Ring insulated terminals are electrical connectors designed to create secure, permanent connections between wires and screw-type terminals or studs. These terminals feature a circular ring shape that fits over bolts or screws, providing maximum contact area and preventing accidental disconnection in electrical systems ranging from automotive to industrial applications.

Key Benefit: Ring terminals offer the most secure wire-to-terminal connection available, making them essential for critical electrical connections where safety and reliability cannot be compromised.

What Are Ring Insulated Terminals?

Ring insulated terminals are electrical connectors consisting of a metal ring connected to a barrel-shaped crimp section, all encased in colored vinyl insulation. The ring portion creates a permanent mechanical connection around screws or bolts, while the barrel section crimps onto wire strands to establish electrical continuity.

Primary Components:

- Metal ring: Provides mechanical connection around terminals

- Crimp barrel: Secures to wire strands through compression

- Vinyl insulation: Color-coded protection preventing short circuits

- Seam construction: Overlapping metal edges for enhanced conductivity

Key Differences: Ring Terminals vs Other Terminal Types

| Feature | Ring Terminals | Spade Terminals | Butt Connectors | Wire Nuts |

|---|---|---|---|---|

| Connection Security | Permanent, cannot slip off | Can slide off if loose | Permanent splice only | Temporary connection |

| Contact Area | Maximum (360° contact) | Limited (180° contact) | End-to-end only | Wire-to-wire twist |

| Vibration Resistance | Excellent | Poor to moderate | Excellent | Poor |

| Installation Ease | Requires screw removal | Quick slip-on | Simple crimp | Hand twist only |

| Current Capacity | Highest for size | Moderate | High | Limited by twist |

| Code Compliance | UL Listed options | UL Listed options | UL Listed | Limited applications |

