What Are Wire Connectors and Why Do They Matter?

Wire connectors are devices designed to mechanically and electrically join electrical conductors. They create secure connections that maintain electrical continuity while protecting against environmental factors, vibration, and accidental disconnection. Proper connector selection is critical for electrical safety, code compliance, and system reliability.

Key Connector Components:

- Contact mechanism: Metal components that create electrical connection

- Housing: Protective shell that insulates and secures the connection

- Strain relief: Features that prevent wire damage from pulling or bending

- Sealing elements: Gaskets or boots that protect against moisture and contaminants

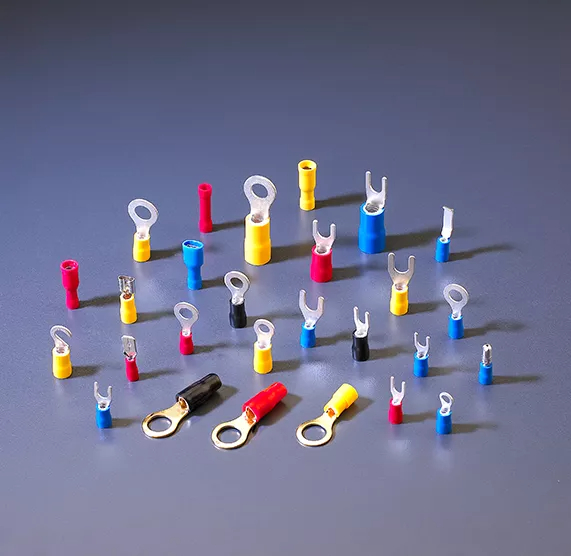

Types of Wire Connectors: Complete Comparison

Here is a table that shows the main categories of wire connectors and their primary applications:

| Connector Type | Best Applications | Voltage Range | Current Capacity | Key Advantages |

|---|---|---|---|---|

| Wire Nuts | Residential wiring, junction boxes | 600V max | 1-30A | Easy installation, code-approved, reusable |

| Terminal Blocks | Control panels, industrial wiring | 24V-1000V | 1-100A+ | Organized connections, test points, high current |

| Push-In Connectors | Quick connections, maintenance | 300V-600V | 12-32A | Tool-free installation, compact size |

| Crimp Connectors | Automotive, marine, outdoor | 12V-600V | 1-200A+ | Vibration resistant, weatherproof options |

| Lever Nuts | Reusable connections, mixed wire types | 600V max | 10-32A | Easy disconnection, solid/stranded mix |

Wire Connector Selection Criteria

1. Electrical Specifications

Voltage Rating: Choose connectors rated at least 125% of your system voltage

- Low voltage (12-24V): Automotive, LED, control circuits

- Standard voltage (120-240V): Residential and light commercial

- High voltage (480V+): Industrial and commercial applications

Current Capacity: Select connectors rated 125% above maximum expected current

- Light duty (1-15A): Residential lighting, outlets

- Medium duty (15-50A): Appliances, HVAC equipment

- Heavy duty (50A+): Industrial equipment, main feeders

2. Wire Compatibility Requirements

Wire Gauge Range: Ensure connector accommodates your wire sizes

- Small connectors: 18-12 AWG (typical residential)

- Medium connectors: 12-6 AWG (appliance circuits)

- Large connectors: 6 AWG and larger (service entrances)

Wire Type Compatibility:

- Solid wire: Single metal conductor

- Stranded wire: Multiple small conductors bundled together

- Mixed applications: Some connectors handle both types

3. Environmental Considerations

| Environment Type | Required Features | Recommended Connector Types |

|---|---|---|

| Indoor/Dry | Basic insulation, UL listing | Wire nuts, terminal blocks, lever nuts |

| Outdoor/Wet | Weather sealing, corrosion resistance | Sealed crimp connectors, gel-filled |

| Underground | Moisture protection, direct burial rating | Direct burial splice kits |

| Marine/Coastal | Salt spray resistance, sealed housing | Tinned copper crimp connectors |

| Industrial | Vibration resistance, high temperature | Crimp terminals, industrial terminal blocks |

Step-by-Step Connector Selection Process

Step 1: Determine Electrical Requirements

- Identify circuit voltage (12V, 120V, 240V, 480V, etc.)

- Calculate maximum current draw including 125% safety factor

- Note any special requirements (switching, fusing, etc.)

Step 2: Assess Wire Specifications

- Measure wire gauge (AWG) for all conductors

- Identify wire type (solid, stranded, or mixed)

- Count total number of wires to be connected

Step 3: Evaluate Environmental Conditions

- Determine installation location (indoor, outdoor, underground)

- Assess exposure to moisture, chemicals, or temperature extremes

- Consider vibration, movement, or mechanical stress factors

Step 4: Check Code Compliance

- Verify connector is UL listed for your application

- Confirm compliance with NEC (National Electrical Code)

- Check local code requirements and inspector preferences

Step 5: Select Appropriate Connector Type

- Match connector specifications to your requirements

- Choose connector type based on installation method preference

- Consider future maintenance and accessibility needs

Common Wire Connector Applications

Residential Applications

Junction Box Connections: Wire nuts are the standard choice for splicing wires in electrical boxes. They’re code-approved, reusable, and available in multiple sizes.

Light Fixture Installation: Push-in connectors or wire nuts work well for connecting fixtures to house wiring, with push-in types offering faster installation.

Outlet and Switch Wiring: Terminal blocks or push-in connectors provide secure connections for outlets and switches, especially in retrofit situations.

Commercial and Industrial Applications

Control Panel Wiring: Terminal blocks offer organized, testable connections with clear wire identification and easy troubleshooting access.

Motor Connections: Crimp connectors with heat shrink provide vibration-resistant connections that withstand industrial environments.

