Introduction

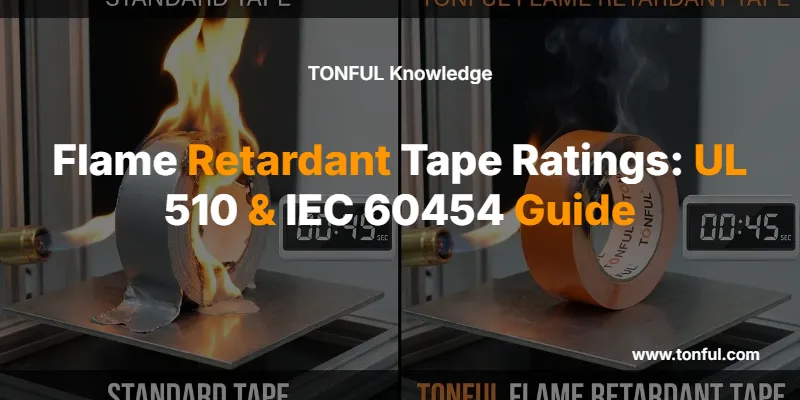

Every year, electrical fires cause billions of dollars in property damage and countless injuries worldwide. A significant percentage of these incidents trace back to inadequate insulation materials that fail to contain flames when electrical faults occur. This is where flame retardant ratings become critical for electrical safety.

Flame retardant ratings provide standardized measures of how electrical insulation materials, particularly tapes, respond to fire exposure. These ratings determine whether a tape will self-extinguish, continue burning, or propagate flames across electrical installations. For engineers, electricians, and procurement professionals, understanding these ratings is not just about compliance—it’s about preventing catastrophic failures.

Two major certification bodies dominate the global landscape: Underwriters Laboratories (UL) in North America and the International Electrotechnical Commission (IEC) internationally. Their respective standards—UL 510 and IEC 60454—define the benchmarks that quality electrical tapes must meet. This comprehensive guide explores these critical flame retardant ratings, helping you make informed decisions for safer electrical installations.

What Are Flame Retardant Ratings?

Flame retardant ratings are standardized classifications that measure a material’s ability to resist ignition and prevent flame propagation. Unlike fireproof materials that won’t burn at all, flame retardant materials are designed to self-extinguish once the ignition source is removed, significantly slowing or stopping fire spread.

For electrical tapes, flame retardancy is measured through controlled laboratory tests that simulate real-world fire conditions. Test specimens are exposed to open flames of specific temperatures and durations while mounted in standardized configurations. Critical parameters evaluated include the time required for self-extinguishment, maximum burn length, whether burning particles drip, and smoke generation characteristics.

The importance of these ratings in electrical applications cannot be overstated. Electrical systems operate at elevated temperatures and carry energy that can spark fires during short circuits, overloads, or insulation failures. A non-flame-retardant tape can act as a fuel source, rapidly spreading fire throughout wiring harnesses, junction boxes, and electrical panels. Conversely, properly rated flame retardant tape creates a protective barrier that contains small electrical fires before they escalate.

Different applications demand varying levels of flame retardancy. Low-voltage residential wiring requires basic flame resistance, while industrial high-voltage installations, automotive harnesses, and marine electrical systems need superior flame retardant performance. Understanding the nuances of electrical tape specifications helps ensure you select products with appropriate safety margins for your specific application.

The testing methodologies also assess secondary fire hazards including smoke density and toxic gas emissions, which are critical factors in occupied spaces where smoke inhalation poses greater immediate danger than flames themselves.

Understanding UL Standards for Electrical Tapes

UL 510 Standard Overview

UL 510 represents the primary North American standard for polyvinyl chloride (PVC), polyethylene (PE), and rubber insulating tapes. Published by Underwriters Laboratories and recognized as ANSI/CAN/UL 510, this standard establishes comprehensive safety requirements for tapes used in electrical insulation applications.

The scope of UL 510 covers thermoplastic and rubber tapes intended for electrical insulation at voltages not exceeding 600V and temperatures up to 80°C (176°F). These tapes are specifically designed for insulating joints and splices in wires and cables according to the National Fire Protection Association’s NFPA 70 (National Electrical Code) in the United States and CSA C22.1 (Canadian Electrical Code) in Canada.

