Why Electrical Connector Kits Are Essential for Automotive Professionals

For automotive mechanics, repair shop owners, and fleet maintenance professionals, having a comprehensive electrical connector kit is not just convenient—it’s essential. Electrical connectors are the weakest link in any vehicle’s electrical system, and corroded, brittle, or broken connectors are among the most overlooked causes of starting problems, electrical failures, and diagnostic headaches.

A well-stocked electrical connector kit enables you to make fast, economical repairs without waiting for individual components or compromising on quality. Whether you’re troubleshooting a malfunctioning sensor, repairing a damaged wiring harness, or installing aftermarket accessories, the right connector kit saves time and ensures reliable connections that withstand vibration, moisture, and temperature extremes.

This comprehensive guide examines the top five types of electrical connector kits every automotive professional should have in their toolbox, along with detailed specifications, comparison tables, and practical buying advice to help you make informed purchasing decisions.

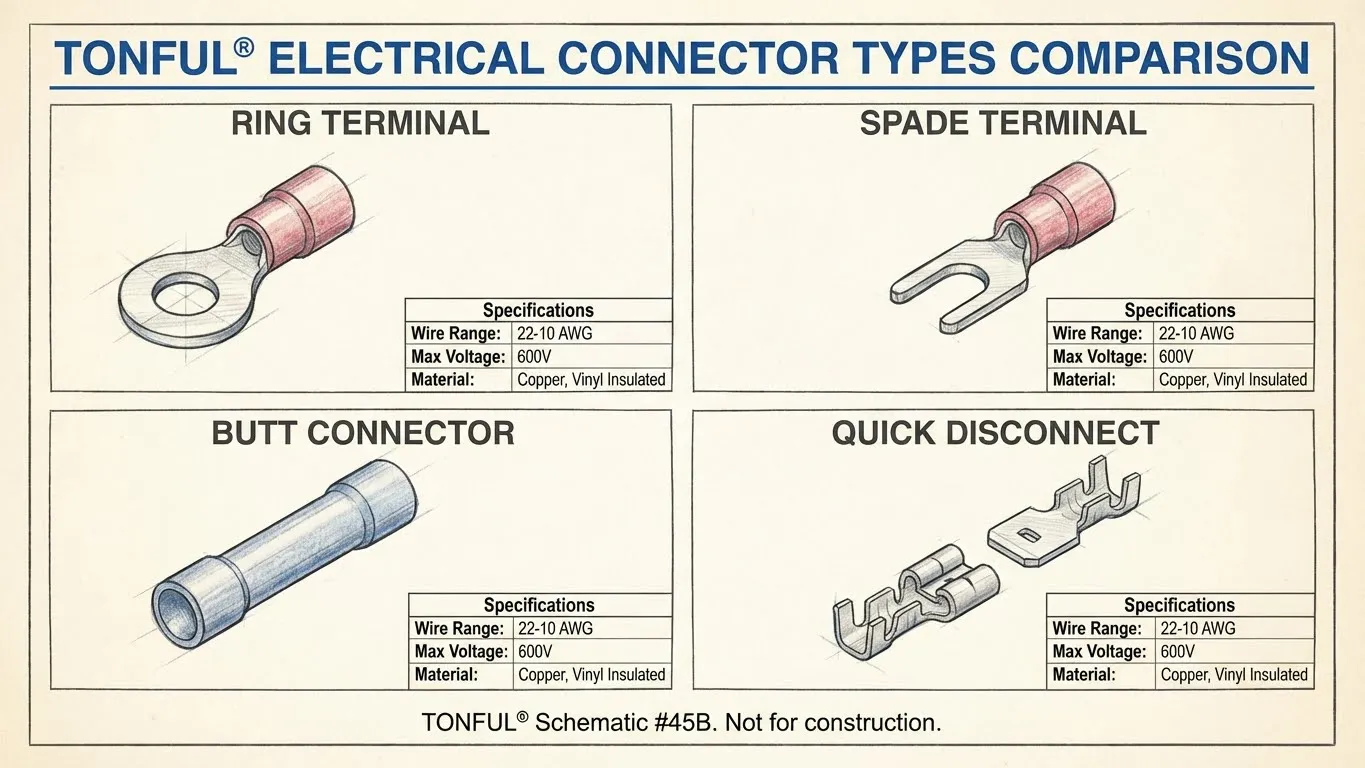

1. Crimp Terminal Assortment Kits

Crimp terminal assortment kits are the foundation of any automotive electrical repair toolkit. These comprehensive sets include a variety of wire terminal types in multiple sizes and configurations, allowing mechanics to handle virtually any wiring repair or installation task.