Outdoor Equipment: Sealed connectors with gaskets protect against moisture infiltration in outdoor lighting and equipment connections.

Safety Requirements and Code Compliance

⚠️ Critical Safety Warnings

Electrical Shock Prevention:

- Always turn off power at the breaker before making connections

- Use a non-contact voltage tester to verify power is off

- Never work on live circuits without proper training and equipment

Fire Prevention Requirements:

- Use only UL-listed connectors appropriate for your application

- Ensure connector current rating exceeds circuit requirements by 125%

- Avoid overtightening connections that could damage wires or connectors

National Electrical Code (NEC) Requirements

Section 110.14: Electrical connections must be made with listed devices appropriate for the conductor material, size, and application.

Section 300.15: Connections must be accessible for inspection and maintenance unless specifically exempted.

Article 760: Low-voltage circuits require appropriate connector types based on circuit classification and fire safety requirements.

Expert Tips for Connector Selection

💡 Professional Installation Tips

Wire Preparation: Strip wire to exact length specified by connector manufacturer. Too much exposed wire creates shock hazards; too little wire reduces connection reliability.

Connector Sizing: Choose the smallest connector that accommodates all wires. Oversized connectors may not grip wires properly, leading to loose connections.

Environmental Protection: In questionable environments, always err on the side of better protection. Moisture damage is expensive to repair and creates safety hazards.

🔧 Maintenance Considerations

Accessibility Planning: Install connectors in accessible locations whenever possible. Consider future maintenance needs during initial installation.

Connection Testing: Test all connections with appropriate meters before energizing circuits. High-resistance connections cause heat buildup and eventual failure.

Periodic Inspection: Schedule regular inspection of critical connections, especially in harsh environments or high-vibration applications.

Troubleshooting Common Connector Problems

Loose Connections

- Symptoms: Flickering lights, intermittent operation, warm connectors

- Causes: Undersized connectors, damaged wire strands, improper installation

- Solutions: Re-terminate with proper connector size, replace damaged wire

Overheating Issues

- Symptoms: Discolored connectors, burning smell, tripped breakers

- Causes: Undersized connectors, loose connections, overloaded circuits

- Solutions: Upgrade to higher-rated connectors, verify circuit loading

Moisture Infiltration

- Symptoms: Corrosion, ground faults, intermittent operation

- Causes: Inadequate sealing, wrong connector type for environment

- Solutions: Use weather-sealed connectors, apply appropriate sealants

When to Call a Professional

Consult a licensed electrician for:

- High-voltage applications (480V and above)

- Main service entrance connections

- Connections requiring special permits or inspections

- Any work where you’re uncertain about code requirements

Wire Connector Selection Quick Reference

Residential Projects (120V-240V)

- Standard splicing: Wire nuts (yellow, red, blue sizes)

- Quick connections: Push-in connectors or lever nuts

- Outdoor boxes: Weather-resistant wire nuts with sealing compound

Low-Voltage Applications (12V-24V)

- Automotive: Crimp connectors with heat shrink

- LED lighting: Push-in connectors or terminal blocks

- Control circuits: Terminal blocks with test points

Industrial Applications (480V+)

- Motor connections: Compression lugs with insulating boots

- Panel wiring: Terminal blocks with finger-safe barriers

- Outdoor equipment: NEMA-rated sealed connectors

Frequently Asked Questions

Q: What makes wire nuts different from other connector types?

A: Wire nuts use a threaded metal insert that twists onto stripped wires, creating both mechanical and electrical connection. They’re specifically designed for solid copper wire and are the most common residential connector type.

Q: Can you mix different wire types in the same connector?

A: Some connectors like lever nuts and certain push-in types can accommodate both solid and stranded wire. Always check manufacturer specifications to confirm compatibility before mixing wire types.

Q: How do you determine the right wire nut size?

A: Wire nut sizing depends on the total number and gauge of wires being connected. Manufacturers provide charts showing the range of wire combinations each size accommodates. Choose the smallest nut that fits your wire combination.

Q: What voltage rating should you choose for residential applications?

A: For standard residential wiring (120V-240V circuits), choose connectors rated for at least 600V. This provides adequate safety margin and ensures code compliance for all typical household applications.

Q: Are push-in connectors as reliable as wire nuts?

A: Quality push-in connectors from reputable manufacturers provide reliable connections when used within their specifications. They’re particularly useful for temporary connections or situations requiring frequent disconnection.

Q: What safety certifications should you look for?

A: Look for UL (Underwriters Laboratories) listing marks on all connectors. For special applications, additional certifications like CSA (Canadian Standards Association) or NEMA ratings may be required.

Q: How often should electrical connections be inspected?

A: Residential connections typically don’t require regular inspection unless problems arise. Industrial and commercial installations should follow maintenance schedules based on environmental conditions and equipment criticality.

Q: Can outdoor connectors be used indoors?

A: Yes, outdoor-rated connectors can be used indoors, but they’re typically more expensive and bulkier than necessary. Indoor connectors should never be used in outdoor applications due to inadequate environmental protection.

Conclusion: Making the Right Choice

Selecting the appropriate wire connector requires careful consideration of electrical specifications, environmental conditions, and code requirements. Start with your electrical requirements (voltage and current), confirm wire compatibility, then choose the connector type that best matches your installation environment and maintenance needs.

For standard residential applications, UL-listed wire nuts remain the preferred choice due to their proven reliability and code acceptance. Industrial and harsh environment applications benefit from terminal blocks or sealed crimp connectors that provide superior environmental protection and maintenance access.

Remember: when in doubt, consult with a licensed electrician. Proper connector selection and installation are critical for electrical safety, code compliance, and long-term system reliability. The small additional cost of premium connectors is always worthwhile compared to the risks and costs of connection failures.