Cold-pressed terminals are chosen by matching three critical factors: wire diameter (AWG size), terminal material (copper or aluminum), and required current load capacity. The correct terminal must accommodate your specific wire gauge, handle the electrical load safely, and comply with electrical codes for your application.

Understanding how to select the right cold-pressed terminal prevents electrical failures, ensures code compliance, and creates reliable long-term connections in your electrical systems.

What Are Cold-Pressed Terminals?

Cold-pressed terminals, also called compression terminals or crimp terminals, are electrical connectors that create secure wire connections without heat or soldering. You install them by compressing the terminal onto the wire using specialized crimping tools, creating a gas-tight mechanical and electrical connection.

Key characteristics of cold-pressed terminals:

- Compression connection: Uses mechanical force to create the bond

- No heat required: Installation at room temperature prevents wire insulation damage

- Code compliant: UL Listed terminals meet NEC requirements when properly installed

- Permanent connection: Creates a reliable, long-lasting electrical joint

Cold-Pressed vs. Soldered vs. Mechanical Terminals Comparison

Here is a table that shows the key differences between terminal connection types:

| Feature | Cold-Pressed | Soldered | Mechanical (Screw) |

|---|---|---|---|

| Installation Speed | Fast (30 seconds) | Slow (3-5 minutes) | Moderate (1-2 minutes) |

| Heat Required | None | High (400-500°F) | None |

| Code Compliance | UL Listed when proper | Requires special approval | Limited applications |

| Reliability | Excellent | Good | Fair |

| Removability | Not reusable | Not reusable | Reusable |

| Cost per Connection | $0.25-$2.50 | $0.10-$0.50 | $2.00-$15.00 |

| Corrosion Resistance | Excellent (with coating) | Good | Poor (exposed threads) |

| Vibration Resistance | Superior | Good | Fair |

Wire Diameter and Terminal Size Matching Guide

Expert Tip: Always verify wire diameter with a wire gauge tool before selecting terminals. Wire insulation thickness can make visual sizing unreliable.

Standard AWG to Terminal Size Conversion Table

| Wire Size (AWG) | Actual Diameter (inches) | Terminal Barrel Size | Max Current (75°C) | Typical Applications |

|---|---|---|---|---|

| 14 AWG | 0.064″ | #14 | 20A | Household circuits, lighting |

| 12 AWG | 0.081″ | #12 | 25A | General outlets, small appliances |

| 10 AWG | 0.102″ | #10 | 35A | Electric dryers, air conditioners |

| 8 AWG | 0.128″ | #8 | 50A | Electric ranges, large motors |

| 6 AWG | 0.162″ | #6 | 65A | Sub-panels, electric vehicle charging |

| 4 AWG | 0.204″ | #4 | 85A | Service entrances, large equipment |

| 2 AWG | 0.258″ | #2 | 115A | Main panels, industrial equipment |

| 1/0 AWG | 0.325″ | 1/0 | 150A | Service conductors |

| 2/0 AWG | 0.365″ | 2/0 | 175A | Large service entrances |

| 4/0 AWG | 0.460″ | 4/0 | 230A | Industrial services |

Safety Warning: Using undersized terminals can cause overheating, arcing, and fire hazards. Always match or exceed the wire’s current rating.

