Solder seal butt connectors are weatherproof electrical connectors that create permanent, watertight connections by combining heat-shrink tubing with built-in solder rings. These connectors eliminate the need for separate soldering, heat shrink, and weatherproofing steps, making them ideal for automotive, marine, outdoor, and industrial electrical applications where moisture protection is critical.

Unlike traditional butt connectors that rely on mechanical crimping alone, solder seal connectors provide superior electrical conductivity, corrosion resistance, and long-term reliability in harsh environments. You use these connectors when you need permanent, weatherproof electrical connections that meet professional installation standards.

What Are Solder Seal Butt Connectors?

Solder seal butt connectors are three-layer electrical connectors designed for creating permanent, weatherproof wire connections. Each connector contains:

- Outer heat-shrink tubing with adhesive lining for complete moisture seal

- Central solder ring that melts during heating to form electrical bond

- Inner support sleeve that maintains proper wire alignment during installation

When heated with a heat gun, the solder ring melts to create an electrical connection while the heat-shrink tubing forms a watertight seal around the joint. This creates a connection that’s both electrically sound and environmentally protected.

Key Differences: Solder Seal vs Traditional Connectors

| Feature | Solder Seal Butt Connectors | Traditional Crimp Connectors | Wire Nuts | Twist-On Connectors |

|---|---|---|---|---|

| Waterproof Rating | IP67 (when properly installed) | Not waterproof | Not waterproof | Not waterproof |

| Installation Method | Heat gun application | Crimping tool | Hand twisting | Hand twisting |

| Permanent Connection | Yes | Yes | Semi-permanent | Semi-permanent |

| Corrosion Resistance | Excellent | Poor to Fair | Poor | Poor |

| Temperature Range | -55°F to +257°F | -40°F to +221°F | -18°F to +194°F | -18°F to +194°F |

| Vibration Resistance | Excellent | Good | Poor | Poor |

| Professional Appearance | Clean, finished look | Exposed metal | Visible plastic cap | Visible plastic |