Key Features and Benefits

A quality crimp terminal assortment kit typically contains 300-1200+ pieces, including:

- Ring terminals for secure bolt-down connections

- Spade (fork) terminals for easy disconnect applications

- Butt connectors for splicing wires together

- Quick disconnect terminals for removable connections

- Pin terminals for connector housings

The best kits use tinned copper construction, which provides superior conductivity and corrosion resistance compared to standard copper. Color-coded insulation (typically red, blue, and yellow) corresponds to wire gauge ranges, making selection quick and reducing installation errors.

Applications in Automotive Repair

Crimp terminal assortment kits excel in numerous automotive applications:

- Battery cable repairs and upgrades

- Sensor and actuator wiring connections

- Aftermarket accessory installations (lights, audio systems, gauges)

- Trailer wiring harness repairs

- Ground strap replacements

- Starter and alternator circuit repairs

Wire Gauge Compatibility

Quality assortment kits cover the most common automotive wire gauges:

- Red (22-16 AWG): Low-current circuits, sensors, signal wires

- Blue (16-14 AWG): Medium-current circuits, lighting, accessories

- Yellow (12-10 AWG): High-current circuits, starter systems, battery cables

What to Look For

When selecting a crimp terminal assortment kit:

- Material quality: Look for terminals made from tinned copper rather than brass or standard copper

- Insulation type: Nylon insulation offers better heat resistance than vinyl

- Crimp design: Double-crimp designs (separate conductor and insulation crimps) provide superior holding strength

- Organization: Compartmentalized storage boxes prevent mixing and damage

- Quantity distribution: Ensure the kit has adequate quantities of your most-used terminal types

2. Waterproof Connector Kits

For applications exposed to moisture, salt, and harsh environmental conditions, waterproof wire connectors are non-negotiable. These specialized electrical connector kits feature sealed designs that prevent water intrusion, corrosion, and electrical failures.

Key Features and Benefits

Premium waterproof connector kits include:

- IP67/IP68 rated connectors that withstand temporary or continuous submersion

- Silicone or rubber cable seals that create watertight barriers around individual wires

- Locking mechanisms that ensure secure mating and prevent accidental disconnection

- UV-resistant housings for outdoor and underbody installations

- Multiple pin configurations (1-12 pins) for various circuit requirements

Applications in Automotive Repair

Waterproof connector kits are essential for:

- Marine and boat electrical systems

- Off-road vehicle lighting installations

- Trailer connections and wiring

- Underbody sensor connections (ABS, oxygen sensors)

- Outdoor lighting systems

- Engine compartment repairs where moisture exposure is common

Technical Specifications

Professional-grade waterproof connector kits typically support:

- Wire gauge range: 12-22 AWG

- Voltage rating: 12-24V DC (some up to 80V)

- Current capacity: 1.5A to 30A depending on pin size

- Temperature range: -40°C to +125°C

- IP rating: IP67 (temporary submersion) or IP68 (continuous submersion)

Selection Criteria

When choosing waterproof wire nuts and connector kits:

- Seal quality: Double O-ring seals provide superior protection

- Pin material: Gold-plated contacts resist corrosion better than tin-plated

- Housing material: PA66 nylon offers excellent chemical and UV resistance

- Complete kits: Ensure the kit includes housings, pins, seals, and any required tools

- Manufacturer reputation: Choose established brands with proven reliability records

