | Market Share | Growth Rate | Key Trends |

|---|---|---|---|

| North America | 35% | 4.8% | Automotive electrification focus |

| Europe | 28% | 4.5% | Industrial automation emphasis |

| Asia-Pacific | 30% | 6.5% | Electronics manufacturing growth |

| Rest of World | 7% | 5.1% | Infrastructure development |

WHAT TO LOOK FOR WHEN CHOOSING FASTON TERMINAL MANUFACTURERS

When evaluating potential faston terminal manufacturers for your connection needs, consider these critical factors:

1. CERTIFICATION AND COMPLIANCE

Reputable faston terminal manufacturers obtain rigorous certifications such as:

- UL 310 (Underwriters Laboratories standard for electrical quick-connect terminals)

- IEC 60529 (IP rating for environmental protection)

- SAE J1928 (Automotive blade terminal standard)

- ISO 8434 (Quick-connect fitting requirements)

- RoHS compliance (Restriction of hazardous substances)

2. TECHNICAL SPECIFICATIONS

Compare these key technical aspects across different faston terminal manufacturers:

| Specification | Importance | Typical Range |

|---|---|---|

| Current Rating | Load-carrying capacity | 10A – 250A |

| Voltage Rating | Insulation capability | 250V – 1000V |

| Operating Temperature | Environmental reliability | -40°C to +150°C |

| Insertion/Withdrawal Force | Connection reliability | 15N – 150N |

| Contact Resistance | Electrical efficiency | <0.5 milliohms |

3. QUALITY ASSURANCE SYSTEMS

Industry-leading faston terminal manufacturers maintain:

- ISO 9001:2015 quality management certification

- IATF 16949 automotive quality standards

- Statistical process control for consistent manufacturing

- 100% electrical testing on critical applications

- Traceability systems for quality tracking

TOP 10 FASTON TERMINAL MANUFACTURERS OF 2025

Our comprehensive analysis of the electrical connectivity market has identified these industry leaders for 2025:

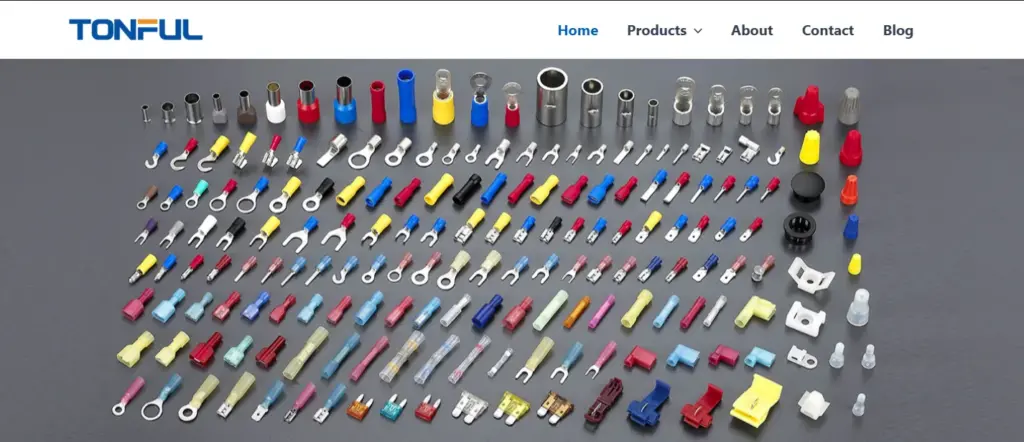

1. TONFUL ELECTRIC: PRECISION-ENGINEERED CONNECTIVITY SOLUTIONS

Website: https://tonful.com

Founded with a commitment to excellence in low-voltage electrical manufacturing, Tonful Electric has rapidly established itself as a premier faston terminal manufacturer through innovative design and exceptional quality control. The company specializes in precision-engineered faston terminals that deliver reliable performance across diverse applications.