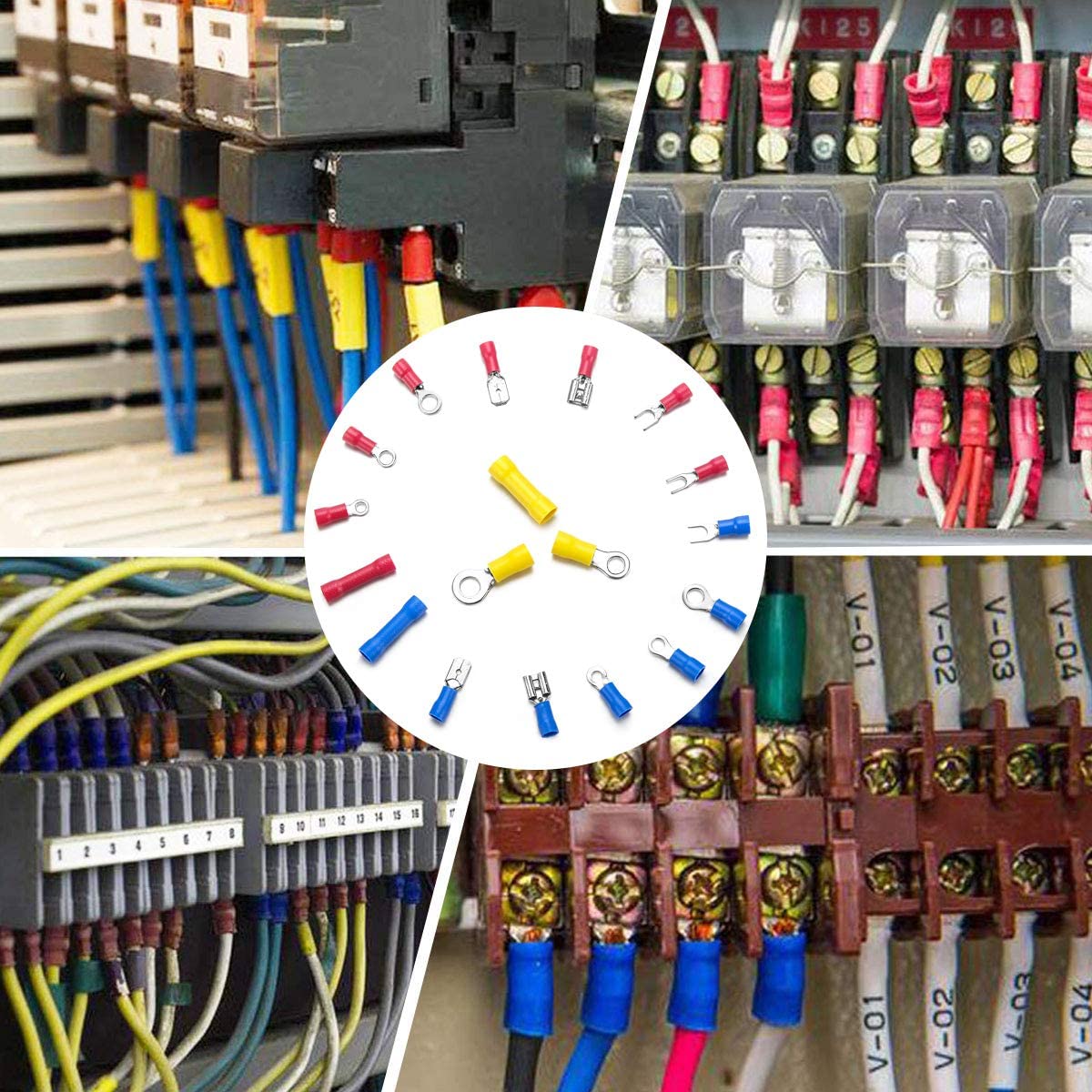

Ring Terminal Applications and Use Cases

Automotive Applications

Ring terminals excel in automotive electrical systems where vibration and temperature extremes demand reliable connections:

- Battery terminals: Positive and negative battery cable connections

- Ground straps: Chassis and engine grounding systems

- Starter motor connections: High-current starter cable terminations

- Alternator wiring: Output terminal connections

- Trailer wiring: Seven-way connector applications

Industrial Electrical Systems

Manufacturing and industrial facilities rely on ring terminals for equipment connections:

- Motor terminal boxes: Three-phase motor connections

- Control panel wiring: Contactor and relay terminations

- Power distribution: Subpanel and disconnect connections

- Grounding systems: Equipment grounding conductor terminations

- Transformer connections: Secondary terminal connections

Residential Electrical Applications

Home electrical systems use ring terminals for specific connection requirements:

- Panel board connections: Main breaker and feeder terminations

- Water heater connections: Element and thermostat wiring

- HVAC systems: Compressor and fan motor connections

- Appliance wiring: Range, dryer, and large appliance connections

- Generator transfer switches: Manual and automatic transfer connections

Ring Terminal Selection Guide

Wire Gauge Compatibility Chart

| Terminal Size | Wire Gauge Range | Stud Size | Color Code | Max Ampacity |

|---|---|---|---|---|

| 22-18 AWG | 22-18 AWG | #6, #8, #10 screws | Red | 15 Amps |

| 16-14 AWG | 16-14 AWG | #6, #8, #10 screws | Blue | 25 Amps |

| 12-10 AWG | 12-10 AWG | 1/4″ to 3/8″ studs | Yellow | 35 Amps |

| 8 AWG | 8 AWG | 5/16″ to 1/2″ studs | Red | 50 Amps |

| 6 AWG | 6 AWG | 3/8″ to 5/8″ studs | Blue | 65 Amps |

| 4 AWG | 4 AWG | 1/2″ to 3/4″ studs | Yellow | 85 Amps |

What Should You Look for When Choosing Ring Terminals?

Material Quality Factors:

- Copper construction: Pure copper provides best conductivity

- Tin plating: Prevents corrosion in marine environments

- UL listing: Ensures compliance with electrical codes

- Temperature rating: Match to application environment

Installation Requirements:

- Stud size compatibility: Ring must fit securely over bolt

- Wire gauge match: Terminal must accommodate wire size

- Insulation type: Vinyl for general use, heat-shrink for moisture

- Crimp tool compatibility: Match to available installation tools

Expert Tip: Always select ring terminals one size larger than the minimum wire gauge requirement to ensure proper crimp compression and maximum conductivity.

Step-by-Step Ring Terminal Installation Process

Required Tools and Materials

- Crimp tool: Ratcheting type for consistent compression

- Wire strippers: Match to wire gauge being used

- Heat gun: For heat-shrink insulated terminals

- Electrical tape: Additional insulation if needed

- Torque wrench: For proper terminal screw tightening

Installation Procedure

Step 1: Wire Preparation

Strip wire insulation to expose copper strands equal to the barrel length of the terminal. Avoid nicking or cutting individual strands during stripping process.

Step 2: Terminal Insertion

Insert stripped wire fully into the terminal barrel until copper strands are visible at the barrel end. Ensure no insulation enters the crimp area.

Step 3: Crimping Process

Position crimp tool over the terminal barrel and compress using firm, steady pressure. Ratcheting tools automatically release when proper compression is achieved.

Step 4: Connection Verification

Perform pull test by gently tugging on the wire. Properly crimped terminals will not separate under moderate force.

Step 5: Terminal Installation

Place ring terminal over bolt or screw, ensuring flat contact with the terminal surface. Tighten to manufacturer’s specified torque value.

Safety Warning: Electrical Hazards

⚠️ DANGER: Always disconnect power before installing ring terminals. Failure to de-energize circuits can result in electrical shock, burns, or death. Verify power is off using a calibrated voltage tester before beginning work.

⚠️ CODE COMPLIANCE: Ring terminal installations must comply with NEC Article 110.14 for connection requirements and Article 250 for grounding applications.

Common Ring Terminal Problems and Solutions

Poor Crimping Issues

Problem: Wire pulls out of terminal or connection becomes loose over time.