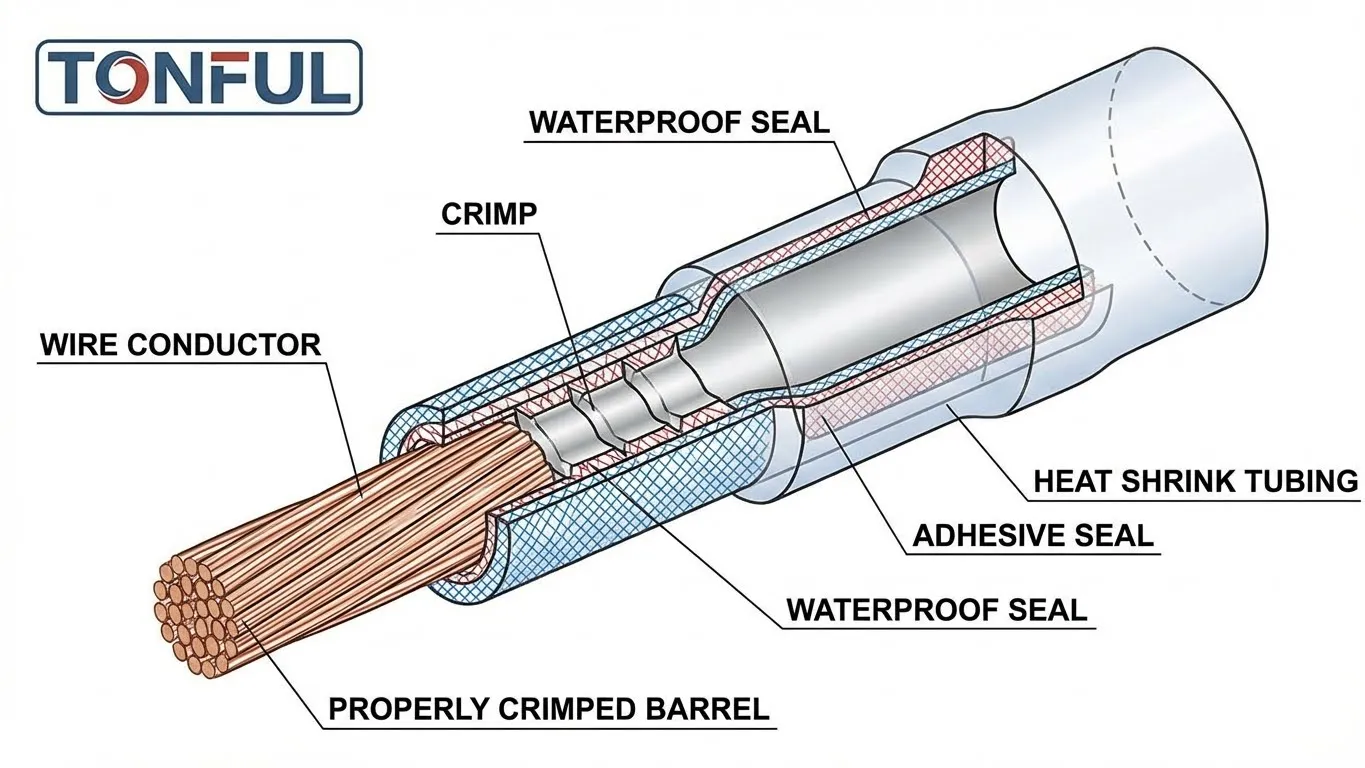

3. Heat Shrink Terminal Kits

Heat shrink terminals combine the mechanical strength of crimp connections with the environmental protection of adhesive-lined heat shrink tubing, creating sealed connections that resist moisture, vibration, and corrosion.

Key Features and Benefits

Advanced heat shrink terminal kits offer:

- Dual-wall construction with adhesive inner layer that melts and seals during heating

- Transparent or translucent tubing allowing visual inspection of crimp quality

- Marine-grade tinned copper for maximum corrosion resistance

- Color-coded sizing for quick wire gauge identification

- Pre-assembled design that speeds installation

Applications in Automotive Repair

Heat shrink terminal kits excel in demanding environments:

- Marine electrical systems and boat wiring

- Classic car restoration projects requiring period-correct sealed connections

- High-vibration applications (motorcycles, off-road vehicles)

- Engine compartment connections exposed to heat and moisture

- Outdoor and underbody wiring repairs

- Trailer wiring that experiences frequent flexing

Technical Specifications

Quality heat shrink terminal kits provide:

- Wire gauge coverage: 22-10 AWG (most automotive applications)

- Shrink ratio: 3:1 or 4:1 for comprehensive wire size coverage

- Operating temperature: -55°C to +125°C after installation

- Shrink temperature: 90-120°C (heat gun or torch application)

- Adhesive type: Hot-melt adhesive for watertight seal

- Insulation material: Polyolefin or dual-wall cross-linked polyolefin

Installation Best Practices

For optimal results with heat shrink wire connectors:

- Strip wires precisely to manufacturer specifications (typically 5-7mm)

- Crimp properly before applying heat—the mechanical connection must be secure first

- Apply heat evenly using a heat gun (preferred) or torch with careful technique

- Heat until adhesive flows and seals both ends—look for adhesive extruding slightly

- Allow to cool completely before handling or subjecting to stress

4. Quick Disconnect Terminal Kits

Quick disconnect terminal kits (also called Faston terminals or spade connectors) enable easy connect/disconnect functionality without tools, making them ideal for components requiring periodic removal or testing.