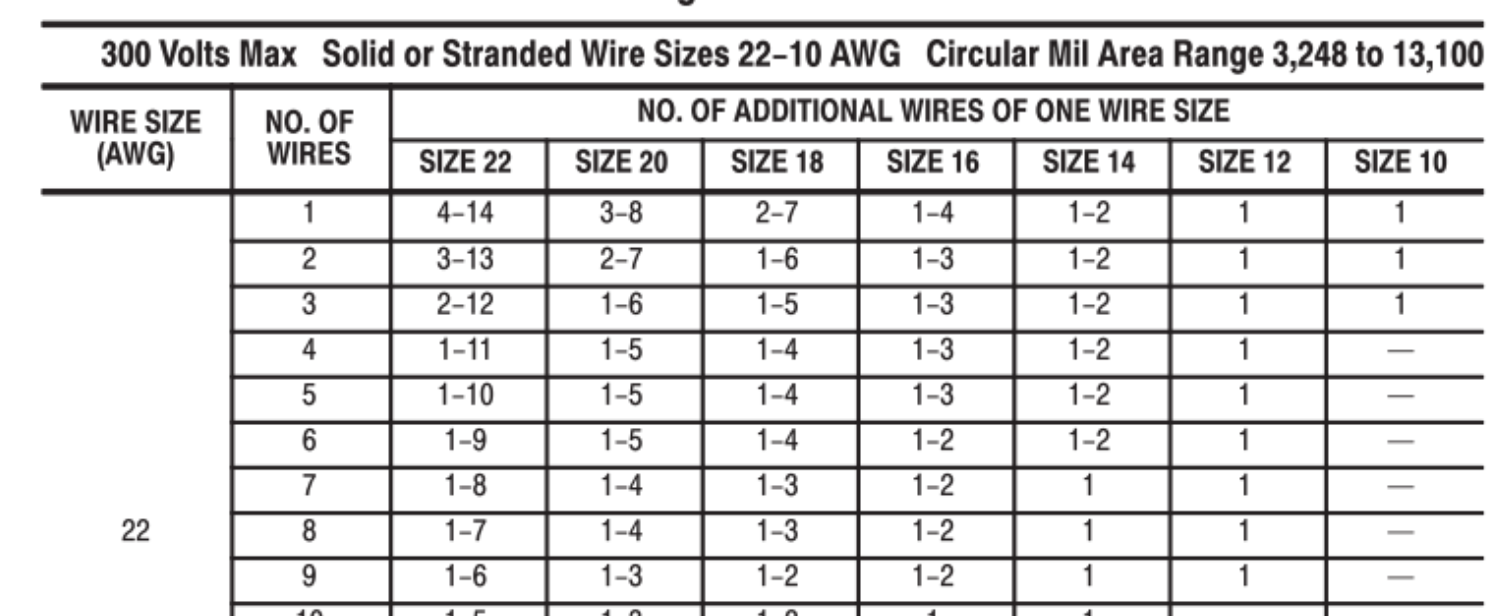

Multi-Conductor Wire Considerations

For multi-stranded wire, measure the total conductor area, not individual strand diameter:

- Fine strand wire (Class K): Requires terminals with larger barrel openings

- Extra fine strand (Class M): May need special flexible terminals

- Compact strand: Standard terminals typically accommodate these conductors

Terminal Material Selection Guide

Copper vs. Aluminum Terminal Comparison

Here is a table that shows the differences between terminal materials:

| Property | Copper Terminals | Aluminum Terminals | Bi-Metal Terminals |

|---|---|---|---|

| Conductivity | Excellent (100%) | Good (61% of copper) | Variable |

| Corrosion Resistance | Superior | Good (with coating) | Excellent |

| Cost | Higher ($0.50-$3.00) | Lower ($0.25-$1.50) | Highest ($1.00-$5.00) |

| Weight | Heavy | Light (30% of copper) | Medium |

| Expansion Rate | Low | Higher | Copper side low |

| Code Requirements | Universal approval | AL/CU rated required | Special applications |

| Galvanic Compatibility | Copper wire only | Aluminum wire only | Both materials |

Material Selection Decision Matrix

Choose Copper Terminals When:

- Connecting copper conductors (most common)

- Maximum conductivity is required

- Long-term reliability is critical

- Working in high-vibration environments

- Code requires copper-only connections

Choose Aluminum Terminals When:

- Connecting aluminum conductors

- Weight reduction is important

- Cost is a primary concern

- AL/CU rating is verified

- Proper anti-oxidant compound is used

Choose Bi-Metal Terminals When:

- Joining copper and aluminum conductors

- Preventing galvanic corrosion

- Transition connections are needed

- Code specifically requires bi-metal

Expert Tip: Never mix copper and aluminum conductors in standard terminals. Use only bi-metal or AL/CU rated terminals for dissimilar metal connections.

Current Load Capacity Analysis

Temperature-Corrected Current Ratings

Current capacity varies significantly with ambient temperature and conductor insulation type:

| Wire Size | 60°C Rating | 75°C Rating | 90°C Rating | Ambient Correction Factor |

|---|---|---|---|---|

| 12 AWG | 20A | 25A | 30A | 0.88 (40°C ambient) |

| 10 AWG | 30A | 35A | 40A | 0.82 (45°C ambient) |

| 8 AWG | 40A | 50A | 55A | 0.75 (50°C ambient) |

| 6 AWG | 55A | 65A | 75A | 0.67 (55°C ambient) |

| 4 AWG | 70A | 85A | 95A | 0.58 (60°C ambient) |

Safety Warning: High ambient temperatures significantly reduce current capacity. Apply temperature correction factors per NEC Table 310.15(B)(2)(a).