Materials covered under UL 510 include:

- PVC (Polyvinyl Chloride): The most common backing material, offering excellent flame retardancy, flexibility, and electrical insulation properties

- PE (Polyethylene): Provides superior moisture resistance and low-temperature performance

- Rubber-based tapes: Deliver exceptional conformability and self-amalgamating properties

The standard mandates rigorous testing protocols including vertical flame tests where tape-wrapped steel rods are exposed to a controlled flame source. The tape must self-extinguish within specified timeframes without excessive burn propagation. Additional tests evaluate dielectric breakdown voltage (minimum 600V), adhesion strength, unwind force, temperature aging resistance, and cold temperature flexibility.

Quality electrical tape manufacturers ensure their products undergo third-party testing at accredited laboratories to achieve UL 510 certification. The UL listing mark on tape packaging provides immediate verification of compliance, giving specifiers confidence in product safety and performance.

UL 510A for Component Tapes

While UL 510 addresses tapes for field installation on wiring, UL 510A (Component Tapes standard) covers tapes used as components within finished electro-mechanical products during manufacturing. This distinction is crucial for OEM applications where tapes become permanent parts of assemblies.

UL 510A encompasses tapes with specialized constructional features including reinforcement layers, metal foil backings, and both adhesive and non-adhesive configurations. The standard provides guidance for tape selection in product design, ensuring compatibility with end-product safety requirements.

A unique provision in UL 510A allows tapes to be certified based solely on thickness and flammability testing when used in applications where other properties are less critical. This streamlined approach benefits manufacturers who need quick qualification for specific flame retardant requirements without comprehensive electrical and physical testing.

Critical Distinction: UL 94 vs UL 510

A common misconception in the electrical industry involves confusing UL 94 with UL 510. UL 94 is a flammability standard for plastic materials used in device housings and structural components—it is NOT applicable to adhesive tapes. The test methods differ fundamentally: UL 94 tests homogeneous plastic samples in vertical or horizontal orientations at specific thicknesses (0.4mm to 3mm), while UL 510 tests tape applied to substrates as it would be used in practice.

Attempting to apply UL 94 classifications (V-0, V-1, V-2, 5VA, 5VB, HB) to electrical tapes is technically incorrect and can lead to specification errors. The UL 510 flame test methodology specifically addresses how tape behaves when wrapped around conductors or mounted on steel test rods, providing relevant real-world performance data that UL 94 cannot replicate for adhesive tape products.

IEC 60454 Standard Explained

IEC 60454-2: Test Methods

The International Electrotechnical Commission’s IEC 60454-2 establishes standardized test methods for pressure-sensitive adhesive tapes intended for electrical purposes. This comprehensive standard provides the testing foundation upon which tape specifications and classifications are built globally.

IEC 60454-2 defines rigorous procedures for evaluating flame resistance, which remains the cornerstone safety parameter. The flame test involves mounting tape specimens vertically on a metal rod and exposing them to a standardized flame source. The test measures burn length, self-extinguishing time, and whether burning particles fall from the specimen. Tapes must demonstrate self-extinguishing properties within specified limits to pass.

Dielectric breakdown testing under IEC 60454-2 determines the maximum voltage a tape can withstand before electrical failure occurs. Test specimens are positioned between electrodes and subjected to incrementally increasing AC voltage until breakdown. This parameter is critical for ensuring tapes provide adequate electrical insulation in their intended voltage range.

Physical property tests cover tensile strength, elongation, adhesion to various substrates (steel, PVC, backing), and unwind force. These mechanical characteristics ensure tapes can be applied effectively and maintain their protective function throughout their service life. Temperature cycling tests evaluate performance across the rated temperature range, while aging tests simulate long-term exposure to heat, moisture, and environmental conditions.

