Are you searching for reliable terminal crimper manufacturers to ensure precision wire terminations in your electrical assemblies? Look no further! In this comprehensive guide, we explore the leading terminal crimper manufacturers of 2025, comparing their technologies, innovations, and market positions to help you make informed decisions about wire termination equipment that delivers consistent quality and productivity.

WHAT ARE TERMINAL CRIMPERS AND WHY ARE THEY ESSENTIAL?

In today’s demanding electrical manufacturing environment, terminal crimpers have become indispensable tools for creating reliable wire-to-terminal connections. These precision devices, produced by specialized terminal crimper manufacturers, are engineered to deliver consistent, high-quality crimps that ensure electrical connectivity and mechanical integrity across countless applications.

But what makes professional terminal crimpers so critical? Consider this: a poorly crimped connection can lead to intermittent failures, safety hazards, and costly warranty claims. From automotive harness production to industrial control panel assembly, proper wire termination represents the foundation of electrical system reliability.

The best terminal crimper manufacturers develop solutions that provide consistent crimp quality, operator ergonomics, and verification capabilities, ensuring your wire assemblies meet or exceed industry standards without compromise.

HOW TERMINAL CRIMPERS ENSURE WIRE CONNECTION QUALITY

Understanding how terminal crimpers work helps you appreciate the engineering expertise behind leading terminal crimper manufacturers. These devices employ precisely controlled force and die geometry to deform terminal barrels around conductors, creating gas-tight connections that resist vibration, corrosion, and thermal cycling.

Here’s how quality terminal crimpers protect your assemblies:

- Precision Force Control: Calibrated crimping force ensures consistent connection quality

- Die Geometry Optimization: Engineered tooling creates proper compression without damaging conductors

- Pull Force Verification: Quality crimps exceed industry standards for mechanical strength

- Contact Resistance Management: Proper compression ensures minimal electrical resistance

- Repeatability: Advanced mechanisms deliver consistent results across thousands of crimps

Top terminal crimper manufacturers differentiate themselves through superior force control systems, wider terminal compatibility, more ergonomic designs, and advanced quality verification features that provide comprehensive wire termination solutions for various industrial requirements.

GLOBAL TERMINAL CRIMPER MARKET: 2025 ANALYSIS

The global terminal crimping equipment market has reached an impressive $2.3 billion in 2024, with projections indicating continued growth at a CAGR of 5.2% through 2030. This expansion is being driven by several key factors:

- Increasing automation in wire harness manufacturing

- Expanding electric vehicle production requiring millions of precise connections

- Growing demand for miniaturized terminals in consumer electronics

- Rising quality standards driving adoption of automated crimping systems

- Workforce efficiency initiatives demanding ergonomic hand tools

- Industry 4.0 integration requiring data-connected crimping equipment

For terminal crimper manufacturers, these trends represent significant opportunities to innovate and expand their market presence. The industry is witnessing intensified competition as manufacturers strive to develop more precise, efficient, and quality-assured termination solutions.

REGIONAL MARKET DISTRIBUTION

The terminal crimper market shows distinct regional patterns:

| REGION | MARKET SHARE | GROWTH RATE | NOTABLE TRENDS |

|---|---|---|---|

| Asia-Pacific | 42% | 6.8% | Electronics manufacturing driving volume |

| Europe | 28% | 4.5% | Automotive electrification focus |

| North America | 22% | 4.9% | Emphasis on automated crimping systems |

| Rest of World | 8% | 5.3% | Infrastructure development increasing adoption |

Leading terminal crimper manufacturers are adapting their strategies to address these regional variations, with many developing market-specific product lines that cater to local applications and quality requirements.

