A quick disconnect serves one primary purpose: to enable rapid, safe connection and disconnection of fluid, electrical, or pneumatic systems without tools. These mechanical coupling devices allow you to join or separate system components in seconds while maintaining leak-proof seals and preventing contamination, downtime, or safety hazards during equipment maintenance, testing, or reconfiguration.

Quick disconnects eliminate the time-consuming process of threading, clamping, or bolting connections, making them essential for applications requiring frequent system changes, emergency shutoffs, or routine maintenance access.

Quick Disconnect Definitions: Understanding the Basics

What is a Quick Disconnect?

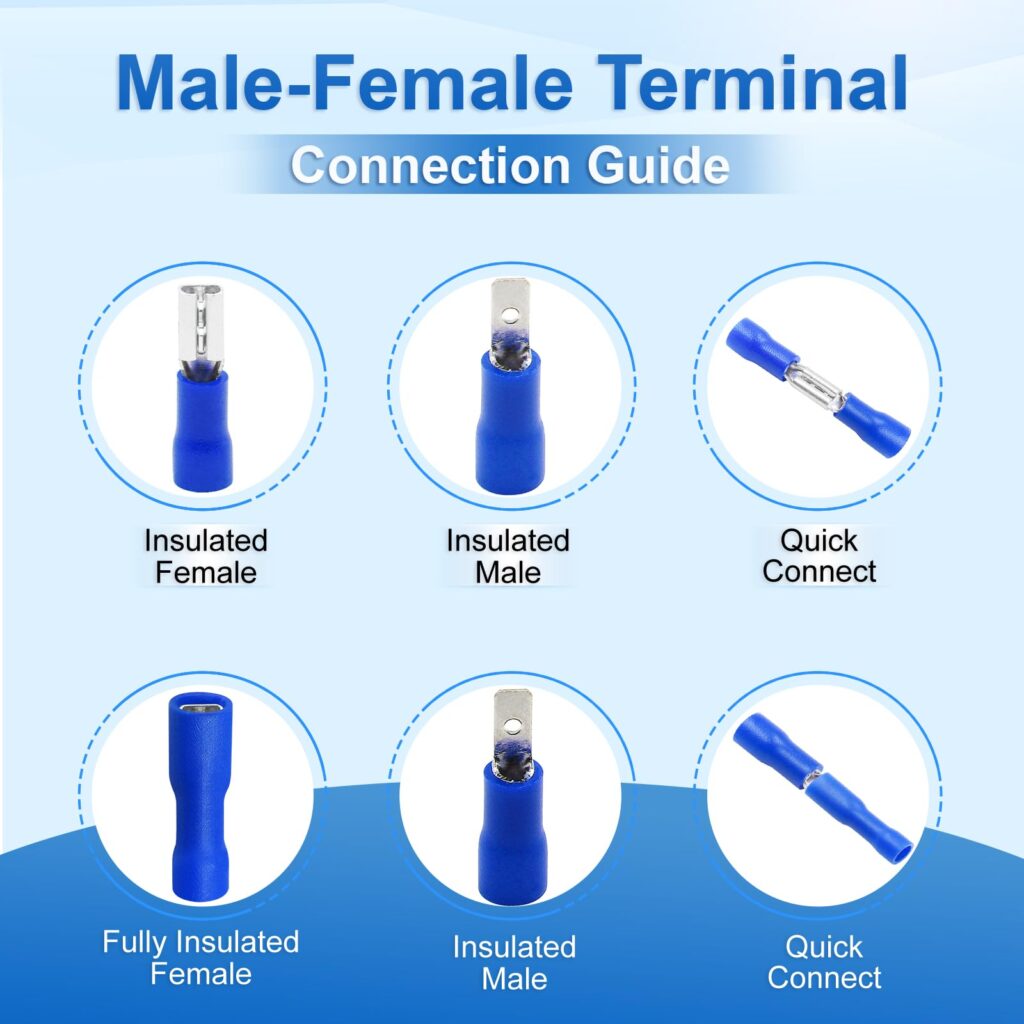

A quick disconnect (also called a quick connect, quick coupling, or rapid coupling) is a two-part mechanical fitting that allows instant connection and disconnection of lines carrying fluids, gases, or electrical signals. The system consists of a plug (male end) and socket (female end) that lock together with a simple push-and-click or twist motion.