IEC 60454-3-1: Material Specifications

IEC 60454-3-1 contains detailed specifications for individual tape materials, organized by backing type and adhesive system. The classification system categorizes tapes into types based on their composition and performance characteristics:

- Type 2: General-purpose PVC tapes with rubber-resin adhesive, flame retardant and self-extinguishing, suitable for temperatures up to 80°C

- Type 6: Premium-grade PVC tapes with enhanced flame retardancy meeting IEC 60454-3-1-6/F-PVCP/90 classification, offering superior electrical and mechanical properties

- Type 7: Specialized tapes for specific applications with defined temperature ratings and electrical characteristics

Each type specification includes mandatory performance requirements covering thickness tolerances, tensile strength minimums, dielectric breakdown voltage, flame resistance criteria, adhesion values, and temperature ratings. The standard also defines test conditions, specimen preparation, and acceptance criteria, ensuring consistent evaluation worldwide.

Understanding these classifications helps engineers select appropriate tapes for specific applications. For instance, comparing vinyl versus rubber-based electrical tapes reveals performance trade-offs that influence material selection based on environmental conditions, temperature extremes, and mechanical stress factors.

UL 510 vs IEC 60454: Comprehensive Comparison

| Parameter | UL 510 | IEC 60454 |

|---|---|---|

| Geographic Application | North America (US/Canada) | International (Europe, Asia, rest of world) |

| Voltage Rating | Maximum 600V | Varies by type (typically 600V-1000V) |

| Temperature Rating | Maximum 80°C (176°F) | Type-dependent: 60°C, 80°C, 90°C, 105°C |

| Test Configuration | Tape applied to steel rod | Tape applied to metal rod or direct specimen testing |

| Flame Test Method | Vertical flame, specific duration and flame height | Vertical flame per IEC 60454-2 procedures |

| Key Requirements | Self-extinguishing, no burning drips, limited burn length | Self-extinguishing per classification, controlled burn parameters |

| Certification Body | UL (Underwriters Laboratories) | Various accredited bodies (TÜV, IMQ, VDE, etc.) |

| Standard Harmonization | ANSI/CAN recognized | Adopted as EN standard in Europe |

While UL 510 and IEC 60454 differ in specific test parameters and administrative requirements, both standards share the fundamental goal of ensuring electrical tapes exhibit adequate flame retardant properties. The test methodologies are conceptually similar, involving vertical flame exposure to tape-wrapped specimens and evaluating self-extinguishing behavior.

For global manufacturers like TONFUL, achieving dual certification to both standards provides market access across all major regions. Many electrical tape products now carry multiple certifications including UL, IEC, CSA (Canadian Standards Association), VDE (German), IMQ (Italian), and JIS (Japanese) marks, demonstrating compliance with regional requirements.

The ongoing harmonization efforts between UL and IEC have brought greater alignment in test methods and performance criteria. However, procurement specifications must still explicitly state which standard applies to ensure proper compliance verification. When evaluating alternatives like heat shrink tubing versus electrical tape, understanding these certification differences becomes essential for meeting project requirements.

Flame Retardant Classifications and Performance Levels

Flame retardant ratings categorize tapes based on their self-extinguishing performance and fire propagation characteristics. These classifications provide a clear hierarchy of fire safety performance.

| Classification Level | Burn Time Limit | After-flame Requirements | Typical Applications |

|---|---|---|---|

| Flame Retardant | Self-extinguishes within 60 seconds | No continuous burning after flame removal | General electrical installations, residential wiring |

| High Flame Retardant | Self-extinguishes within 30 seconds | Minimal burn length (<50mm) | Commercial buildings, industrial equipment |

| Superior Flame Retardant | Self-extinguishes within 10 seconds | Very limited burn length (<25mm), no dripping | Critical infrastructure, transportation, marine |

Self-extinguishing properties represent the cornerstone of flame retardant performance. When exposed to an ignition source, flame retardant tapes are formulated to resist combustion and automatically extinguish once the external flame is removed. This behavior prevents small electrical faults from escalating into major fire events.

Flame propagation limits define how far flames can travel along the tape before self-extinguishment occurs. Standards specify maximum burn length measurements, typically ranging from 25mm to 100mm depending on classification. Tapes with shorter burn lengths provide superior fire containment.