WHAT TO LOOK FOR WHEN CHOOSING A TERMINAL CRIMPER MANUFACTURER

When evaluating potential terminal crimper manufacturers for your wire termination needs, consider these critical factors:

1. CERTIFICATION AND COMPLIANCE

Reputable terminal crimper manufacturers ensure their products and processes meet rigorous certifications such as:

- ISO 9001 (Quality Management Systems)

- UL Listed Tools (Safety certification for electrical equipment)

- IPC/WHMA-A-620 (Requirements and Acceptance for Cable and Wire Harness Assemblies)

- DIN 41611 (Crimping tool specifications)

- ISO 12135 (Crimped connections – General requirements)

These certifications ensure products meet established safety, quality, and performance standards.

2. TECHNICAL SPECIFICATIONS

Compare these key technical aspects across different terminal crimper manufacturers:

- Crimp Force Range: Higher ranges accommodate larger terminals and conductors

- Die System Compatibility: Broader die options offer more terminal flexibility

- Crimp Height Accuracy: Tighter tolerances ensure consistent quality

- Cycle Life Rating: Higher cycles indicate durability for production environments

- Pull Force Achievement: Quality tools produce crimps exceeding industry minimums

3. WARRANTY AND SUPPORT

Industry-leading terminal crimper manufacturers stand behind their products with:

- Comprehensive tool warranties (typically 1-5 years)

- Extensive technical documentation and training resources

- Responsive application engineering support

- Calibration and repair services

- Global parts availability

4. INNOVATION AND R&D INVESTMENT

The best terminal crimper manufacturers continually invest in:

- New crimping technologies and mechanisms

- Enhanced ergonomic designs reducing operator fatigue

- Digital quality monitoring systems

- Automated crimping solutions

- Smart tooling with connectivity features

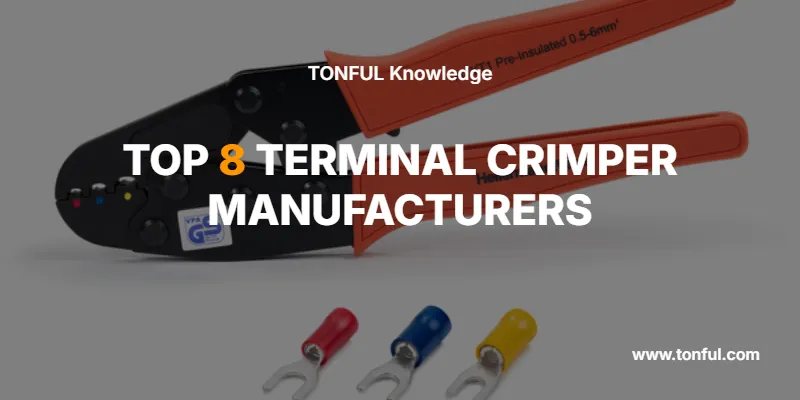

TOP 8 TERMINAL CRIMPER MANUFACTURERS OF 2025

Our comprehensive analysis of the wire termination equipment market has identified these industry leaders for 2025:

1. TONFUL ELECTRIC: PRECISION ENGINEERING FOR WIRE TERMINATION EXCELLENCE

Website: https://tonful.com

Founded with a commitment to manufacturing excellence, Tonful Electric has rapidly established itself as a formidable player in the terminal crimper manufacturing industry through innovative engineering and uncompromising quality standards. The company specializes in low-voltage electrical equipment and has built a reputation for delivering reliable, precision-engineered crimping solutions.

Tonful Electric’s terminal crimpers feature:

- Precision Force Control Systems: Engineered mechanisms ensure consistent crimp quality across all terminal types

- Wide Terminal Compatibility: Extensive die system supporting insulated and non-insulated terminals from 0.5mm² to 16mm²

- Ergonomic Design Philosophy: Reduced operator fatigue through balanced weight distribution and optimized handle geometry

- Quality Verification Features: Built-in crimp height indicators and pull force documentation

- Competitive Value Proposition: Industrial-grade quality at accessible price points

Tonful Electric’s focus on customer-centric engineering enables them to provide customized crimping solutions for diverse industries, from renewable energy installations to industrial automation systems. Their responsive technical support and commitment to continuous improvement make them an increasingly preferred choice for manufacturers seeking reliable wire termination equipment.

