What Is Wire Crimping?

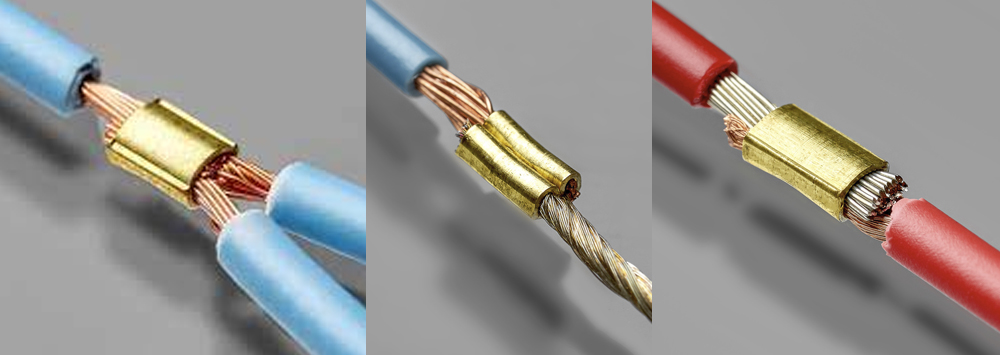

Wire crimping is a method of joining two or more electrical wires using a metal connector that’s compressed around the wire strands to create a permanent mechanical and electrical bond. The crimping process deforms the connector material, creating intimate contact between the connector and wire strands that ensures reliable current flow and mechanical strength.

Key Components of a Crimped Connection

- Crimp connector: Metal sleeve or terminal that houses the wire ends

- Wire strands: Stripped copper conductors that make electrical contact

- Compressed joint: The deformed connector that secures the connection

- Insulation: Protective covering that prevents short circuits

Types of Crimp Connectors and Applications

| Connector Type | Best Use Cases | Wire Gauge Range | Key Benefits |

|---|---|---|---|

| Butt Connectors | Straight-line connections | 22-10 AWG | Strongest mechanical bond |

| Ring Terminals | Screw terminal connections | 22-4 AWG | Secure mounting points |

| Spade Terminals | Quick-disconnect applications | 22-10 AWG | Easy removal/replacement |

| Wire Nuts (Twist-on) | Junction boxes | 18-6 AWG | Reusable connections |

| Heat Shrink Connectors | Outdoor/marine use | 22-10 AWG | Waterproof seal |

Essential Tools for Professional Wire Crimping

Primary Crimping Tools

Ratcheting Crimp Tool

Professional-grade tool with adjustable dies

- Price Range: $25-150

- Best For: Consistent, code-compliant crimps

- Wire Capacity: 22-10 AWG typically

Standard Wire Strippers

For removing insulation cleanly

- Automatic strippers: $15-40 (recommended)

- Manual strippers: $8-25 (basic option)

Multimeter

For testing connection integrity

- Digital multimeter: $20-75

- Essential for: Continuity and resistance testing

⚠️ Safety Warning

Never use pliers or non-crimping tools to compress electrical connectors. Improper crimping can create high-resistance connections that generate heat and pose fire hazards.

Step-by-Step Wire Crimping Process

Step 1: Prepare Your Workspace

- Turn off power at the circuit breaker

- Verify power is off using a non-contact voltage tester

- Gather all tools and materials in good lighting

- Wear safety glasses to protect from wire strands

Step 2: Select the Correct Connector

- Match connector size to wire gauge (check packaging)

- Choose insulated vs non-insulated based on application

- Verify connector rating matches circuit amperage

Step 3: Strip Wire Insulation

- Strip exactly 1/4 inch (6mm) of insulation from each wire end

- Use proper wire strippers to avoid nicking copper strands

- Clean stripping creates better electrical contact

Step 4: Insert Wires into Connector

- Slide both stripped wire ends fully into butt connector

- Ensure wire strands reach the center of the connector

- Copper should be visible through inspection window (if present)

Step 5: Position Crimping Tool

- Place connector in the correct crimp tool die

- Center the connector in the crimping area

- Align tool perpendicular to connector

Step 6: Execute the Crimp

- Apply steady, firm pressure to crimp tool handles

- For ratcheting tools: squeeze until tool releases automatically

- For standard tools: compress until connector deforms around wires

Step 7: Inspect the Connection

- Visually check for complete connector compression

- Gently tug each wire to verify mechanical strength

- Look for proper conductor contact through inspection windows

Wire Gauge and Connector Compatibility Chart

| Wire Gauge (AWG) | Connector Color | Typical Applications | Max Amperage |

|---|---|---|---|

| 22-18 | Red | Low-voltage electronics | 5-10 amps |

| 16-14 | Blue | Lighting circuits, outlets | 15-20 amps |

| 12-10 | Yellow | Appliances, HVAC | 20-30 amps |

| 8-6 | No standard color | Sub-panels, major appliances | 40-55 amps |

💡 Expert Tips for Professional Results

Tip 1: Match Wire Gauges

Always crimp wires of the same gauge together when possible. Mixing significantly different wire sizes can create poor connections.

Tip 2: Use Proper Connector Size

The connector should fit snugly around the wire bundle. Too large creates loose connections; too small damages wire strands.

Tip 3: Apply Dielectric Grease

For outdoor or high-vibration applications, apply a small amount of dielectric grease before crimping to prevent corrosion.