Solution: Use proper crimp tool with ratcheting mechanism. Ensure wire strands fill the entire barrel before crimping. Replace over-crimped or under-crimped terminals immediately.

Corrosion Problems

Problem: White or green buildup appears on terminal connections.

Solution: Use tin-plated terminals in marine environments. Apply dialectric grease to connections exposed to moisture. Consider heat-shrink terminals for outdoor applications.

Overheating Connections

Problem: Terminal becomes hot during operation or shows burn marks.

Solution: Verify terminal ampacity matches circuit load. Check for loose connections and retighten to specified torque. Replace damaged terminals and investigate overcurrent conditions.

Wrong Size Selection

Problem: Terminal too small for stud or too large for wire gauge.

Solution: Reference manufacturer sizing charts before purchase. Use wire gauge strippers to verify actual wire size. Select terminals based on both wire gauge and stud diameter requirements.

Ring Terminal Quality and Certification Standards

UL Certification Requirements

Ring terminals used in commercial and residential applications must meet UL 486A standards for wire connectors. Look for UL marking on terminal packaging and individual components.

NEC Code Compliance

National Electrical Code Article 110.14(A) requires all electrical connections to be made with approved fittings. Ring terminals must be listed for the specific voltage and current rating of the circuit.

Industry Standards

- ASTM B298: Specification for silver-coated copper wire

- SAE J1127: Automotive electrical terminal specifications

- IEC 60947: International connector standards

- RoHS Compliance: Lead-free materials for environmental safety

Expert Selection Criteria for Ring Terminals

Professional Installation Tips

Material Selection Priority:

- Copper core: Essential for maximum conductivity

- Tin or silver plating: Required for corrosion resistance

- Vinyl insulation: Adequate for most indoor applications

- Heat-shrink options: Necessary for outdoor or marine use

Size Selection Method:

- Measure wire gauge: Use wire gauge tool for accuracy

- Determine stud size: Measure bolt or screw diameter

- Check ampacity requirements: Verify current capacity needs

- Confirm code compliance: Ensure UL listing for application

Expert Recommendation: For critical applications like main electrical panels, always use tin-plated copper terminals with UL listing. The additional cost provides significant reliability improvements over basic vinyl-insulated options.

Frequently Asked Questions

What makes ring terminals different from spade terminals?

Ring terminals completely encircle the mounting bolt, preventing accidental disconnection due to vibration or loose hardware. Spade terminals can slide off loose connections, making rings the safer choice for permanent installations.

Can you reuse ring terminals after removal?

No, ring terminals are designed for one-time use. The crimping process permanently deforms the metal barrel, and attempting to reuse creates unreliable connections that violate electrical code requirements.

What wire gauge range works with 12-10 AWG ring terminals?

Standard 12-10 AWG ring terminals accommodate wire sizes from 12 AWG (largest) to 10 AWG (smallest). Never force larger wire into smaller terminals or use undersized terminals on heavy-gauge wire.

How tight should ring terminal connections be torqued?

Follow manufacturer specifications, typically 20-25 inch-pounds for small terminals and up to 250 inch-pounds for large industrial terminals. Over-tightening can damage threads or crack insulation.

Are ring terminals required by electrical code?

While not specifically mandated, NEC Article 110.14 requires permanent connections for most electrical applications. Ring terminals provide the most reliable permanent connection method for screw-type terminals.

What’s the difference between vinyl and heat-shrink insulation?

Vinyl insulation provides basic protection and color coding. Heat-shrink insulation creates a moisture-proof seal when heated, making it essential for outdoor, marine, or high-humidity applications.

Can ring terminals be used in wet locations?

Standard vinyl-insulated terminals are not rated for wet locations. Use heat-shrink terminals with adhesive lining or marine-grade terminals specifically designed for moisture exposure.

What causes ring terminals to overheat?

Overheating typically results from loose connections, undersized terminals for the current load, or corroded contact surfaces. Always verify proper sizing and maintain tight connections per manufacturer specifications.

Quick Reference: Ring Terminal Selection Checklist

Before Purchase:

- ☐ Measure wire gauge accurately

- ☐ Determine mounting stud diameter

- ☐ Verify current rating requirements

- ☐ Check environmental conditions

- ☐ Confirm UL listing needs

During Installation:

- ☐ De-energize circuit completely

- ☐ Strip wire to proper length

- ☐ Use ratcheting crimp tool

- ☐ Perform pull test verification

- ☐ Torque connection to specification

After Installation:

- ☐ Verify secure mechanical connection

- ☐ Check for proper electrical continuity

- ☐ Document installation for future reference

- ☐ Schedule periodic inspection

Professional Recommendation: For electrical connections where safety and reliability are paramount, ring insulated terminals provide the highest level of connection security available. Always prioritize UL-listed, copper construction terminals for code compliance and long-term reliability. When in doubt about sizing or application requirements, consult with a qualified electrician to ensure proper installation and code compliance.