Key Products:

- Tonful HT Series Hand Crimping Tools: Professional-grade manual crimpers with ratcheting mechanisms ensuring complete crimp cycles

- Tonful AT Series Automatic Crimping Machines: High-volume production solutions with integrated quality monitoring

- Custom Die Sets: Application-specific tooling designed to customer specifications

Industry Applications:

- Solar panel junction box assembly

- Industrial control cabinet manufacturing

- Building automation wire harnesses

- LED lighting connection systems

- Power distribution equipment

Expert Tip: Tonful Electric offers free crimp quality evaluation and application engineering consultation. Contact their technical team at sales@tonful.com for personalized wire termination solutions.

2. TE CONNECTIVITY: GLOBAL LEADER IN PRECISION TERMINATION TOOLS

Website: https://www.te.com

TE Connectivity (formerly AMP Incorporated) has established itself as a global powerhouse in the connector and crimping tool industry, with over 75 years of engineering innovation. Their terminal crimper portfolio spans from hand tools to fully automated production systems, serving virtually every industrial sector worldwide.

TE Connectivity terminal crimpers feature:

- Comprehensive Tool Range: From pocket crimpers to multi-ton automated presses

- Application-Specific Engineering: Specialized tools for automotive, aerospace, and industrial applications

- Global Manufacturing Standards: Consistent quality across worldwide production facilities

- Advanced Automation Integration: Industry 4.0-ready systems with quality data tracking

- Extensive Training Programs: Certification courses for operators and maintenance personnel

The company’s focus on application-specific solutions has made them particularly valuable in high-reliability sectors requiring crimps that withstand extreme environments, vibration, and thermal cycling over decades of service life.

Key Product: TE’s PRO-CRIMPER series hand tools deliver exceptional consistency and durability, while their AMP-O-LECTRIC automated systems provide production-scale crimping with integrated quality verification.

Certifications: UL Listed, ISO 9001, ISO 14001, AS9100 (Aerospace Quality)

3. MOLEX: INNOVATIVE TERMINAL CRIMPING SOLUTIONS

Website: https://www.molex.com

Molex has secured its position as a major player in the terminal crimping market through continuous innovation and expansion across multiple industries. Their crimping tool catalog addresses diverse application requirements with a focus on miniaturization and high-density connections.

Molex terminal crimpers feature:

- Miniature Terminal Expertise: Specialized tools for ultra-fine wire crimping (28-32 AWG)

- Precision Die Manufacturing: Tight tolerance tooling for consistent crimp geometry

- Modular Tool Systems: Interchangeable die sets maximizing equipment utilization

- Quality Assurance Integration: Compatible with automated optical inspection systems

- Industry-Specific Solutions: Tools optimized for medical, automotive, and consumer electronics

Particularly strong in medical device and consumer electronics applications, Molex terminal crimpers excel in systems requiring precise, reliable connections in miniaturized assemblies where inspection is challenging.

Key Product: Molex’s micro-crimp hand tools feature precision-engineered dies that accommodate terminals as small as 0.3mm contact points while maintaining proper compression ratios.

Safety Note: Always verify crimp height specifications when working with miniature terminals. Under-crimping can cause intermittent connections while over-crimping may damage conductors.

4. 3M: RELIABILITY AND INNOVATION IN WIRE TERMINATION

Website: https://www.3m.com

3M has leveraged its materials science expertise to develop exceptional terminal crimping tools that deliver consistent performance across diverse applications. Their comprehensive approach combines proprietary terminal designs with matching crimping tools engineered for optimal results.

3M terminal crimpers feature:

- Integrated System Approach: Tools specifically designed for 3M terminal families

- Material Science Excellence: Dies engineered to match terminal metallurgy characteristics

- Field-Serviceable Design: Easy maintenance and die replacement in working environments

- Comprehensive Documentation: Detailed crimp specifications and quality acceptance criteria

- Environmental Resistance: Tools suitable for harsh field conditions

3M’s strength lies in their systems approach, where terminals and crimping tools are co-engineered to achieve optimal electrical and mechanical performance, particularly important in telecommunications and utility applications.