Derating Factors for Multiple Conductors

When multiple current-carrying conductors share the same conduit or cable tray:

- 4-6 conductors: Multiply capacity by 0.80

- 7-9 conductors: Multiply capacity by 0.70

- 10-20 conductors: Multiply capacity by 0.50

- 21-30 conductors: Multiply capacity by 0.45

Terminal Applications and Use Cases

Residential Applications

Panel Connections:

- Main service lugs: 4/0 AWG copper terminals

- Branch circuit breakers: 12-14 AWG terminals

- Ground and neutral bars: Appropriately sized terminals

Equipment Connections:

- HVAC units: 8-10 AWG terminals for condensers

- Electric water heaters: 10-12 AWG terminals

- Sub-panel feeders: Size per calculated load

Commercial and Industrial Applications

Motor Control Centers:

- Control wiring: 12-16 AWG terminals

- Power connections: 6-4/0 AWG terminals depending on motor size

- Ground connections: Equipment grounding conductor size

Transformer Connections:

- Primary connections: Based on transformer KVA rating

- Secondary connections: Calculated per load requirements

- Grounding: Per NEC Article 250 requirements

Expert Tip: Industrial applications often require terminals with additional certifications like UL 486A-B for aluminum conductors or special temperature ratings.

Step-by-Step Terminal Selection Process

Step 1: Determine Wire Specifications

- Measure actual wire diameter using a wire gauge tool

- Identify conductor material (copper or aluminum)

- Check insulation temperature rating (60°C, 75°C, or 90°C)

- Count current-carrying conductors in the circuit

Step 2: Calculate Required Current Capacity

- Determine circuit load in amperes

- Apply temperature correction factors if ambient exceeds 30°C (86°F)

- Apply derating factors for multiple conductors

- Add 25% safety margin for continuous loads

Step 3: Select Terminal Specifications

- Match terminal barrel size to wire diameter exactly

- Choose appropriate material (copper, aluminum, or bi-metal)

- Verify current rating meets or exceeds calculated requirements

- Confirm code compliance (UL Listed, appropriate certifications)

Step 4: Verify Compatibility and Safety

- Check terminal temperature rating matches conductor insulation

- Ensure proper crimping tool compatibility

- Verify installation torque requirements

- Confirm environmental ratings (indoor/outdoor, corrosive conditions)

Terminal Installation Safety Requirements

Code Compliance Checklist

NEC Requirements:

- ✓ Use only UL Listed terminals appropriate for the application

- ✓ Match terminal material to conductor material

- ✓ Apply proper installation torque values

- ✓ Use anti-oxidant compound on aluminum connections

- ✓ Maintain proper spacing and clearances

Safety Warning: Improper terminal installation is a leading cause of electrical fires. Always follow manufacturer specifications and local electrical codes.

Installation Best Practices

Pre-Installation:

- Verify power is OFF and locked out

- Clean conductor surfaces of oxidation

- Inspect terminals for cracks or damage

- Select proper crimping tools

During Installation:

- Strip conductor insulation to exact length

- Apply anti-oxidant compound (aluminum only)

- Center conductor in terminal barrel

- Apply manufacturer-specified crimp pressure

- Verify secure mechanical connection

Post-Installation:

- Inspect for proper conductor seating

- Check for damaged insulation

- Verify torque specifications

- Test connection resistance if required

Terminal Selection Decision Tree

For Standard Applications:

- Copper wire + Normal environment → Copper terminals

- Aluminum wire + Approved application → AL/CU rated terminals

- Mixed materials → Bi-metal terminals only

- High-vibration environment → Compression terminals with mechanical strain relief

For Special Conditions:

- Wet locations: Use terminals rated for wet conditions

- Corrosive environments: Select terminals with appropriate coatings

- High temperature: Verify terminal temperature rating exceeds ambient

- Underground applications: Use terminals rated for direct burial

Expert Tip: When in doubt, consult local electrical inspectors about terminal requirements for specific applications. Code interpretations can vary by jurisdiction.