Smoke emission and toxicity considerations have gained importance in modern flame retardant ratings. Low-smoke, halogen-free formulations minimize toxic gas generation during combustion, critical for occupied buildings and transportation applications where smoke inhalation poses the primary life-safety threat. While traditional PVC tapes may generate hydrogen chloride gas when burning, newer formulations and alternative materials address these concerns.

Testing Procedures for Flame Retardant Tapes

The vertical flame test represents the standard methodology for evaluating electrical tape flame retardancy under both UL 510 and IEC 60454 standards. Understanding this procedure provides insight into what flame retardant ratings truly measure.

Test specimens consist of tape wrapped around a standardized steel or metal rod in a specified configuration (typically three to four overlapping wraps). The rod is mounted vertically in a draft-free chamber to eliminate variables from air currents. A calibrated Bunsen burner or equivalent flame source is positioned below the specimen at a precise angle (usually 45 degrees) and distance.

The flame is applied for a controlled duration (commonly 15 seconds) at a specified temperature, then removed. Observers measure the time required for any after-flame or after-glow to cease completely. Simultaneously, they measure the vertical burn length from the point of flame application to the furthest extent of damage.

Temperature measurement during testing uses thermocouples positioned at specific locations to verify flame temperature consistency and ensure standardized test conditions. The ambient temperature and humidity are also controlled within specified ranges.

Pass/fail criteria are strictly defined. To achieve flame retardant certification, specimens must self-extinguish within the specified time limit (typically 60 seconds), exhibit burn length below maximum thresholds, produce no burning drips that could ignite cotton placed below, and leave char that remains adhered to the backing without flaking excessively.

Third-party certification by accredited laboratories provides independent verification of compliance. Manufacturers cannot simply self-declare flame retardant ratings—products must undergo testing at facilities recognized by certification bodies like UL, TÜV, or other nationally recognized testing laboratories (NRTLs). This independent oversight ensures consistency and reliability of flame retardant ratings across the industry.

Material Considerations

The backing material fundamentally determines a tape’s flame retardant characteristics. Understanding how different materials perform helps in selecting appropriate tapes for specific fire-safety requirements.

PVC tapes dominate the electrical insulation market due to inherent flame retardant properties. PVC contains chlorine atoms that release hydrogen chloride gas during combustion, which dilutes oxygen concentration and suppresses flame propagation. Modern PVC formulations include additional flame retardant additives such as phosphate esters or antimony trioxide to enhance self-extinguishing performance. PVC tapes readily achieve UL 510 and IEC 60454 Type 2 or Type 6 classifications.

Polyethylene (PE) tapes offer excellent moisture resistance and low-temperature flexibility but require flame retardant additives since PE itself is combustible. Manufacturers incorporate halogenated compounds, phosphorus-based additives, or intumescent materials that swell when heated to create insulating char layers. PE tapes certified to UL 510 provide viable alternatives where moisture resistance outweighs the inherent flame retardancy advantages of PVC.

Rubber-based tapes exhibit superior conformability and self-amalgamating properties, making them ideal for irregular surfaces and moisture sealing applications. Natural and synthetic rubbers typically require substantial flame retardant treatment to meet electrical tape standards. Rubber tapes often use halogenated additives or mineral fillers like aluminum trihydrate to achieve required flame retardant ratings.

The adhesive layer also contributes to overall flame performance. Rubber-resin adhesive systems are formulated with flame retardant compounds matching the backing material’s characteristics. Acrylic adhesives offer different performance profiles, including better temperature resistance but potentially different flame behavior. Understanding these insulating tape working principles ensures proper material selection for demanding applications.

Backing thickness influences flame retardancy, with thicker materials generally providing better fire resistance due to increased thermal mass and longer heat absorption before ignition. However, thickness must be balanced against flexibility and bulk considerations in practical applications.

Industry Applications and Requirements

Different industries impose specific flame retardant rating requirements based on their unique fire-safety challenges and regulatory environments.

Electrical installations governed by NFPA 70 (National Electrical Code) in the United States mandate that insulating tapes used on wire and cable joints meet UL 510 standards. These requirements apply across residential, commercial, and industrial electrical work, ensuring baseline fire safety in all building electrical systems. Tapes must maintain their flame retardant properties throughout the rated temperature range and environmental conditions.