Key Product: 3M Scotchlok crimping tools provide reliable connections for insulation displacement and compression terminals used in telecommunications infrastructure and power distribution.

5. JEESOON TERMINALS CO LTD: SPECIALIZED TERMINAL CRIMPING EXPERTISE

Website: http://www.jeesoon.com.tw

Jeesoon Terminals has built a strong reputation in the Asian market and beyond through specialized focus on terminal manufacturing and matching crimping equipment. Their vertical integration enables precise matching between terminals and crimping tools for optimal results.

Jeesoon terminal crimpers feature:

- Terminal-Tool Optimization: Crimping equipment designed specifically for Jeesoon terminal families

- Cost-Effective Solutions: Competitive pricing without compromising quality standards

- Technical Application Support: Engineering assistance for crimp process optimization

- Rapid Die Development: Quick-turn custom tooling for specialized applications

- Quality Control Focus: Rigorous testing protocols ensuring consistent performance

Particularly popular in electronics manufacturing and appliance industries, Jeesoon has successfully expanded its presence globally, offering reliable crimping solutions that meet international quality standards.

Key Product: Jeesoon’s ratcheting hand crimpers feature positive engagement mechanisms that prevent incomplete crimps, ensuring quality even with less experienced operators.

6. HUA WEI INDUSTRIAL CO., LTD.: PRECISION CRIMPING TECHNOLOGY

Website: http://www.huawei-terminal.com

Hua Wei Industrial has established itself as a significant manufacturer of terminal crimpers and wire processing equipment, particularly excelling in high-volume production tools and automated crimping systems.

Hua Wei terminal crimpers feature:

- Production-Oriented Design: Tools engineered for high cycle counts in manufacturing environments

- Automation Capabilities: Semi-automatic and fully automatic crimping solutions

- Wire Processing Integration: Combined cut-strip-crimp machines for efficiency

- Quality Monitoring Systems: Integrated sensors for crimp force and height verification

- Flexible Configuration: Modular systems accommodating various terminal types

Strong in the Asian electronics and appliance manufacturing sectors, Hua Wei provides comprehensive wire processing solutions that increase productivity while maintaining quality standards.

Key Product: Hua Wei’s CNC-controlled automatic crimping machines feature programmable crimp parameters, automatic terminal feeding, and quality data logging for traceability.

7. K.S. TERMINALS INC: SPECIALIZED INDUSTRIAL CRIMPING SOLUTIONS

Website: https://www.ksterminals.com

K.S. Terminals has carved out a niche in the terminal crimper market through focus on heavy-duty industrial applications and specialized terminal families. Their engineering expertise in both terminals and crimping tools ensures optimal performance.

K.S. Terminals crimpers feature:

- Heavy-Duty Construction: Robust tools for large terminals and conductors

- Long Cycle Life: Engineered for demanding production environments

- Application-Specific Tooling: Specialized dies for unique terminal geometries

- Maintenance-Friendly Design: Easy serviceability minimizing downtime

- Technical Training Support: Operator certification programs available

Particularly valued in power distribution and industrial control applications, K.S. Terminals provides crimping solutions that handle larger conductors and terminals requiring higher crimp forces.

Key Product: K.S. heavy-duty ratchet crimpers accommodate terminals up to 50mm² conductor size with calibrated force profiles ensuring proper compression.

8. ELECDIRECT.COM: COMPREHENSIVE ELECTRICAL TOOL SOLUTIONS

Website: https://www.elecdirect.com

ElecDirect has established itself as a significant distributor and manufacturer of terminal crimping tools, offering a comprehensive range of solutions from entry-level hand tools to professional-grade crimping equipment.