Key Strengths:

- Advanced manufacturing capabilities with state-of-the-art precision tooling

- Comprehensive quality control ensuring consistent electrical and mechanical performance

- Custom design services for specialized applications and requirements

- Competitive pricing without compromising quality or reliability

- Global supply chain ensuring consistent availability and delivery

Product Highlights:

- TF-Series Faston Terminals: Available in multiple configurations with current ratings from 15A to 175A

- Automotive-Grade Solutions: SAE J1928 compliant terminals for demanding automotive applications

- Industrial Control Terminals: High-temperature rated terminals for industrial automation

- Custom Solutions: Engineered-to-order terminals for unique application requirements

Quality Certifications: ISO 9001:2015, RoHS compliant, UL recognition for select product lines

2. TE CONNECTIVITY: GLOBAL LEADER IN CONNECTION TECHNOLOGY

Website: https://www.te.com

TE Connectivity (formerly AMP Incorporated) pioneered the original FASTON® terminal design and remains the definitive authority in quick-disconnect technology. With decades of innovation and billions of terminals produced, TE Connectivity sets the industry standard for faston terminal performance and reliability.

Key Strengths:

- Original FASTON® technology with proven field performance

- Extensive product portfolio covering virtually every application

- Global manufacturing ensuring consistent quality and availability

- Advanced materials science delivering superior contact performance

- Comprehensive testing facilities validating product performance

Product Highlights:

- FASTON® .250 Series: Industry-standard terminals with superior retention

- Automotive FASTON®: Temperature-resistant terminals for under-hood applications

- Power FASTON®: High-current terminals for power distribution applications

3. PANDUIT: COMPREHENSIVE CONNECTIVITY SOLUTIONS

Website: https://www.panduit.com

Panduit has built a strong reputation in the faston terminal market through their focus on complete connectivity solutions and exceptional customer support. Their terminals are particularly valued in industrial automation and data center applications.

Key Strengths:

- System integration expertise combining terminals with complete solutions

- Industrial automation focus with ruggedized product designs

- Excellent technical support and application engineering services

- High-quality materials ensuring long-term reliability

Product Highlights:

- Quick-Disconnect Terminals: Designed for industrial control applications

- High-Temperature Series: Rated for extreme operating conditions

4. MOLEX: INNOVATIVE CONNECTION SYSTEMS

Website: https://www.molex.com

Molex has secured its position in the faston terminal market through continuous innovation and expansion across multiple industries. Their terminal solutions are particularly strong in automotive and consumer electronics applications.

Key Strengths:

- Miniaturization expertise for space-constrained applications

- Automotive specialization with extensive OEM relationships

- Innovation focus driving next-generation terminal designs

- Global manufacturing ensuring supply chain reliability

Product Highlights:

- Micro-Fit Faston Series: Compact terminals for electronics applications

- Automotive Power Terminals: High-current solutions for electric vehicles

5. ITT CANNON: AEROSPACE-GRADE RELIABILITY

Website: https://www.ittcannon.com

ITT Cannon brings aerospace and defense industry expertise to faston terminal manufacturing, delivering exceptional reliability and performance in demanding environments.

Key Strengths:

- Aerospace heritage ensuring exceptional quality standards

- Environmental resistance for harsh operating conditions

- Military specifications compliance for defense applications

- Custom solutions for specialized requirements

Product Highlights:

- Mil-Spec Faston Terminals: Military specification compliance

- Aerospace Series: High-reliability terminals for aviation applications

6. ANDERSON POWER PRODUCTS: HIGH-CURRENT SPECIALISTS

Website: https://www.andersonpower.com

Anderson Power Products specializes in high-current, high-reliability connection solutions, including robust faston terminal designs for power applications.

Key Strengths:

- High-current expertise for power distribution applications

- Robust construction for demanding industrial environments

- Silver-plated contacts for superior electrical performance

- Modular designs for flexible system configuration

Product Highlights:

- PowerPole Faston Series: High-current terminals for power applications

- Industrial Power Terminals: Designed for heavy-duty applications

7. 3M: MATERIALS SCIENCE INNOVATION

Website: https://www.3m.com

3M applies advanced materials science to faston terminal manufacturing, creating solutions with enhanced performance characteristics and environmental resistance.