Automotive wiring harnesses present harsh operating environments with temperature extremes, vibration, and exposure to chemicals. Automotive OEMs typically specify tapes meeting both UL and IEC standards, plus additional automotive-specific requirements like SAE standards. The confined spaces and proximity to fuel systems in vehicles demand superior flame retardant performance to prevent catastrophic fires following electrical faults.

Marine and outdoor applications require tapes with flame retardancy that persists despite moisture exposure, salt spray, and UV radiation. Marine electrical systems face particularly stringent requirements due to enclosed vessel environments where escape routes are limited during emergencies. Tapes must maintain their self-extinguishing properties even after prolonged water immersion and weathering.

Industrial equipment in manufacturing facilities, oil and gas operations, and chemical plants requires flame retardant tapes that perform in the presence of flammable atmospheres and explosive dusts. Hazardous location classifications (Class I, II, III, Division 1/2, Zone 0/1/2) impose additional requirements beyond standard flame retardant ratings.

Understanding how to choose appropriate wire connectors and tapes for these diverse applications requires evaluating flame retardant ratings alongside other performance parameters like temperature rating, chemical resistance, dielectric strength, and mechanical durability. The selection process must account for the specific fire hazards and regulatory requirements of each industry sector.

Frequently Asked Questions

What does flame retardant mean for electrical tape?

Flame retardant means the tape is formulated to resist ignition and self-extinguish when exposed to fire. Unlike ordinary tapes that continue burning after a flame source is removed, flame retardant electrical tapes automatically extinguish within specified time limits (typically under 60 seconds), preventing fire spread along wiring systems.

What is the difference between UL 510 and IEC 60454?

UL 510 is the North American standard published by Underwriters Laboratories, covering tapes rated up to 600V and 80°C for US and Canadian markets. IEC 60454 is the international standard used in Europe, Asia, and most of the world, with multiple temperature ratings and slightly different test procedures. Both evaluate flame retardancy, but IEC 60454 offers more granular classification types.

Can I use UL-rated tape in Europe?

While UL 510-rated tapes demonstrate flame retardant properties, European regulations typically require IEC 60454 or EN 60454 certification. For compliance in European markets, specify tapes with appropriate IEC/EN markings. Many global manufacturers offer dual-certified products bearing both UL and IEC approvals to simplify international procurement.

How long does flame retardant tape take to self-extinguish?

Under standard test conditions, flame retardant electrical tapes must self-extinguish within 60 seconds after the ignition source is removed, with premium grades extinguishing in 30 seconds or less. Actual performance depends on factors including tape thickness, material composition, application method, and environmental conditions.

Is UL 94 rating applicable to electrical tapes?

No. UL 94 is specifically for plastic materials used in device housings and structural components, not adhesive tapes. Electrical tape flame retardancy is evaluated under UL 510 (North America) or IEC 60454 (international). Confusing these standards can lead to improper specifications and compliance issues.

Conclusion

Flame retardant ratings serve as essential safety benchmarks in electrical installations worldwide. Understanding the distinctions between UL 510 and IEC 60454 standards empowers engineers, electricians, and procurement professionals to specify appropriate tapes for their specific applications and geographic markets. These certifications provide verified assurance that electrical tapes will perform as expected when fire hazards emerge.

At TONFUL Electric, we recognize that flame retardant ratings represent more than regulatory compliance—they embody our commitment to protecting lives and property through superior electrical products. Our electrical tapes undergo rigorous third-party testing to meet and exceed both UL and IEC flame retardant standards, providing customers with certified safety performance across global markets.

Whether you’re designing electrical systems, maintaining industrial equipment, or sourcing components for manufacturing, selecting properly certified flame retardant tapes is a critical decision. Our technical team at TONFUL stands ready to provide detailed specifications, certification documentation, and application guidance to ensure your projects meet all relevant flame retardant rating requirements. Contact us today to discuss your specific needs and discover how our certified electrical tapes can enhance the safety and reliability of your electrical installations.