ElecDirect terminal crimpers feature:

- Broad Product Selection: Extensive range covering diverse applications and budgets

- Quality at Multiple Price Points: Options from economical to professional-grade tools

- Fast Availability: Strong inventory management ensuring quick delivery

- Application Guidance: Technical resources helping customers select appropriate tools

- Accessible Support: Responsive customer service and technical assistance

Serving contractors, maintenance professionals, and small-scale manufacturers, ElecDirect provides convenient access to quality crimping tools with the guidance needed to achieve proper results.

Key Product: ElecDirect’s professional ratcheting crimper sets include multiple die options covering popular terminal families for versatile field and workshop applications.

TERMINAL CRIMPER TYPES AND APPLICATIONS

Leading terminal crimper manufacturers develop specialized solutions for different crimping scenarios. Understanding these categories helps you select the right tools for your needs:

HAND CRIMPING TOOLS

The versatile foundation of wire termination, hand crimpers from quality terminal crimper manufacturers provide:

- Portability for Field Work: Lightweight design for mobile applications

- Ratcheting Mechanisms: Ensure complete crimp cycles preventing partial crimps

- Multiple Die Options: Interchangeable tooling for various terminal types

- Ergonomic Handles: Reduced operator fatigue during extended use

- Visual Inspection Access: Open design enables crimp verification

Ideal Applications: Field installation, maintenance work, low-volume production, prototype development, and repair operations.

BENCH CRIMPING TOOLS

Developed for workshop environments, bench-mounted crimpers offer:

- Higher Force Capability: Handle larger terminals and conductors

- Improved Stability: Mounted design ensures consistent positioning

- Compound Leverage: Reduced operator effort for production use

- Quick Die Changes: Efficient terminal changeover in job shops

- Precise Control: Better crimp consistency than hand-held tools

Perfect For: Job shop operations, medium-volume production, quality control testing, and terminal sample preparation.

AUTOMATIC CRIMPING MACHINES

The productivity solution from advanced terminal crimper manufacturers, automatic systems provide:

- Programmable Parameters: Store crimp settings for different terminals

- Integrated Wire Processing: Combined cut, strip, and crimp operations

- Quality Monitoring: Real-time crimp force and height verification

- Production Tracking: Data logging for quality documentation

- Consistent Output: Eliminate variation from operator technique

Ideal For: High-volume manufacturing, automotive harness production, appliance assembly, and applications requiring traceability.

PNEUMATIC CRIMPING TOOLS

Specialized pneumatic crimpers offer unique advantages:

- Adjustable Force Control: Precise pressure regulation for various terminals

- Rapid Cycle Times: Faster than manual tools for production efficiency

- Reduced Operator Fatigue: Air-powered operation minimizes physical effort

- Force Verification: Pressure gauges enable crimp force documentation

- Consistent Quality: Eliminates variations from operator strength

Applications: Assembly line integration, production workstations, high-volume operations, and ergonomically-sensitive environments.

CRIMP QUALITY VERIFICATION: ENSURING RELIABLE CONNECTIONS

PULL FORCE TESTING

Quality crimps must exceed minimum pull force specifications:

| WIRE GAUGE (AWG) | MINIMUM PULL FORCE (lbs) | INDUSTRY STANDARD |

|---|---|---|

| 22 AWG | 7.5 lbs | UL 486A-486B |

| 18 AWG | 15 lbs | UL 486A-486B |

| 14 AWG | 30 lbs | UL 486A-486B |

| 10 AWG | 75 lbs | UL 486A-486B |

Expert Tip: Always verify pull force requirements for your specific terminal and conductor combination. Consult your terminal crimper manufacturer’s specifications for recommended crimp parameters.