Key Features and Benefits

Professional quick disconnect kits include:

- Male and female terminals in matched pairs

- Multiple tab widths (0.110″, 0.187″, 0.250″ most common in automotive)

- Fully insulated or non-insulated options depending on application requirements

- Locking tabs that prevent accidental disconnection

- Variety of wire gauge sizes to handle different current loads

Applications in Automotive Repair

Quick disconnect terminals are preferred for:

- Automotive relay connections

- Horn circuits and switches

- Blower motor connections

- Ignition system components

- Battery disconnect switches

- Diagnostic connector repairs

- Modular wiring that requires frequent access

Sizing and Specifications

Quick disconnect terminals are sized by tab width:

| Terminal Size | Tab Width | Common Wire Gauge | Typical Current Rating | Common Applications |

|---|---|---|---|---|

| .110″ | 2.8mm | 22-16 AWG | 10-15A | Sensors, relays, small motors |

| .187″ | 4.75mm | 16-14 AWG | 15-20A | Horns, switches, medium motors |

| .250″ | 6.3mm | 14-10 AWG | 20-30A | Starter solenoids, high-current relays |

Selection Criteria

When purchasing quick disconnect terminals:

- Tab width compatibility: Match terminals to mating connector tabs precisely

- Insulation barrel design: Funnel-entry barrels reduce wire hang-ups during crimping

- Contact material: Tin-plated brass offers good conductivity and durability

- Lock mechanism: Spring tabs or locking ears prevent vibration-induced disconnection

- Kit assortment: Balanced quantities of male, female, and both insulated/non-insulated types

5. Automotive Wire Pin Connector Kits

Multi-pin automotive connector kits provide complete solutions for custom harness fabrication, connector repairs, and electrical system modifications. These kits include housings, pins, seals, and often specialized extraction tools.

Key Features and Benefits

Comprehensive multi-pin connector kits contain:

- Connector housings in multiple pin configurations (2-12 pins typical)

- Male and female pins (crimp-style contacts)

- Individual wire seals for each pin position

- Cavity plugs for unused positions

- Secondary locks for extra connection security

- Pin extraction tools for connector repair and rework

Popular Connector Types

Professional automotive connector kits often include these industry-standard types:

- Deutsch DT series: Environmentally sealed, vibration-resistant

- Delphi (Aptiv) Weather Pack: Moisture-sealed, moderate current capacity

- Metri-Pack series: Compact, high-density connections

- AMP Superseal: Heavy-duty sealed connections for high-current applications

Applications in Automotive Repair

Multi-pin connector kits are essential for:

- Engine control module (ECM) harness repairs

- Sensor connector rebuilding (oxygen sensors, MAF, throttle position)

- Custom engine swaps and modifications

- Aftermarket ECU installations

- Fuel injector harness repairs

- Transmission control module connections

- Body control module wiring

Technical Considerations

When working with automotive electrical connectors:

- Pin size standards: Most automotive applications use size 16 (16-20 AWG) or size 12 (12-14 AWG) contacts

- Sealing capability: Look for connectors rated IP67 or better for underhood applications