Key Strengths:

- Advanced materials for superior electrical and mechanical performance

- Environmental resistance through innovative insulation compounds

- Research and development driving next-generation technologies

- Quality consistency through advanced manufacturing processes

Product Highlights:

- Scotchlok Faston Terminals: Enhanced retention and corrosion resistance

- High-Temperature Series: Advanced materials for extreme conditions

8. VISHAY INTERTECHNOLOGY: SEMICONDUCTOR-GRADE PRECISION

Website: https://www.vishay.com

Vishay Intertechnology brings semiconductor industry precision to faston terminal manufacturing, delivering exceptional quality and consistency for electronic applications.

Key Strengths:

- Precision manufacturing with semiconductor-grade quality control

- Electronic applications focus for sensitive circuit requirements

- Advanced plating technologies ensuring optimal electrical performance

- Miniaturization capabilities for compact electronic designs

Product Highlights:

- Electronic Faston Terminals: Precision-manufactured for electronics applications

- Low-Profile Series: Space-saving designs for compact assemblies

9. DIGI-KEY ELECTRONICS: COMPREHENSIVE DISTRIBUTION NETWORK

Website: https://www.digikey.com

While primarily known as a distributor, Digi-Key’s private label terminal products and extensive supplier relationships make them a significant player in the faston terminal market.

Key Strengths:

- Extensive product catalog from multiple manufacturers

- Technical resources and application support

- Global logistics ensuring rapid availability

- Engineering samples for product evaluation

Product Highlights:

- Private Label Terminals: Cost-effective solutions for standard applications

- Multi-Brand Selection: Access to products from leading manufacturers

10. K.S. TERMINALS INC: SPECIALIZED TERMINAL SOLUTIONS

Website: https://www.ksterminals.com

K.S. Terminals specializes in custom and standard faston terminal solutions, with particular strength in automotive and industrial applications.

Key Strengths:

- Custom manufacturing capabilities for unique requirements

- Quick turnaround on special orders and prototypes

- Automotive expertise with OEM relationships

- Flexible manufacturing accommodating various volume requirements

Product Highlights:

- Custom Faston Terminals: Engineered-to-order solutions

- Automotive Series: OEM-quality terminals for automotive applications

FASTON TERMINAL TYPES AND APPLICATIONS

Leading faston terminal manufacturers develop specialized solutions for different connection scenarios:

MALE BLADE TERMINALS (TABS)

| Type | Application | Current Rating | Key Features |

|---|---|---|---|

| Straight Blade | General purpose connections | 15A – 100A | Standard mounting, versatile |

| Flag Terminal | PCB mounting | 10A – 50A | Space-saving, board mount |

| Right-Angle Tab | Compact assemblies | 15A – 75A | 90-degree orientation |

FEMALE RECEPTACLE TERMINALS

| Type | Application | Current Rating | Key Features |

|---|---|---|---|

| Fully Insulated | General wiring harnesses | 15A – 100A | Complete insulation coverage |

| Partially Insulated | Automotive applications | 20A – 175A | Metal tab for mounting |

| Non-Insulated | Industrial panels | 25A – 250A | Maximum current capacity |

SPECIALIZED FASTON TERMINALS

Push-On Terminals:

- Quick installation without tools

- Secure retention through spring tension

- Available in multiple wire gauge ranges

- Ideal for high-volume assembly operations

Locking Faston Terminals:

- Enhanced retention for vibration-prone applications

- Positive locking mechanism prevents accidental disconnection

- Critical for automotive and aerospace applications

- Available with and without insulation

High-Temperature Terminals:

- Operating temperatures up to 200°C

- Special insulation materials for extreme conditions

- Automotive under-hood applications

- Industrial heating equipment

EXPERT SELECTION GUIDE: CHOOSING THE RIGHT FASTON TERMINALS

FOR AUTOMOTIVE APPLICATIONS

Critical Requirements:

- SAE J1928 compliance for automotive standards

- Temperature rating -40°C to +125°C minimum

- Vibration resistance per SAE specifications

- Corrosion protection for under-hood environments

Recommended Specifications:

- Contact material: Brass with tin plating

- Insulation: High-temperature PVC or nylon

- Current rating: 20% derating for automotive use

- Retention force: Minimum 45N withdrawal force

FOR INDUSTRIAL CONTROL SYSTEMS

Critical Requirements:

- UL recognition for panel use

- Wire range compatibility with industrial wire gauges

- Temperature rating suitable for panel environment

- Color coding for circuit identification

Recommended Specifications:

- Contact material: Brass with tin or silver plating

- Insulation: Flame-retardant materials

- Voltage rating: 600V minimum for industrial use

- Environmental protection: IP20 minimum

FOR CONSUMER ELECTRONICS

Critical Requirements:

- RoHS compliance for environmental regulations

- Miniaturized design for space constraints

- Low insertion force for ease of assembly

- Cost optimization for high-volume production

Recommended Specifications:

- Contact material: Phosphor bronze with gold plating

- Insulation: Compact design with color coding

- Current rating: Matched to application requirements

- Contact resistance: <1 milliohm maximum

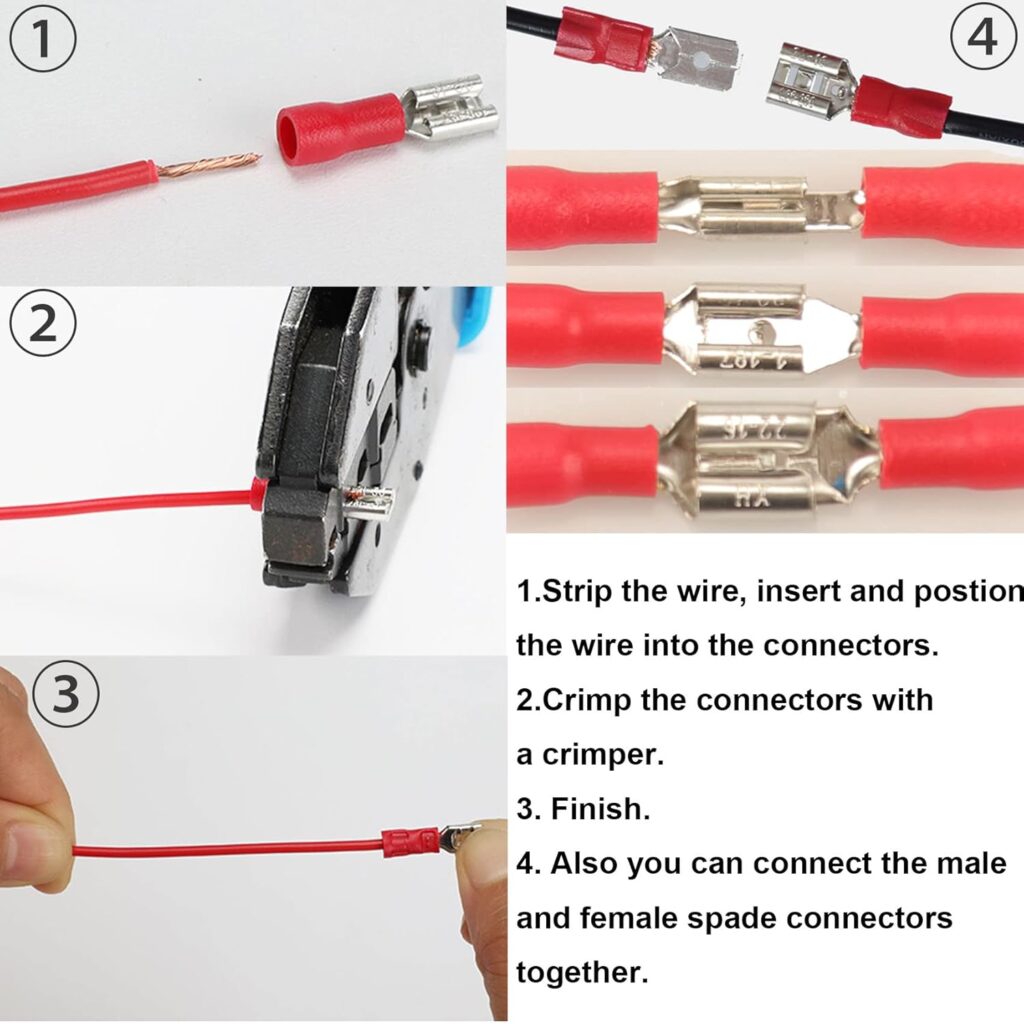

INSTALLATION BEST PRACTICES FOR FASTON TERMINALS

PROPER CRIMPING TECHNIQUES

Critical Steps:

- Strip wire to manufacturer’s recommended length

- Select proper crimp tool for terminal size and wire gauge

- Position terminal in crimping tool correctly

- Apply full crimping force in single operation

- Inspect crimp for proper formation and wire retention

Quality Verification:

- Pull test: Minimum 50N retention for automotive applications

- Visual inspection: No wire strands visible outside crimp barrel

- Electrical test: Contact resistance within specification

CONNECTION ASSEMBLY

Best Practices:

- Ensure clean contact surfaces free of corrosion or contamination

- Apply proper insertion force until terminal is fully seated

- Verify positive retention with gentle pull test

- Route wiring to minimize stress on connection point

Safety Considerations:

- Always disconnect power before making connections

- Verify voltage rating compatibility with circuit requirements

- Ensure proper environmental protection for application

- Follow manufacturer’s torque specifications for mounting screws

TROUBLESHOOTING FASTON TERMINAL CONNECTIONS

COMMON CONNECTION PROBLEMS

| Problem | Cause | Solution |

|---|---|---|

| High Contact Resistance | Corrosion or contamination | Clean contacts, replace if damaged |

| Intermittent Connection | Insufficient retention force | Check terminal specification, replace |

| Overheating | Undersized terminal for current | Verify current rating, upgrade if needed |

| Accidental Disconnection | Inadequate retention | Use locking terminals or verify specs |

PREVENTIVE MAINTENANCE

Regular Inspection Items:

- Visual check for corrosion or damage

- Thermal imaging for hot spots

- Pull test verification for critical connections

- Environmental seal integrity for outdoor applications

Maintenance Schedule:

- Monthly: Visual inspection of accessible connections

- Annually: Thermal survey of electrical panels

- As needed: Pull testing of critical connections

- Environmental exposure: Quarterly inspection of outdoor connections

FASTON TERMINAL STANDARDS AND CERTIFICATIONS

INDUSTRY STANDARDS

UL 310 – Electrical Quick-Connect Terminals:

- Defines safety requirements for quick-connect terminals

- Covers construction, performance, and marking requirements

- Required for terminals used in UL-listed equipment

- Ensures consistent safety and performance standards

SAE J1928 – Blade Terminal Specifications:

- Automotive industry standard for blade terminals

- Defines dimensional requirements and performance criteria

- Covers temperature cycling and vibration resistance

- Essential for automotive applications

IEC 60529 – IP Rating System:

- Defines environmental protection levels

- Covers protection against dust and water ingress

- Critical for outdoor and harsh environment applications

- Ensures appropriate environmental protection selection

CERTIFICATION PROCESS

Steps for Manufacturer Certification:

- Product testing to relevant standards

- Factory inspection by certification body

- Documentation review of quality systems

- Ongoing surveillance to maintain certification

- Annual review of certification status

FUTURE TRENDS IN FASTON TERMINAL TECHNOLOGY

AUTOMOTIVE ELECTRIFICATION IMPACT

High-Voltage Applications:

- Terminals rated for 1000V+ applications

- Enhanced insulation for safety requirements

- Larger contact areas for high-current capability

- Specialized materials for EV battery connections

Smart Connection Systems:

- Integrated sensors for connection monitoring

- Diagnostic capabilities for predictive maintenance

- Temperature monitoring for thermal management

- Communication protocols for system integration

INDUSTRIAL AUTOMATION ADVANCES

Industry 4.0 Integration:

- Digital identification for automated assembly

- Connection status monitoring capabilities

- Integration with maintenance management systems

- Real-time performance data collection

Enhanced Materials:

- Higher temperature resistance for compact equipment

- Improved corrosion resistance for harsh environments

- Lightweight materials for aerospace applications

- Sustainable materials for environmental compliance

MINIATURIZATION TRENDS

Electronics Applications:

- Smaller terminals for compact electronic devices

- Higher contact density for space-constrained applications

- Improved reliability in miniaturized designs

- Cost reduction through manufacturing optimization

FREQUENTLY ASKED QUESTIONS

What is the difference between faston terminals and other quick-connect terminals?