CRIMP HEIGHT MEASUREMENT

Proper crimp compression ensures optimal performance:

- Wire Barrel: Deformation should capture all conductor strands without excessive compression

- Insulation Barrel: Should grip insulation without damaging it

- Measurement Tools: Use calibrated crimp height micrometers or optical comparators

- Tolerance Range: Typically ±0.05mm for quality crimps

- Documentation: Record crimp heights for quality system compliance

CROSS-SECTIONAL ANALYSIS

Destructive testing reveals internal crimp quality:

- Strand Capture: All conductor strands should be contained within crimp

- Compression Ratio: Proper deformation without strand breakage

- Void Minimization: Minimal air gaps between strands and terminal

- Insulation Position: Correct location without insulation in wire barrel

Safety Warning: Never use terminals or crimping tools rated for lower voltage than your application requires. Always verify voltage and current ratings meet or exceed your system specifications.

FUTURE TRENDS IN TERMINAL CRIMPING TECHNOLOGY

Forward-thinking terminal crimper manufacturers are pioneering these emerging technologies:

INDUSTRY 4.0 INTEGRATION

Next-generation crimping systems integrate with smart manufacturing:

- Real-Time Quality Monitoring: Continuous crimp force and height verification

- Cloud Data Analytics: Predictive maintenance and process optimization

- Traceability Systems: Complete documentation of every crimp

- Remote Diagnostics: Manufacturer access for troubleshooting and optimization

- Production Scheduling Integration: Seamless MES/ERP connectivity

ADVANCED VISION SYSTEMS

Automated quality verification eliminates human inspection:

- Optical Crimp Verification: High-resolution imaging detects defects

- AI-Powered Inspection: Machine learning identifies quality issues

- 360-Degree Analysis: Complete crimp examination from multiple angles

- Automatic Rejection: Defective crimps removed from production

- Statistical Process Control: Real-time quality trending

ERGONOMIC INNOVATIONS

Reducing operator fatigue increases productivity:

- Electric Assist Technology: Battery-powered hand tools reducing effort

- Balanced Tool Design: Optimized weight distribution minimizing strain

- Adjustable Mechanisms: Customizable to individual operator preferences

- Vibration Reduction: Dampened designs protecting operator health

- Smart Handle Sensors: Monitor usage patterns and suggest improvements

SUSTAINABILITY FOCUS

Environmental considerations driving tool development:

- Energy-Efficient Operation: Reduced power consumption in automated systems

- Recyclable Materials: Tool construction using sustainable components

- Long Service Life: Durable designs minimizing replacement frequency

- Die Refurbishment Programs: Extending tooling life through reconditioning

- Paperless Documentation: Digital quality records reducing waste

HOW TO CHOOSE THE RIGHT TERMINAL CRIMPER FOR YOUR NEEDS

When selecting products from terminal crimper manufacturers, match tool capabilities to your specific requirements:

FOR LOW-VOLUME PRODUCTION & FIELD WORK

Consider these factors when selecting hand tools:

- Terminal Compatibility: Ensure die availability for your terminal families

- Ratcheting Mechanism: Prevents incomplete crimps ensuring quality

- Portability: Weight and size appropriate for mobile applications

- Die Interchangeability: Quick changes for versatile applications

- Warranty Support: Manufacturer backing for tool reliability

Recommended: Ratcheting hand crimpers with interchangeable dies from established manufacturers like Tonful Electric, TE Connectivity, or Molex.

FOR MEDIUM-VOLUME WORKSHOP OPERATIONS

Workshop environments require more robust solutions:

- Bench Mounting Capability: Stable platform for consistent crimps

- Higher Force Capacity: Accommodate larger terminals and conductors

- Quick Die Change Systems: Minimize changeover time between jobs

- Crimp Height Verification: Built-in measurement capabilities

- Service Life Rating: Higher cycle counts for production use

Recommended: Bench-mounted crimpers or pneumatic tools from manufacturers offering strong technical support and die availability.

FOR HIGH-VOLUME PRODUCTION ENVIRONMENTS

Critical systems demand automated crimping solutions:

- Programmable Parameters: Store settings for different terminals

- Integrated Wire Processing: Combined operations improving efficiency

- Quality Monitoring Systems: Real-time verification and documentation

- Production Throughput: Speed matching line requirements

- Connectivity Features: Integration with factory automation systems

- Maintenance Accessibility: Easy serviceability minimizing downtime

Recommended: Automated crimping machines from Tonful Electric, Hua Wei Industrial, or TE Connectivity with proven reliability in production environments.