How Quick Disconnects Work

Quick disconnects use internal mechanisms like ball bearings, spring-loaded sleeves, or cam levers to create secure, sealed connections. When you push the plug into the socket, internal components automatically engage to form a leak-tight seal. To disconnect, you simply pull back a sleeve, press a button, or twist the coupling to release the connection.

Key Differences: Quick Disconnect vs Traditional Connections

Here is a table that shows the fundamental differences between quick disconnects and traditional connection methods:

| Feature | Quick Disconnect | Traditional Connection | Advantage |

|---|---|---|---|

| Connection Time | 2-5 seconds | 2-15 minutes | 95% faster installation |

| Tools Required | None | Wrenches, screwdrivers | Reduced labor costs |

| Seal Quality | Automatic O-ring seal | Manual torque-dependent | More reliable sealing |

| Disconnection Speed | Instant release | 2-15 minutes | Emergency shutdown capability |

| Contamination Risk | Built-in shutoff valves | Open system during changes | Cleaner fluid handling |

| Maintenance Access | Quick component removal | Extended downtime | Reduced service time |

| User Training | Minimal instruction | Technical expertise | Lower skill requirements |

| Reusability | Thousands of cycles | Limited by wear | Long-term cost savings |

Primary Purposes of Quick Disconnects

1. Maintenance and Service Access

Quick disconnects allow technicians to rapidly disconnect equipment for maintenance without draining entire systems or losing system pressure. This purpose is critical in:

- Hydraulic systems: Quick removal of cylinders, motors, or valves

- Compressed air lines: Instant tool changes without system depressurization

- Cooling systems: Fast radiator or heat exchanger service

- Chemical processing: Safe component isolation for cleaning or replacement

2. Equipment Reconfiguration

Manufacturing and testing environments use quick disconnects to rapidly reconfigure systems for different products or test scenarios. You can:

- Switch between different test fixtures in seconds

- Change tooling on automated equipment instantly

- Redirect fluid flows without system shutdown

- Modify electrical connections for different configurations

3. Emergency System Isolation

Quick disconnects provide immediate system isolation during emergencies, preventing:

- Fluid spills from damaged equipment

- Pressure buildup in malfunctioning components

- Electrical hazards through instant circuit disconnection

- Fire spread via automatic fuel line shutoff

4. Contamination Prevention

Built-in shutoff valves in quick disconnects automatically seal both connection points when disconnected, preventing:

- Dirt and debris entry into hydraulic systems

- Moisture infiltration in pneumatic lines

- Chemical cross-contamination in process equipment

- System pressure loss during line changes

Applications and Use Cases

Industrial Manufacturing

- Assembly lines: Rapid tooling changes between product runs

- Hydraulic presses: Quick die changes without system drainage

- Pneumatic automation: Instant actuator reconfiguration

- Coolant systems: Fast spindle or tool coolant connections

Automotive and Transportation

- Vehicle testing: Quick connection of diagnostic equipment

- Fleet maintenance: Rapid hydraulic system service

- Racing applications: Fast fuel line and cooling system changes

- Heavy equipment: Quick implement attachment and removal

Laboratory and Medical

- Analytical instruments: Contamination-free sample line changes

- Medical devices: Sterile fluid path connections

- Research equipment: Quick test setup modifications

- Chemical analysis: Safe reagent line switching

HVAC and Plumbing

- System testing: Rapid pressure test equipment connection

- Component replacement: Quick valve or filter changes

- Seasonal equipment: Fast pool or irrigation system connections

- Maintenance access: Instant isolation of system components

Quick Disconnect Types and Selection Guide

Here is a table comparing the main types of quick disconnects and their optimal applications:

| Type | Operating Pressure | Temperature Range | Best Applications | Key Benefits |