- Current rating: Verify pin current capacity matches circuit requirements

- Temperature range: Underhood connectors should handle -40°C to +150°C minimum

- Tool compatibility: Ensure you have the correct crimping tool for the pin type

Electrical Connector Kit Comparison Table

| Kit Type | Typical Piece Count | Wire Gauge Range | Primary Applications | Waterproof Rating | Average Price Range |

|---|---|---|---|---|---|

| Crimp Terminal Assortment | 300-1200 | 22-10 AWG | General wiring, accessories, repairs | No (unless heat shrink) | $25-$80 |

| Waterproof Connector Kit | 50-500 | 16-20 AWG | Marine, outdoor, underbody | IP67/IP68 | $30-$120 |

| Heat Shrink Terminal Kit | 100-500 | 22-10 AWG | Marine, restoration, sealed repairs | Yes (when installed) | $35-$100 |

| Quick Disconnect Kit | 100-400 | 22-10 AWG | Relays, switches, modular wiring | No | $20-$60 |

| Multi-Pin Connector Kit | 20-200 sets | 16-22 AWG | Harness repair, ECM/PCM, sensors | Varies by type | $40-$200+ |

Insulated vs. Non-Insulated Terminals Comparison

| Feature | Insulated Terminals | Non-Insulated Terminals |

|---|---|---|

| Electrical isolation | Built-in insulation sleeve | Requires separate heat shrink or tape |

| Installation speed | Faster—single crimp operation | Slower—requires additional insulation step |

| Vibration resistance | Good—insulation provides strain relief | Excellent—when properly heat shrunk |

| Waterproof capability | Limited—unless heat shrink type | Excellent—with marine-grade heat shrink |

| Visual inspection | Difficult—crimp hidden by insulation | Easy—crimp quality visible |

| Cost per terminal | Lower unit cost | Higher (terminal + heat shrink) |

| Professional applications | General automotive, accessories | Marine, critical systems, permanent installations |

| Tool requirements | Standard insulated terminal crimper | Open barrel crimper + heat gun |

Connector Material Comparison

| Material | Conductivity | Corrosion Resistance | Cost | Best Applications |

|---|---|---|---|---|

| Copper | Excellent (100%) | Poor—oxidizes quickly | Low | Dry, protected environments only |

| Tinned Copper | Excellent (98%) | Excellent—tin coating prevents oxidation | Medium | Marine, underhood, general automotive |

| Brass | Good (28%) | Good—natural patina protection | Low-Medium | Low-current, dry applications |

| Gold-Plated Copper | Excellent (100%) | Excellent—no oxidation | High | Critical sensors, low-voltage signals |

Quality Indicators: How to Identify Premium Connector Kits

Not all electrical connector kits deliver the same performance and reliability. Here are key quality indicators to guide your purchasing decisions:

Material Quality

- Tinned copper construction: Superior to brass or standard copper for automotive applications

- Pure copper content: Look for 99%+ copper for optimal conductivity

- Insulation material: Nylon insulation outperforms vinyl in heat resistance and durability

- Plating quality: Consistent, smooth plating without thin spots or flaking

Manufacturing Standards

Professional-grade connector kits should meet or exceed:

- UL (Underwriters Laboratories) listing: Verifies safety and performance standards

- CSA (Canadian Standards Association) certification: International quality recognition

- IATF 16949 certification: Automotive industry quality management standard

- RoHS compliance: Environmental safety standards for electrical components

Design Features

Premium connectors incorporate thoughtful design elements:

- Funnel-entry barrels: Reduce wire strand hang-ups during crimping

- Wire stop indicators: Ensure consistent wire insertion depth

- Crimp inspection windows: Allow visual verification of proper crimp (on insulated terminals)

- Color-coded sizing: Red, blue, yellow correspond to standard wire gauge ranges

- Embossed sizing marks: Permanent identification that won’t wear off

Packaging and Organization

Quality kits provide:

- Compartmentalized storage: Prevents mixing and damage during storage/transport

- Clear labeling: Each compartment clearly marked with terminal type and wire gauge

- Durable cases: Impact-resistant plastic with secure latches

- Refillable design: Allows restocking individual terminal types as needed

Buying Tips for Automotive Professionals

Assess Your Needs

Before purchasing electrical connector kits:

- Analyze your typical repairs: Track the connector types and sizes you use most frequently

- Consider your customer base: Fleet maintenance requires different kits than classic car restoration

- Evaluate environmental factors: Marine and off-road shops need more waterproof options

- Calculate volume requirements: High-volume shops benefit from bulk purchasing

Prioritize Versatility

For maximum flexibility:

- Start with a comprehensive crimp terminal assortment covering 22-10 AWG

- Add specialized kits based on your specific repair needs

- Keep waterproof connectors on hand even if not used daily—emergency repairs demand them

- Stock both insulated and non-insulated terminals for different quality requirements

