Wire connectors are essential electrical components that safely join two or more electrical wires together, creating secure connections that prevent electrical hazards while ensuring reliable power transmission. These small but critical devices are used across residential, commercial, industrial, and automotive applications to maintain electrical integrity and safety.

What Are Wire Connectors?

Wire connectors are UL Listed fasteners used to make a tight connection with little interference between two or more electrical wires in an electrical box. Made of flame-retardant materials, wire connectors prevent wires from contacting other wires or exposed metal surfaces, which could cause a dangerous fault or short circuit.

The basic design consists of an insulating plastic or ceramic exterior housing with an internal metal spring or threading mechanism that securely grips the stripped wire ends when twisted together.

Primary Applications of Wire Connectors

Residential Electrical Systems

Wire connectors serve numerous critical functions in home electrical systems:

Lighting Applications:

- Light switches, receptacles, ceiling fans, can lights, thermostat controls

- Recessed lighting installations

- Chandelier and fixture connections

- Under-cabinet lighting systems

Safety and Security Systems:

- HVAC, smoke/CO detectors, garage doors, doorbells, security systems

- Motion sensor connections

- Alarm system wiring

- Doorbell and intercom installations

Power Distribution:

- Junction box connections

- Outlet and receptacle wiring

- Circuit breaker panel connections

- Electrical panel upgrades

Commercial and Industrial Applications

Terminal blocks are essential for connecting control wires in industrial control panels, facilitating easy maintenance and troubleshooting.

Industrial Control Systems:

- Manufacturing equipment connections

- Motor control centers

- PLC (Programmable Logic Controller) wiring

- Control panel assemblies

Commercial Buildings:

- Office building electrical systems

- Retail store lighting and power

- Restaurant equipment connections

- Data center power distribution

Automotive Industry Applications

Crimp connectors and quick-connect connectors are extensively used in automotive wiring harnesses for connecting various electrical components.

Vehicle Electrical Systems:

- Engine management connections

- Lighting system wiring

- Audio system installations

- Dashboard component connections

- Trailer wiring harnesses

Outdoor and Underground Applications

Underground connectors or waterproof connectors are often found in sprinkler systems, outdoor pet containment systems, low-voltage outdoor lighting and similar applications.

Landscape and Outdoor Systems:

- Irrigation system controls

- Outdoor lighting installations

- Pool and spa electrical connections

- Security camera wiring

- Garden lighting systems

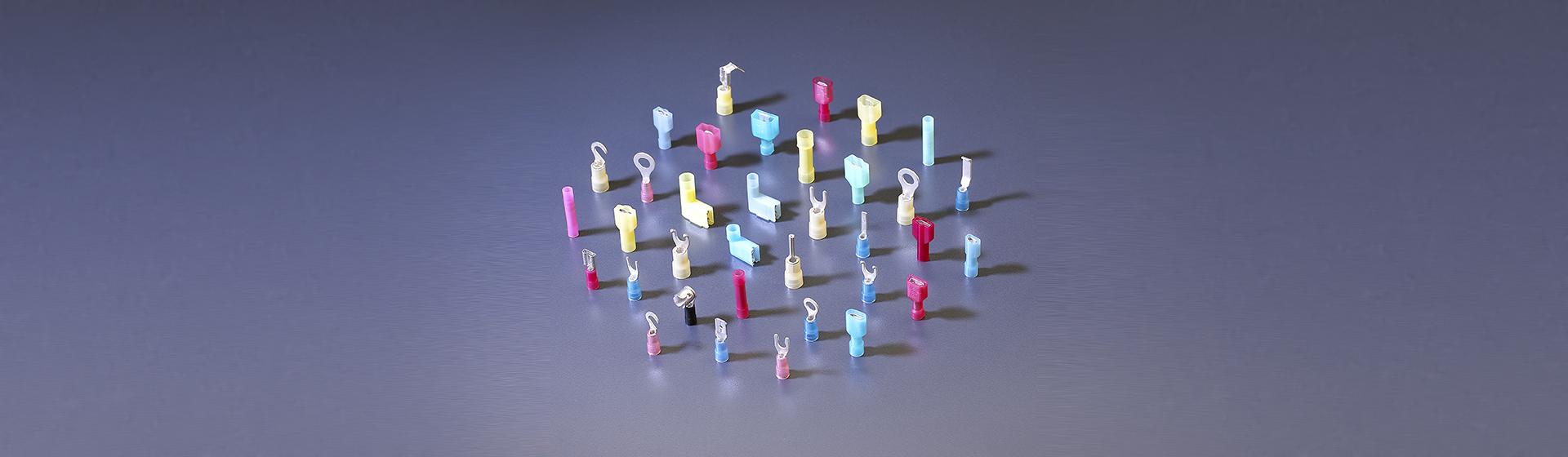

Types of Wire Connectors and Their Specific Uses

1. Twist-On Wire Connectors (Wire Nuts)

Twist-on wire connectors are widely used in North America and several European countries in residential, commercial and industrial building power wiring.

Best Applications:

- Interior residential wiring

- Junction box connections

- Light fixture installations

- General electrical repairs

Color-Coded Sizing:

- Gray: 22-16 AWG (2-3 wires)

- Blue: 16-14 AWG (2-3 wires)

- Orange: 14-12 AWG (2-4 wires)

- Yellow: 12-10 AWG (2-5 wires)

- Red: 10-8 AWG (2-6 wires)

2. Push-In Wire Connectors

Push-in wire connectors feature spring-loaded terminals that allow wires to be inserted directly into the connector without stripping the insulation, providing a quick and easy way to make connections, ideal for residential and commercial electrical installations.