|---|---|---|---|---|

| Hydraulic | 3,000-10,000 PSI | -40°F to 250°F | Heavy machinery, industrial equipment | High pressure capability, robust construction |

| Pneumatic | 150-300 PSI | -40°F to 200°F | Air tools, automation systems | Fast cycling, lightweight design |

| Water/Coolant | 150-500 PSI | 32°F to 180°F | Cooling systems, washdown applications | Corrosion resistance, easy operation |

| Chemical | 150-3,000 PSI | -20°F to 400°F | Process equipment, laboratories | Chemical compatibility, leak-tight sealing |

| Electrical | N/A (voltage rated) | -40°F to 300°F | Control systems, testing equipment | Signal integrity, EMI shielding |

Selection Criteria for Quick Disconnects

What should you look for when choosing quick disconnects?

- Pressure Rating: Must exceed maximum system pressure by 25% safety factor

- Flow Requirements: Coupling size should not restrict required flow rates

- Fluid Compatibility: Materials must resist chemical attack from system fluids

- Temperature Range: Operating temperatures must stay within coupling specifications

- Connection Frequency: Choose couplings rated for expected duty cycles

- Safety Features: Consider automatic shutoff valves and pressure relief options

💡 Expert Tip: Always select quick disconnects with a pressure rating at least 1.5 times your maximum system pressure to account for pressure spikes and provide a safety margin.

Installation and Safety Guidelines

Proper Installation Steps

How to install quick disconnects safely:

- System Preparation

- Shut off system pressure and drain lines completely

- Clean connection points of dirt, debris, and old sealant

- Inspect threads and sealing surfaces for damage

- Component Installation

- Install male and female halves according to flow direction arrows

- Apply thread sealant only to male threads (never female)

- Torque to manufacturer specifications using backup wrenches

- System Testing

- Gradually increase system pressure while checking for leaks

- Test connection and disconnection operation under pressure

- Verify automatic shutoff valve operation if equipped

- Final Verification

- Document installation location and coupling specifications

- Train operators on proper connection and disconnection procedures

- Establish inspection schedule for wear and damage assessment

Critical Safety Warnings

⚠️ SAFETY WARNING: Never disconnect quick connects under full system pressure. Always relieve pressure before disconnection to prevent injury from high-pressure fluid injection or whipping hoses.

⚠️ SAFETY WARNING: Use only couplings rated for your specific fluid type. Incompatible materials can fail catastrophically, causing equipment damage and serious injury.

⚠️ SAFETY WARNING: Always wear safety glasses and protective clothing when working with quick disconnects carrying pressurized fluids or hazardous chemicals.

Troubleshooting Common Quick Disconnect Problems

Connection Issues

Problem: Difficulty connecting or coupling won’t engage

- Cause: Debris in coupling mechanism or worn components

- Solution: Clean coupling thoroughly and inspect for wear

- Prevention: Implement regular cleaning schedule and protective caps

Leakage Problems

Problem: Fluid leaking from connection point

- Cause: Worn O-rings, improper connection, or pressure exceeding rating

- Solution: Replace seals, verify proper engagement, check system pressure

- Prevention: Use couplings within pressure ratings and replace seals preventively

Sticking or Hard Operation

Problem: Sleeve won’t move freely or coupling sticks

- Cause: Contamination, corrosion, or inadequate lubrication

- Solution: Disassemble, clean, lubricate, and reassemble coupling

- Prevention: Use filtered fluids and appropriate coupling materials

Quick Disconnect Specifications and Standards

Industry Standards and Certifications

Quick disconnects must comply with various industry standards depending on application:

- ISO 16028: International standard for hydraulic quick-acting couplings

- ISO 14541: Pneumatic fluid power quick-acting couplings

- ASME B31.3: Process piping requirements for chemical applications

- FDA CFR 21: Food and pharmaceutical grade material requirements

- UL Listed: Electrical quick disconnects for safety compliance

Professional Installation Requirements

Many applications require professional installation and inspection:

- Hydraulic systems over 3,000 PSI: Certified hydraulic technician

- Chemical process equipment: Licensed process engineer approval

- Medical device applications: FDA registered facility installation

- Electrical connections over 50V: Licensed electrician installation

Cost-Benefit Analysis of Quick Disconnects

Initial Investment vs Long-Term Savings

Here is a table showing the cost comparison between quick disconnects and traditional connections:

| Factor | Quick Disconnect | Traditional Connection | Savings with Quick Disconnect |

|---|---|---|---|

| Initial Cost per Connection | $25-200 | $5-50 | Higher upfront investment |

| Installation Labor | 5 minutes | 30-60 minutes | 85-90% labor reduction |

| Maintenance Downtime | 2-5 minutes | 30-120 minutes | 90-95% downtime reduction |

| Annual Maintenance Cycles | Same | Same | No difference |

| 5-Year Total Cost | Lower | Higher | 40-60% total savings |

💡 Expert Tip: Calculate your return on investment by multiplying labor rate times downtime saved per maintenance event, then multiply by annual maintenance frequency. Quick disconnects typically pay for themselves within 6-12 months in high-maintenance applications.

Frequently Asked Questions

What makes quick disconnects different from regular pipe fittings?

Quick disconnects feature built-in automatic sealing mechanisms and require no tools for connection or disconnection, while regular pipe fittings need threading, soldering, or mechanical compression with tools.

How many times can you connect and disconnect a quick coupling?

High-quality quick disconnects are rated for 5,000 to 50,000+ connection cycles depending on design and application. Industrial hydraulic couplings typically handle 10,000+ cycles before requiring maintenance.

Can quick disconnects handle high-pressure applications?

Yes, specialized hydraulic quick disconnects are rated for pressures up to 10,000 PSI or higher. Always verify the pressure rating matches or exceeds your system requirements with appropriate safety factor.

Do quick disconnects work with all types of fluids?

No, you must select couplings with seals and body materials compatible with your specific fluid. Chemical compatibility charts from manufacturers specify approved fluid types for each coupling design.

What safety features should you look for in quick disconnects?

Key safety features include automatic shutoff valves that prevent spills when disconnected, pressure relief mechanisms, and visual/audible connection confirmation to ensure proper engagement.

How do you maintain quick disconnects for maximum life?

Regular maintenance includes cleaning debris from coupling surfaces, replacing O-rings according to manufacturer schedules, lubricating moving parts with compatible lubricants, and inspecting for wear or damage.

Can you repair quick disconnects or must you replace them?

Most quality quick disconnects offer repair kits with replacement seals and wear components. However, body damage or excessive wear typically requires complete replacement for safety and performance.

What’s the difference between flat-face and poppet-style quick disconnects?

Flat-face couplings minimize fluid loss and contamination during disconnection but may have higher pressure drop, while poppet-style designs offer better flow characteristics but may drip slightly when disconnected.

Professional Recommendations and Next Steps

When to Consult Professionals

You should consult a qualified engineer or technician when:

- System pressures exceed 1,000 PSI in hydraulic applications

- Working with hazardous or toxic chemicals

- Installing electrical quick disconnects in critical safety systems

- Designing custom coupling solutions for specialized applications

- Troubleshooting repeated coupling failures or performance issues

Implementation Strategy

To successfully implement quick disconnects in your systems:

- Audit existing connections that require frequent access or cause extended downtime

- Calculate potential savings from reduced labor and downtime costs

- Select appropriate coupling types based on pressure, flow, and fluid requirements

- Train maintenance staff on proper connection, disconnection, and safety procedures

- Establish inspection schedules to maximize coupling life and prevent failures

Quick disconnects transform system maintenance from time-consuming, messy procedures into quick, clean operations that improve safety, reduce costs, and increase equipment availability. By choosing the right coupling type for your application and following proper installation and maintenance procedures, you’ll achieve significant operational improvements and long-term cost savings.

Ready to upgrade your systems with quick disconnects? Consult with a qualified fluid power specialist to identify the best coupling solutions for your specific applications and ensure safe, reliable operation for years to come.