FOR SPECIALIZED APPLICATIONS

Unique requirements need specialized tools:

- Miniature Terminals: Precision hand tools from Molex or Jeesoon

- Heavy-Duty Power Connections: Hydraulic crimpers from K.S. Terminals

- Harsh Environments: Sealed tools from 3M or TE Connectivity

- Custom Terminal Designs: Manufacturers offering custom die development

- Certification Requirements: Tools meeting aerospace or medical standards

FREQUENTLY ASKED QUESTIONS ABOUT TERMINAL CRIMPERS

HOW DO I KNOW WHAT CRIMP TOOL I NEED FOR MY TERMINALS?

The correct crimping tool depends on your terminal manufacturer and part number. Most quality terminal crimper manufacturers provide comprehensive application guides matching their tools to specific terminal families. Always consult the terminal manufacturer’s specifications for recommended crimping tools and die sets. Using incorrect tooling can result in unreliable connections and safety hazards.

CAN I USE ONE CRIMPING TOOL FOR DIFFERENT TERMINAL BRANDS?

While some crimping tools claim universal compatibility, best practice is matching tools to terminals from the same manufacturer or verifying compatibility through cross-reference guides. Each terminal design has specific crimp parameters – using mismatched tooling may produce connections that don’t meet quality standards. Tonful Electric and other leading manufacturers provide compatibility charts to ensure proper tool-terminal matching.

HOW OFTEN SHOULD CRIMPING TOOLS BE CALIBRATED?

Professional terminal crimper manufacturers recommend annual calibration for production tools, or after every 50,000 crimps, whichever comes first. Hand tools used in field applications should be inspected regularly and recalibrated if crimp quality degrades. Automated systems require more frequent verification – typically quarterly or per manufacturer specifications. Maintain calibration records for quality system compliance.

WHAT CAUSES POOR CRIMP QUALITY?

Common causes of crimp defects include:

- Incorrect crimp height settings (too high or too low compression)

- Wrong die selection for terminal type or wire gauge

- Worn tooling requiring replacement or refurbishment

- Improper wire stripping (too much or too little insulation removed)

- Contaminated terminals or conductors affecting connection integrity

- Incomplete crimp cycles (not fully closing ratcheting tools)

Leading terminal crimper manufacturers like Tonful Electric provide troubleshooting guides to identify and correct quality issues.

ARE RATCHETING CRIMPERS WORTH THE EXTRA COST?

Absolutely. Ratcheting mechanisms ensure complete crimp cycles by preventing premature release, virtually eliminating partial crimps – a leading cause of field failures. While non-ratcheting crimpers cost less initially, the quality consistency and reduced rework from ratcheting tools provides rapid ROI. Most professional terminal crimper manufacturers consider ratcheting mechanisms essential for reliable production and field work.

HOW DO I MAINTAIN MY CRIMPING TOOLS?

Proper maintenance extends tool life and ensures consistent quality:

- Clean regularly – Remove wire debris and contamination

- Lubricate pivot points – Use manufacturer-recommended lubricants

- Inspect dies – Check for wear, damage, or contamination

- Verify calibration – Test crimp dimensions periodically

- Store properly – Protect from moisture and physical damage

- Replace worn components – Don’t compromise quality with degraded tooling

Quality terminal crimper manufacturers provide detailed maintenance procedures and genuine replacement parts.

WHAT SAFETY CERTIFICATIONS SHOULD CRIMPING TOOLS HAVE?

Look for terminal crimper manufacturers whose tools carry appropriate certifications:

- UL Listed – Safety certification for electrical equipment

- CE Marking – European conformity for international sales

- ISO 9001 – Manufacturer quality management systems

- RoHS Compliance – Environmental regulations for electronic equipment

- OSHA Compliance – Workplace safety standards for tools

These certifications ensure products meet established safety and performance standards, protecting both operators and end-users.