| Cost per Connection | $0.50-$2.00 | $0.10-$0.50 | $0.05-$0.25 | $0.05-$0.25 |

| Skill Level Required | Intermediate | Beginner | Beginner | Beginner |

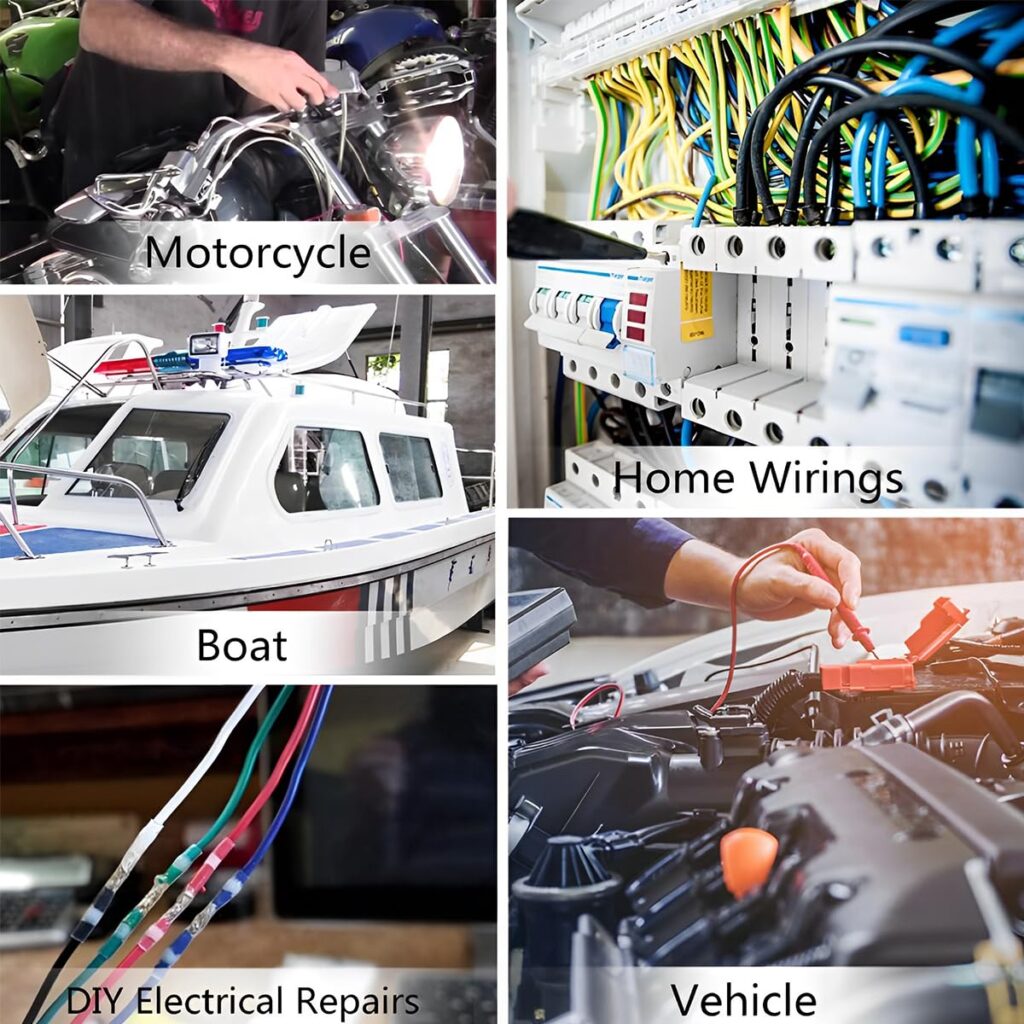

Primary Applications for Solder Seal Butt Connectors

Automotive Electrical Systems

You use solder seal butt connectors in automotive applications where moisture, vibration, and temperature extremes demand reliable connections:

- Trailer wiring harnesses – Prevents corrosion from road salt and moisture

- Under-hood electrical repairs – Withstands engine heat and automotive chemicals

- LED light installations – Creates clean connections for auxiliary lighting systems

- Speaker wire connections – Eliminates audio interference from poor connections

Marine and Boat Electrical Systems

Marine environments require the highest level of moisture protection:

- Navigation light wiring – Coast Guard compliance for safety lighting

- Bilge pump connections – Critical for boat safety systems

- Fish finder and electronics – Protects expensive marine electronics

- Anchor light circuits – Required by maritime regulations

Outdoor and Landscape Lighting

Solder seal connectors excel in outdoor electrical installations:

- Landscape lighting systems – Underground and exposed installations

- Holiday light connections – Permanent outdoor lighting displays

- Security lighting – Motion sensors and flood light installations

- Irrigation control systems – Valve solenoid connections

Industrial and Commercial Applications

Professional installations benefit from the reliability and appearance:

- Control panel wiring – Clean, professional connections

- HVAC system controls – Temperature and moisture resistant

- Security system installations – Tamper-resistant connections

- Emergency lighting circuits – Code-compliant emergency systems

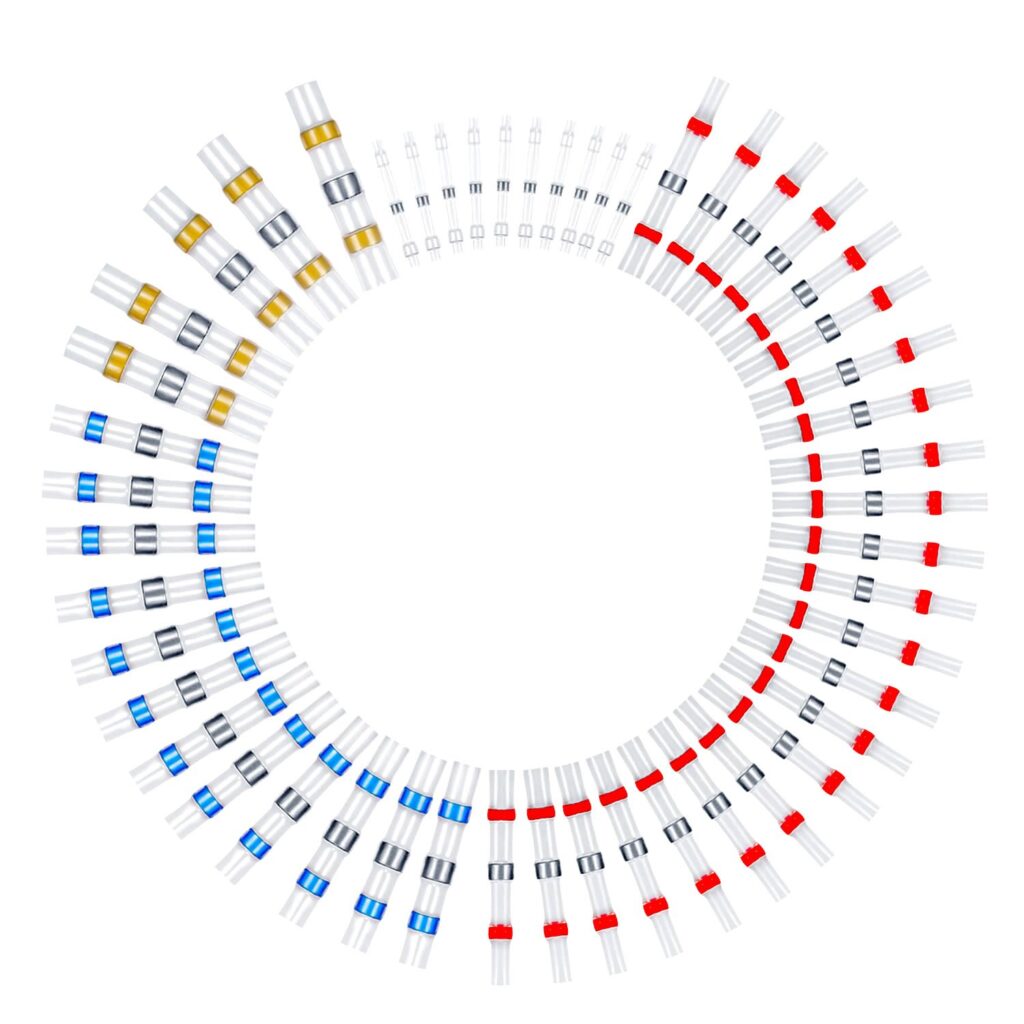

Wire Gauge Compatibility and Selection Guide

| Connector Size | Wire Gauge Range | Color Code | Maximum Current | Typical Applications |

|---|---|---|---|---|

| 22-18 AWG | 22-18 AWG | Red | 7 Amps | Signal wires, small accessories |

| 16-14 AWG | 16-14 AWG | Blue | 15 Amps | Standard automotive circuits |

| 12-10 AWG | 12-10 AWG | Yellow | 25 Amps | Heavy-duty automotive, marine |

| 10-8 AWG | 10-8 AWG | Red | 40 Amps | High-current applications |

Step-by-Step Installation Process

Required Tools and Materials

- Heat gun (minimum 1000 watts recommended)

- Wire strippers

- Solder seal butt connectors (appropriate size)

- Heat-resistant work surface

- Safety glasses

Installation Steps

- Strip wire ends to 1/4 inch – Remove only enough insulation to reach the solder ring center

- Insert first wire – Push stripped end through connector until it reaches the center solder ring

- Insert second wire from opposite end – Ensure both wires meet in the center without overlapping

- Position heat gun 2-3 inches away – Use medium heat setting (around 400°F)

- Apply heat evenly around connector – Rotate connector while heating for 20-30 seconds

- Watch for solder ring to melt – You’ll see the solder flow around the wires

- Continue heating until heat shrink activates – Tubing will shrink tightly around connection

- Allow to cool completely – Don’t move connection for 60 seconds minimum

Professional Installation Best Practices

Pre-Installation Preparation

- Clean wire ends – Remove any corrosion or oxidation before installation

- Test fit connectors – Ensure proper size match before heating

- Plan connection locations – Avoid areas with excessive vibration or heat exposure

- Gather all tools – Complete installation without interruption for best results

Quality Control Checklist

✅ Visual Inspection: Heat shrink has formed tight seal around both wire entries

✅ Tug Test: Gentle pulling should not separate wires from connector

✅ Continuity Test: Use multimeter to verify electrical connection

✅ Moisture Test: No gaps visible between heat shrink and wire insulation

Common Installation Mistakes to Avoid

Wire Preparation Errors

- Over-stripping wires – Exposed copper outside connector creates corrosion points

- Under-stripping wires – Insufficient bare wire prevents proper solder connection

- Dirty or oxidized wire ends – Clean copper is essential for proper solder flow

Heating Technique Problems

- Insufficient heat – Solder won’t flow properly, creating weak connection

- Excessive heat – Can damage wire insulation or connector components

- Uneven heating – Results in partial activation and potential failure points

Code Compliance and Safety Standards

Electrical Code Requirements

Solder seal butt connectors meet requirements for:

- NEC Article 110.14 – Connection reliability standards

- UL 486 Listed – Underground and wet location applications

- ABYC E-11 – Marine electrical standards for boat installations

- SAE J1128 – Automotive wiring harness standards

Safety Certifications

Look for these certifications when selecting connectors:

- UL Listed – Underwriters Laboratories safety certification

- CSA Approved – Canadian Standards Association compliance

- RoHS Compliant – Environmental safety standards

- IP67 Rated – Ingress protection against dust and water

Troubleshooting Common Connection Problems

Poor Electrical Connection

Symptoms: High resistance, voltage drop, intermittent operation

Causes: Insufficient heating, dirty wire ends, wrong connector size

Solution: Cut out connection and re-install with proper preparation

Moisture Infiltration

Symptoms: Corrosion, green residue, connection failure

Causes: Incomplete heat shrink activation, damaged tubing

Solution: Replace connector and ensure complete heat shrink seal

Mechanical Failure

Symptoms: Wires pull out of connector, physical separation

Causes: Excessive mechanical stress, improper installation

Solution: Use strain relief and proper connector sizing for application

When to Call a Professional

Contact a licensed electrician for:

- High-voltage applications (over 50 volts)

- Code-required installations in permanent structures

- Complex automotive systems with computer-controlled circuits

- Marine installations requiring Coast Guard compliance

- Any installation you’re not confident completing safely

Connector Selection Criteria

Environmental Factors

Consider these conditions when selecting solder seal connectors:

Temperature Extremes:

- Standard connectors: -55°F to +257°F operating range

- High-temperature versions available for extreme applications

- Cold weather installations may require special low-temperature solder

Moisture Exposure:

- Marine grade for salt water environments

- Standard grade adequate for fresh water and humidity

- Underground applications require additional protection methods

Chemical Exposure:

- Fuel-resistant versions for automotive fuel system areas

- Chemical-resistant coatings for industrial applications

- Standard connectors adequate for most residential uses

Electrical Requirements

Current Capacity:

- Calculate total circuit current including future additions

- Select connector rated 25% above maximum expected current

- Consider voltage drop in long wire runs

Voltage Rating:

- Standard connectors rated for 600V maximum

- Low-voltage applications (12V) have relaxed requirements

- High-voltage applications require special consideration

Cost-Benefit Analysis

Initial Investment vs Long-Term Value

| Connection Method | Initial Cost | Expected Lifespan | Maintenance Required | Total Cost Over 10 Years |

|---|---|---|---|---|

| Solder Seal Connector | $1.50 | 20+ years | None | $1.50 |

| Crimp Connector + Heat Shrink | $0.75 | 5-10 years | Periodic replacement | $3.00 |

| Wire Nuts | $0.15 | 2-5 years (indoor only) | Frequent replacement | $2.25 |

| Twist + Tape | $0.05 | 1-2 years | Very frequent replacement | $5.00 |

Frequently Asked Questions

What makes solder seal butt connectors better than regular crimp connectors?

Solder seal connectors provide three key advantages: waterproof sealing, superior electrical conductivity through solder bonding, and corrosion resistance. Regular crimp connectors rely only on mechanical pressure and offer no moisture protection.

Can you use solder seal connectors on solid core wire?

Yes, but stranded wire is preferred. Solid core wire requires more careful insertion to prevent damage to the conductor. Ensure the solid wire reaches the center solder ring completely.

How long do solder seal connections last?

Properly installed solder seal connections can last 20+ years in marine and automotive environments. The combination of solder bonding and heat shrink protection provides exceptional longevity.

Are solder seal connectors reusable?

No, solder seal connectors are designed for permanent, one-time use. Once heated and activated, they cannot be removed and reused. Plan connections carefully before installation.

What’s the minimum wire gauge for solder seal connectors?

Most manufacturers offer connectors starting at 22 AWG. Smaller gauge wires may not provide sufficient surface area for reliable solder bonding.

Can you use a hair dryer instead of a heat gun?

Hair dryers don’t provide sufficient heat (typically only 140°F vs required 400°F+). You need a proper heat gun or industrial hair dryer rated for at least 1000 watts.

Do solder seal connectors work with aluminum wire?

Standard solder seal connectors are designed for copper wire only. Aluminum wire requires special connectors with aluminum-compatible solder alloys.

How do you know when the connector is properly activated?

You’ll see the solder ring melt and flow around the wires, and the heat shrink tubing will contract tightly. The connector should feel solid with no movement between wire and connector.

Professional Recommendations and Next Steps

Quality Brand Selection

Choose connectors from established manufacturers with proven track records:

- Look for UL Listed certification on packaging

- Verify temperature and current ratings match your application

- Consider marine-grade versions for the highest reliability

- Buy from authorized electrical supply distributors

Professional Installation Services

For critical applications, consider hiring certified technicians:

- IPC certified for electronics applications

- ABYC certified for marine installations

- ASE certified for automotive electrical work

- Licensed electricians for permanent building installations

Expert Recommendation: Invest in quality tools and take time to practice proper technique. Well-executed solder seal connections provide decades of reliable service while poor installations can fail within months.

This guide provides general information for educational purposes. Always consult local electrical codes and qualified professionals for specific installations. Improper electrical work can result in fire, injury, or death.