Tip 4: Test Every Connection

Use a multimeter to verify continuity and check resistance. Good crimped connections should show less than 0.1 ohms resistance.

Code Compliance and Safety Requirements

National Electrical Code (NEC) Standards

- Section 110.14: Requires proper connection methods for electrical safety

- UL Listed Connectors: Use only connectors certified for electrical applications

- Amperage Rating: Connector must meet or exceed circuit requirements

Local Building Codes

- Check local amendments to NEC requirements

- Some jurisdictions require licensed electrician for certain applications

- Permit requirements vary by project scope and location

Common Wire Crimping Problems and Solutions

| Problem | Cause | Solution |

|---|---|---|

| Weak mechanical bond | Under-crimped connector | Re-crimp with proper tool pressure |

| High electrical resistance | Poor wire insertion | Strip wires again, ensure full insertion |

| Connector splits | Over-crimping | Replace with new connector, reduce pressure |

| Corrosion at joint | Moisture infiltration | Use heat-shrink or marine-grade connectors |

When to Call a Professional Electrician

⚠️ Professional Required

- Main panel connections: Never attempt service panel work

- 240V circuits: High-voltage work requires licensing

- Aluminum wiring: Special connectors and techniques required

- Code compliance questions: Local electrical inspector consultation

DIY-Appropriate Projects

- Low-voltage electronics: 12V automotive, LED strips

- Appliance repairs: With proper shutoff procedures

- Extension cord repairs: Using appropriate gauge wire

- Outdoor lighting: Following manufacturer specifications

Alternative Connection Methods Comparison

| Method | Strength | Cost | Reusability | Best Applications |

|---|---|---|---|---|

| Crimped Connections | Excellent | Low-Medium | No | Permanent installations |

| Wire Nuts | Good | Low | Yes | Junction boxes, branch circuits |

| Lever Nuts | Good | Medium | Yes | Quick connections, troubleshooting |

| Soldered Joints | Excellent | Low | No | Electronics, precision work |

Quality Testing Your Crimped Connections

Visual Inspection Checklist

- ✅ Connector fully compressed around wire bundle

- ✅ No exposed copper visible outside connector

- ✅ Even compression along connector length

- ✅ No splits or cracks in connector material

Electrical Testing Process

- Continuity Test: Verify electrical path exists

- Resistance Test: Should read less than 0.1 ohms

- Pull Test: Apply 50% of wire’s tensile strength

- Insulation Test: Check for short circuits to ground

Expert Selection Criteria for Crimp Connectors

For Indoor Residential Use

- Choose UL-listed butt connectors with vinyl insulation

- Match color coding to wire gauge for easy identification

- Select ratcheting crimp tool for consistent results

For Automotive Applications

- Use tinned copper connectors for corrosion resistance

- Select heat-shrink connectors for moisture protection

- Choose tools designed for automotive wire gauges

For Marine/Outdoor Use

- Specify marine-grade connectors with adhesive heat shrink

- Use stainless steel or tinned copper materials

- Apply marine-grade electrical grease before crimping

Frequently Asked Questions

What makes crimped connections better than twisted wires?

Crimped connections provide superior mechanical strength and electrical conductivity compared to twisted connections. The metal-to-metal contact created by proper crimping eliminates the air gaps that can cause resistance and heat buildup in twisted joints.

Can you crimp different gauge wires together?

You can crimp wires that differ by one gauge size (e.g., 14 AWG with 12 AWG) using the appropriate connector size. However, connecting significantly different wire gauges can create poor connections and code violations.

How do you know if a crimp connection is good?

A properly crimped connection should pass both visual and electrical tests. Visually, the connector should be evenly compressed with no splits. Electrically, it should show continuity and resistance below 0.1 ohms while withstanding a pull test.

What tools do you need for professional wire crimping?

Essential tools include a ratcheting crimp tool, wire strippers, non-contact voltage tester, and multimeter. Professional work may also require specialized dies for specific connector types and wire gauges.

When should you use heat shrink vs regular crimp connectors?

Use heat shrink connectors in outdoor, marine, or high-vibration applications where moisture and environmental protection are critical. Regular vinyl-insulated connectors are sufficient for indoor, dry location applications.

Can crimped connections be undone and redone?

No, crimped connections are permanent. If you need to separate wires, you must cut the connector and start over with a new connector and properly stripped wire ends.

What wire stripping length is best for crimping?

Strip exactly 1/4 inch (6mm) of insulation for most crimp connectors. This provides optimal contact area while preventing exposed copper that could create short circuits.

Are there codes that require specific crimping methods?

Yes, the National Electrical Code (NEC) Section 110.14 requires proper connection methods. Local codes may have additional requirements, and some applications require UL-listed connectors and professional installation.

Professional Recommendations and Next Steps

For residential electrical work involving crimped connections, always:

- Use UL-listed connectors appropriate for your application

- Follow manufacturer specifications for wire gauge compatibility

- Test every connection before energizing circuits

- Consult local electrical codes for compliance requirements

When in doubt, consult a licensed electrician. Properly crimped wire connections are fundamental to electrical safety and system reliability. The investment in quality tools and proper technique pays dividends in long-term performance and code compliance.

Remember: electrical work can be dangerous. Always turn off power, verify it’s off, and follow all safety procedures. When working with circuits over 30 volts or in wet locations, professional installation may be required by local codes.