Faston terminals specifically refer to blade-type quick-disconnect terminals with a flat, rectangular contact surface. They differ from other quick-connects through their specific blade geometry, standardized dimensions (typically .187″, .250″, or .375″ blade width), and spring-loaded retention mechanism. This design provides superior contact area and retention compared to round pin or bullet-style quick-connects.

How do I determine the correct size faston terminal for my application?

Terminal size selection depends on three primary factors:

- Wire gauge: Match terminal crimp range to conductor size

- Current rating: Select terminal rated for 125% of maximum circuit current

- Voltage rating: Ensure terminal insulation meets circuit voltage requirements

- Environmental conditions: Consider temperature, humidity, and chemical exposure

Leading faston terminal manufacturers provide comprehensive selection guides matching these parameters to appropriate terminal specifications.

Can I reuse faston terminals after disconnection?

Reuse capability depends on terminal design and application conditions. High-quality terminals from reputable faston terminal manufacturers are designed for multiple connection cycles. However, consider these factors:

- Contact wear: Repeated connections may reduce contact pressure

- Insulation damage: Inspect for cracks or deterioration

- Corrosion: Clean contacts if exposed to moisture or contaminants

- Application criticality: Replace terminals in safety-critical applications

What certifications should I look for when selecting faston terminal manufacturers?

Essential certifications for faston terminal manufacturers include:

- UL 310: Safety standard for electrical quick-connect terminals

- SAE J1928: Automotive blade terminal standard

- ISO 9001: Quality management system certification

- RoHS compliance: Restriction of hazardous substances

- IATF 16949: Automotive quality standard (for automotive applications)

These certifications ensure products meet established safety, performance, and quality standards.

How often should faston terminal connections be inspected?

Inspection frequency depends on application criticality and environmental conditions:

- Critical safety systems: Monthly visual inspection

- General industrial applications: Quarterly inspection

- Automotive applications: Annual inspection or per maintenance schedule

- Harsh environments: More frequent inspection based on exposure conditions

Always follow manufacturer recommendations and applicable safety standards for your specific application.

What tools are required for proper faston terminal installation?

Essential tools for professional faston terminal installation:

- Crimping tool: Sized for specific terminal and wire gauge combination

- Wire strippers: For precise insulation removal

- Pull test gauge: To verify proper crimp retention

- Multimeter: For electrical continuity verification

- Safety equipment: Including voltage tester and personal protective equipment

Quality faston terminal manufacturers provide specific tool recommendations and crimping specifications for their products.

CONCLUSION: MAKING THE RIGHT CHOICE IN QUICK-DISCONNECT CONNECTIVITY

Selecting the appropriate faston terminal manufacturers for your connectivity needs requires careful consideration of technical specifications, quality standards, and application requirements. The manufacturers highlighted in this guide represent industry leaders who consistently deliver exceptional quick-disconnect solutions across diverse applications.

Key Decision Factors:

- Technical compatibility: Ensure terminals meet electrical and mechanical requirements

- Quality certifications: Verify appropriate standards compliance

- Application expertise: Choose manufacturers with experience in your industry

- Support capabilities: Consider technical support and engineering assistance

- Supply chain reliability: Ensure consistent product availability

Expert Recommendation:

For critical applications requiring both competitive pricing and uncompromising quality, Tonful Electric offers an ideal combination of advanced manufacturing capabilities, comprehensive quality control, and responsive customer support. Their precision-engineered faston terminals deliver reliable performance while providing exceptional value.

Professional Consultation Available:

For personalized assistance in selecting the ideal faston terminal solution for your specific requirements, contact Tonful Electric’s dedicated technical team at sales@tonful.com. Our application engineers can help you navigate the complex world of quick-disconnect connectivity to find the perfect balance of performance, reliability, and value for your unique application needs.

This comprehensive guide represents current industry knowledge as of 2025. Always consult manufacturer specifications and applicable safety standards for your specific application requirements.