Troubleshooting Common Terminal Problems

Connection Failures and Solutions

| Problem | Cause | Solution | Prevention |

|---|---|---|---|

| Overheating | Undersized terminal | Replace with proper size | Verify current calculations |

| Corrosion | Material incompatibility | Use bi-metal terminals | Match materials properly |

| Loose connection | Improper crimp | Re-terminate connection | Use calibrated tools |

| Conductor pullout | Inadequate compression | Replace terminal | Follow crimp specifications |

| Insulation damage | Excessive strip length | Replace conductor | Strip to exact length |

Diagnostic Testing Methods

Visual Inspection:

- Check for discoloration or burn marks

- Verify proper conductor seating

- Look for cracked or damaged terminals

- Inspect for corrosion or oxidation

Electrical Testing:

- Measure connection resistance (should be <0.001 ohms)

- Verify voltage drop across connections

- Test insulation resistance to ground

- Check for proper continuity

Frequently Asked Questions

What makes cold-pressed terminals different from other connection methods?

Cold-pressed terminals create a permanent mechanical connection using compression force without heat. This prevents insulation damage and creates a gas-tight connection that’s more reliable than screw terminals and faster to install than soldered joints. They’re specifically designed to meet electrical code requirements for permanent installations.

How do you match wire diameter to terminal size accurately?

Use a wire gauge tool to measure the actual conductor diameter, not the overall cable diameter including insulation. Match this measurement to the terminal barrel specifications provided by the manufacturer. For stranded wire, ensure the terminal can accommodate the total conductor cross-sectional area, which may be larger than equivalent solid wire.

Can you use copper terminals on aluminum wire?

No, standard copper terminals should never be used on aluminum conductors due to galvanic corrosion and different expansion rates. Only use terminals specifically rated “AL/CU” or bi-metal terminals when connecting aluminum conductors. Apply anti-oxidant compound to aluminum connections as required by code.

What current capacity safety margin should you include?

Add a minimum 25% safety margin above the calculated load for continuous circuits (operating more than 3 hours continuously). For non-continuous loads, match the terminal rating to the wire’s ampacity after applying temperature and bundling corrections. Industrial applications may require larger safety margins.

How do ambient temperature and multiple conductors affect terminal selection?

High ambient temperatures reduce current capacity – apply correction factors from NEC Table 310.15(B)(2)(a). Multiple current-carrying conductors in the same conduit require derating factors: 80% for 4-6 conductors, 70% for 7-9 conductors. Calculate these corrections before selecting terminal sizes.

What are the most common terminal installation mistakes?

The most frequent errors include: mismatching terminal material to conductor material, using undersized terminals for the current load, improper conductor stripping length, inadequate crimping pressure, and failing to apply anti-oxidant compound on aluminum connections. Always verify specifications before installation.

When should you use bi-metal terminals instead of standard terminals?

Use bi-metal terminals when connecting different conductor materials (copper to aluminum), in corrosive environments where dissimilar metals might be present, or when code specifically requires them. They prevent galvanic corrosion and accommodate different expansion rates between materials.

How do you verify proper terminal installation quality?

Perform both visual and electrical verification: check for proper conductor seating in the terminal barrel, verify no damaged insulation, measure connection resistance (should be <0.001 ohms), and ensure the conductor cannot be pulled from the terminal with reasonable force. Document installations for code compliance records.

Expert Selection Recommendations

Terminal Quality Indicators

Look for these certifications:

- UL Listed (required for most applications)

- CSA certified for Canadian installations

- RoHS compliant for environmental requirements

- IEEE 835 tested for nuclear applications

Quality construction features:

- Seamless barrel construction

- Proper conductor entry chamfers

- Corrosion-resistant plating

- Clear size markings and ratings

Manufacturer and Supplier Considerations

Choose terminals from established manufacturers with comprehensive testing and certification. Verify that terminals meet local electrical code requirements and are appropriate for your specific application environment.

Bulk purchasing considerations:

- Standard sizes (12-6 AWG) for general electrical work

- Mixed material compatibility for diverse projects

- Proper storage to prevent corrosion

- Documentation for inspection and code compliance

Expert Tip: Maintain a selection of common terminal sizes and materials on hand, but always verify specific requirements for each project. Electrical codes and load calculations take precedence over convenience.

Professional Recommendation: For complex electrical installations or when local code interpretations are unclear, consult with a licensed electrician or electrical engineer. Proper terminal selection is critical for electrical safety and code compliance.