Solder Seal Heat Shrink Butt Connector

The Solder Butts are made of superior hot melt adhesive material,which will melt the rich adhesives and wrap the solder wire connectors to apply in marine.

Send your requirements, we will quote for you within 12 hours

Tel:+8613655777486

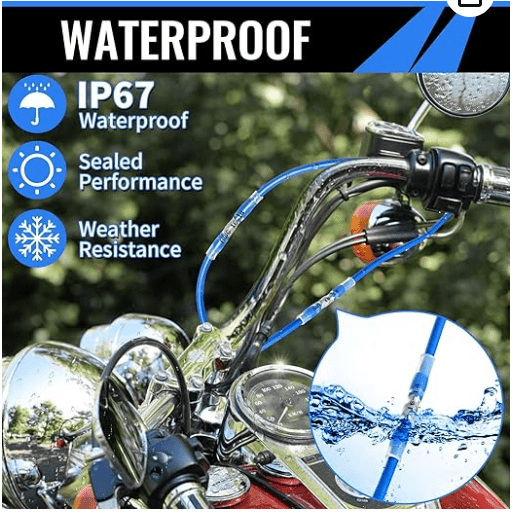

- The Waterproof wire connectors are made of superior hot melt adhesive material,which will melt the rich adhesives and wrap the solder wire connectors to apply in marine.

- Firm connection:High purity thick solder rings are an important part of our solder seal wire connectors,which forms rock-solid connections by the molten solder flowing and adhering completely after heating.

- With its EVA materials,the heat-shrink tube of solder seal wire connectors provide clear visibility of the soldering penetration and premium abrasion resistance for long-term reliability.

- Versatile:Our connectors can be used in a wide range of applications, including automotive, marine, and industrial applications, as well as home wiring and electronics projects.

- Good abrasion resistance and environmental protection, specially designed for harsh environments, to provide protection for wires and cables.

- Advanced solder seal ring, enough solder to melt and flow around the wire until a seal is formed on the wire, ensuring a lasting connection.

- Good weather resistance, the adhesive provided by the right amount of hot melt adhesive system, cools, hardens, and reaches the bonding strength within a few seconds, giving a lasting bond.

- In the case of preventing abrasion, cutting, abrasion and low impact, it creates a cable entry seal and provides environmental seal protection.

- Quick to operate, only a heat gun is needed to fix and connect the wires tightly.

Product Description

Specification: Item Type: Heat Shrink Tube Material: Nylon, tin Uses: Industrial production, electrical circuits Wiring Range: SST-S41 (yellow): 4-6mm² SST-S31 (blue): 1.5-2.5mm² SST-S21 (red): 0.5-1.5mm² SST-S11 (white): 0.25-0.34mm² Stripping Length: Approx. 10mm / 0.4in Working Temperature: -55-125 Start Shrinking Temperature: 80 The Temperature at Which the Solder Begins to Dissolve: 138 Complete Melting Temperature of Solder: 160 Shrinking Temperature: >160 Dielectric Strength: 1KW Protection Level: IP67 How to Use: 1. Get ready to strip the wires 2. The casing is inserted and the wires are connected 3. Heat it with a heat gun 4. Make it shrink and set Package List: 50 x Heat Shrink Tube

| Item NO. | Dimension | Lead Section | Color | ||||

| A(min) | L(min) | B(min) | B and C (min) | C(min) | A.W.G(mm²) | ||

| HXT-11 | 1.7 | 26 | 1.0 | 1.7 | 0.8 | 26-24(0.25-0.34) | ● white |

| HXT-21 | 2.7 | 40 | 1.4 | 2.7 | 1.2 | 22-18(0.5-1.0) | ● red |

| HXT-31 | 4.5 | 40 | 2.3 | 4.5 | 2.0 | 16-14(1.5-2.5) | ● blue |

| HXT-41 | 6.0 | 40 | 3.7 | 6.0 | 3.4 | 12-10(4.0-6.0) | ● yellow |

●Item 1 : Heat shrinkable Sleeve, Transparent, Radiation cross-linked modified polyolefin.

●Item 2: Solder Ring with flux.

●Item 3: Meltable rings