Ideal Applications:

- Quick electrical repairs

- Temporary connections

- Lighting retrofits

- Small appliance wiring

3. Crimp Connectors

Crimp connectors are made of metal and crimped onto the stripped ends of wires using a crimping tool, providing a strong and durable connection suitable for automotive, marine, and aerospace applications.

Primary Uses:

- Automotive wiring harnesses

- Marine electrical systems

- Aerospace applications

- High-vibration environments

4. Waterproof and Underground Connectors

Weatherproof and waterproof wire connectors are specialized, single-use devices that contain a silicone sealant in the cap and protective fins or flanges covering the cap opening to protect the wiring from corrosion, dust and moisture.

Essential Applications:

- Outdoor electrical installations

- Underground cable connections

- Pool and spa systems

- Irrigation controls

- Marine environments

5. Terminal Blocks

Terminal blocks are used to connect multiple wires together in industrial and commercial applications, consisting of a strip of insulating material with metal terminals where wires can be inserted and secured using screws or clamps.

Commercial Applications:

- Industrial control panels

- Distribution boards

- Equipment control systems

- Building automation systems

Safety Standards and Code Compliance

UL Listing and Certification

All quality wire connectors should carry UL (Underwriters Laboratories) certification, ensuring they meet rigorous safety standards for electrical use. 3M™ Performance Plus™ Wire Connectors are UL Listed for 600 volts on copper wire, ensuring they meet the highest safety and performance standards.

Installation Safety Requirements

Proper Installation Practices:

- Always turn off power before making connections

- Strip wires to manufacturer specifications

- Ensure no bare copper extends beyond the connector

- Perform tug tests to verify secure connections

- Follow color-coding guidelines for proper sizing

Code Compliance Considerations

Wire connector installations must comply with:

- National Electrical Code (NEC) requirements

- Local building codes

- OSHA workplace safety standards

- International electrical standards (where applicable)

Specialized Wire Connector Applications

High-Temperature Environments

High-temperature wire nuts are designed to withstand heat and prevent melting or degradation in applications such as:

- Heating system connections

- Industrial furnace wiring

- High-wattage lighting fixtures

- Oven and appliance connections

Aluminum Wire Connections

Special considerations apply when working with aluminum wiring:

- Specific twist-on wire connectors containing a conductive, anti-oxidant gel are registered for use on residential aluminum wiring in Canada

- Purple-colored connectors designed for aluminum-to-copper connections

- Anti-oxidant compounds prevent corrosion

Data and Telecommunications

Modern wire connectors also serve in low-voltage applications:

- Network cable terminations

- Telephone system connections

- Security system wiring

- Audio/visual equipment installations

Selection Criteria for Wire Connectors

Wire Gauge Compatibility

Choose connectors based on:

- American Wire Gauge (AWG) requirements

- Number of wires being connected

- Solid vs. stranded wire considerations

- Current-carrying capacity needs

Environmental Factors

Consider these conditions:

- Indoor vs. outdoor installation

- Moisture exposure potential

- Temperature ranges

- Vibration and movement

- Chemical exposure risks

Application-Specific Requirements

Match connector type to use:

- Permanent vs. temporary connections

- Accessibility for future maintenance

- Code compliance requirements

- Cost and availability factors

Installation Best Practices

Preparation Steps

- Power Safety: Always turn off power at the breaker

- Wire Stripping: Remove insulation per manufacturer specs

- Wire Alignment: Ensure flush, even wire ends

- Connector Selection: Choose appropriate size and type

Installation Process

- Twist Wires: Pre-twist wire ends if required

- Apply Connector: Twist clockwise until snug

- Visual Inspection: Verify no exposed copper

- Tug Test: Gently pull to confirm secure connection

- Power Restoration: Test circuit functionality

Quality Assurance

Post-installation checks should include:

- Visual inspection for proper coverage

- Electrical testing with appropriate meters

- Thermal imaging for hot spots (in commercial applications)

- Documentation for maintenance records

Common Mistakes to Avoid

Sizing Errors

- Using undersized connectors that don’t fully cover wires

- Selecting oversized connectors that don’t grip properly

- Mixing different wire gauges in single connectors

Installation Problems

- Insufficient wire stripping length

- Over-tightening causing damage

- Reusing single-use connectors

- Ignoring manufacturer torque specifications

Safety Oversights

- Working on live circuits

- Failing to verify secure connections

- Using non-UL listed products

- Ignoring environmental requirements

Maintenance and Inspection

Regular Inspection Schedule

Establish routine checks for:

- Visual signs of overheating or damage

- Loose connections causing intermittent power

- Corrosion in outdoor applications

- Compliance with updated code requirements

Warning Signs

Watch for these indicators of connector problems:

- Flickering lights or intermittent power

- Burning smells or visible damage

- Hot spots detected during thermal scans

- Loose connections during maintenance

Future Trends in Wire Connector Technology

Smart Building Integration

Modern connector applications include:

- IoT device connections

- Smart home automation systems

- Energy monitoring equipment

- Advanced HVAC controls

Sustainable Solutions

Environmental considerations drive:

- Recyclable connector materials

- Lead-free construction

- Energy-efficient designs

- Reduced packaging waste

Conclusion

Wire connectors play an indispensable role in electrical systems across residential, commercial, industrial, and automotive applications. From simple household wiring projects to complex industrial control systems, these essential components ensure safe, reliable electrical connections that meet stringent safety standards.

Understanding the specific applications and proper selection criteria for different types of wire connectors helps ensure electrical integrity, safety compliance, and long-term reliability. Whether you’re a DIY homeowner, professional electrician, or facility manager, choosing the right wire connector for each application is crucial for maintaining safe and efficient electrical systems.

For complex electrical projects or when in doubt about proper connector selection, always consult with a qualified electrician to ensure code compliance and safety standards are met.