TERMINAL CRIMPER SELECTION GUIDE: QUICK REFERENCE

| APPLICATION TYPE | RECOMMENDED TOOL | KEY FEATURES | VOLUME RANGE |

|---|---|---|---|

| Field Installation | Ratcheting Hand Crimper | Portable, multi-die capability | 1-100 crimps/day |

| Maintenance & Repair | Professional Hand Tool | Durable, wide terminal range | 10-500 crimps/day |

| Job Shop Production | Bench Crimper or Pneumatic | Quick die changes, ergonomic | 100-1000 crimps/day |

| Assembly Line | Semi-Automatic Machine | Integrated processing, consistent quality | 500-5000 crimps/day |

| Mass Production | Fully Automatic System | Programmable, quality monitoring | 5000+ crimps/day |

| Miniature Electronics | Precision Hand Crimper | Fine control, small terminal expertise | 50-500 crimps/day |

| Heavy Power Cables | Hydraulic Crimper | High force, large conductor capacity | 10-200 crimps/day |

EXPERT TIPS FOR OPTIMAL CRIMPING RESULTS

✓ Always strip wire to the exact length specified – Too much exposed conductor risks shorts; too little reduces contact area

✓ Verify crimp height with precision tools – Quality crimps fall within ±0.05mm tolerance range

✓ Perform pull tests on sample crimps – Validate your process meets minimum force requirements

✓ Keep tooling clean and properly maintained – Contamination and wear significantly degrade crimp quality

✓ Match wire, terminal, and tool specifications exactly – Mismatched components compromise reliability

✓ Document your crimp parameters – Maintain process records for quality system compliance

✓ Train operators thoroughly – Proper technique is as important as proper tooling

✓ Replace worn dies promptly – Don’t compromise quality for marginal cost savings

CONCLUSION: MAKING THE RIGHT CHOICE IN WIRE TERMINATION EQUIPMENT

Selecting the appropriate terminal crimper manufacturer for your needs involves balancing several factors: tool quality, terminal compatibility, production volume, and long-term support. The top manufacturers highlighted in this guide represent industry leaders who consistently deliver exceptional wire termination equipment.

Remember that reliable crimp connections are the foundation of electrical system safety and reliability. By choosing high-quality terminal crimpers from reputable terminal crimper manufacturers, you’re ensuring that your wire assemblies will perform reliably under real-world conditions, minimizing callbacks, warranty claims, and safety issues.

Whether you’re seeking hand tools for field installation, bench equipment for workshop operations, or automated systems for production environments, partnering with an established manufacturer ensures access to proven technology, comprehensive support, and quality that meets or exceeds industry standards.

For personalized assistance in selecting the ideal terminal crimper solution for your specific requirements, contact Tonful Electric’s dedicated technical team at sales@tonful.com. Our experts can help you navigate the complex world of wire termination equipment to find the perfect balance of quality, productivity, and value for your applications.

ABOUT TONFUL ELECTRIC

Tonful Electric is a leading manufacturer of low-voltage electrical equipment, specializing in precision-engineered terminal crimpers, wire processing tools, and electrical connection solutions. With a commitment to quality, innovation, and customer service, Tonful Electric serves manufacturers, contractors, and maintenance professionals worldwide with reliable equipment that ensures electrical system integrity and safety.

Contact Information:

- Website: https://tonful.com

- Email: sales@tonful.com

- Technical Support: Available for application engineering consultation and crimp quality evaluation

Product Categories:

- Hand Crimping Tools

- Automatic Crimping Machines

- Wire Processing Equipment

- Custom Die Development

- Terminal Blocks and Accessories

This article provides comprehensive information about terminal crimper manufacturers for educational purposes. Always consult manufacturer specifications and follow proper training procedures when using electrical tools and equipment. For critical applications, consider professional installation and certification.