Consider Total Cost of Ownership

Premium kits cost more upfront but deliver:

- Fewer comeback repairs: Quality connections don’t fail prematurely

- Faster installations: Well-designed terminals crimp consistently and reliably

- Professional reputation: Your work quality reflects in every connection

- Reduced waste: Quality terminals don’t crack, break, or fail during installation

Build Relationships with Suppliers

Partnering with reputable manufacturers like TONFUL provides:

- Consistent quality: Standardized specifications across orders

- Technical support: Expert guidance on product selection and application

- Bulk pricing: Volume discounts for professional users

- Custom solutions: Specialized kits tailored to your specific needs

Frequently Asked Questions

What wire gauge should I use with electrical connector kits?

Wire gauge selection depends on the circuit’s current requirements. For automotive applications: 22-18 AWG for low-current signals and sensors (up to 5A), 16-14 AWG for lighting and accessories (5-20A), and 12-10 AWG for high-current circuits like starter systems and heavy accessories (20-40A). Always match the connector’s wire gauge rating to your wire size—using mismatched components results in unreliable crimps and potential failures.

Are insulated terminals better than non-insulated for automotive use?

Both have appropriate applications. Insulated terminals offer faster installation and built-in electrical isolation, making them ideal for general automotive repairs and accessory installations. However, non-insulated terminals with marine-grade heat shrink provide superior waterproofing and vibration resistance for permanent, critical connections. For marine, underhood, and restoration work, non-insulated terminals with proper heat shrink deliver better long-term reliability.

How do I know if my crimp connection is secure?

A proper crimp should: (1) show complete deformation of the terminal barrel with wire strands visible through crimp windows, (2) withstand a pull test of at least 15 pounds without separation, (3) have the conductor fully seated in the terminal barrel with no exposed wire strands, and (4) show no cracking or splitting of the terminal or insulation. Use a ratcheting crimping tool that applies consistent force—these tools won’t release until proper crimp pressure is achieved.

Can I reuse automotive electrical connectors?

Generally, no—crimp terminals are designed for single use. The crimping process permanently deforms the terminal barrel, and attempting to reuse it compromises the mechanical and electrical connection. For multi-pin connector housings, you can typically reuse the plastic housing if undamaged, but always install fresh pins/terminals. Waterproof wire nuts and sealed connectors should never be reused as the sealing elements lose effectiveness after initial installation.

What’s the difference between crimp and solder connections?

Crimping provides a cold mechanical connection that’s faster, more consistent, and better suited for vibration-prone automotive environments. Soldering creates a metallurgical bond that conducts slightly better but requires skill, takes longer, and exposes wires to heat that can damage insulation. For professional automotive repair, crimping is preferred—it’s faster, more reliable in vibration, and when done properly with quality terminals, provides equivalent electrical performance to soldering.

How do I maintain and organize my electrical connector kits?

Store kits in their original compartmentalized cases in a dry location away from extreme temperatures. Label each compartment clearly with terminal type and wire gauge. Periodically inspect terminals for corrosion or damage—discard any compromised components. Keep your crimping tools calibrated and maintained according to manufacturer specifications. For high-volume shops, consider implementing an inventory management system to track usage and trigger reorders before supplies run out. Separate automotive-grade components from marine-grade to prevent mixing and ensure proper application selection.

Conclusion

Investing in quality electrical connector kits is essential for any automotive professional committed to delivering reliable, long-lasting repairs. The five kit types covered—crimp terminal assortments, waterproof connectors, heat shrink terminals, quick disconnects, and multi-pin connectors—form a comprehensive foundation for handling virtually any automotive electrical repair or installation.

When selecting connector kits, prioritize material quality, manufacturing standards, and design features that enhance reliability and ease of installation. TONFUL’s comprehensive range of electrical terminals and connectors provides professional-grade solutions backed by rigorous quality control and industry certifications.

Remember that the electrical connections you create today directly impact your reputation and your customers’ satisfaction. Choosing premium connector kits may cost more initially, but the reduction in callbacks, the time saved during installation, and the confidence of knowing your work will last make them an investment that pays dividends on every job.

For wholesale inquiries, technical specifications, or guidance on selecting the right connector kits for your specific applications, contact TONFUL’s technical support team—we’re committed to helping automotive professionals deliver exceptional results.