Direct Answer: Crimped electrical connections are often superior to soldered connections in many applications, offering better vibration resistance, faster installation, and easier maintenance. However, the “best” choice depends on your specific application, environmental conditions, and industry requirements.

Modern crimped connections, when properly executed with quality tools and connectors, can achieve connection integrity that meets or exceeds soldered joints in most electrical applications. Professional electricians and engineers increasingly favor crimped connections for their reliability and efficiency.

What Are Crimped and Soldered Electrical Connections?

Crimped Connections Defined

A crimped electrical connection joins two or more conductors by mechanically deforming a metal connector around the wire strands using specialized crimping tools. The connector material cold-flows around the wire strands, creating a gas-tight seal that maintains electrical continuity.

Soldered Connections Defined

A soldered electrical connection uses molten metal alloy (solder) to create a metallurgical bond between conductors. The solder flows into the spaces between wire strands and solidifies to form a permanent electrical and mechanical connection.

Key Differences: Crimped vs Soldered Connections

Here is a table that shows the fundamental differences between crimped and soldered electrical connections:

| Factor | Crimped Connections | Soldered Connections |

|---|---|---|

| Installation Speed | 5-10 seconds per connection | 30-60 seconds per connection |

| Vibration Resistance | Excellent – flexible connection point | Good – rigid but can crack |

| Temperature Range | -55°C to +125°C (varies by connector) | Limited by solder melting point (~180-220°C) |

| Rework Capability | Easy – cut and re-crimp | Difficult – requires desoldering |

| Initial Cost | Higher (quality crimping tools) | Lower (basic soldering equipment) |

| Long-term Reliability | Excellent in most environments | Very good in stable environments |

| Code Compliance | NEC approved for most applications | NEC approved with restrictions |

| Skill Level Required | Moderate (proper tool use) | High (temperature and timing control) |

Comparative Performance Analysis

Electrical Performance Comparison

Resistance Characteristics:

- Crimped: Typically 0.1-0.5 milliohms additional resistance

- Soldered: Nearly zero additional resistance when done properly

Current Carrying Capacity:

- Crimped: Maintains full wire ampacity with proper connector sizing

- Soldered: Can exceed wire ampacity but limited by heat generation during soldering

Mechanical Performance Comparison

Here is a table that shows mechanical performance differences:

| Performance Factor | Crimped | Soldered | Winner |

|---|---|---|---|

| Tensile Strength | 90-100% of wire strength | 95-100% of wire strength | Tie |

| Fatigue Resistance | Excellent (flexible joint) | Poor (rigid joint cracks) | Crimped |

| Vibration Tolerance | Superior | Adequate | Crimped |

| Thermal Cycling | Excellent expansion/contraction | Stress cracking possible | Crimped |

Applications and Use Cases

When Crimped Connections Excel

Automotive Applications:

- Engine bay connections (vibration and temperature extremes)

- Dashboard wiring (frequent movement and flexing)

- Trailer connections (weather exposure and repeated connect/disconnect)

Industrial Applications:

- Motor control panels (vibration from equipment)

- PLC installations (easy troubleshooting and modifications)

- Instrumentation wiring (precise, repeatable connections)

Marine and Outdoor Applications:

- Boat electrical systems (vibration and moisture resistance)

- Solar panel installations (thermal cycling and weather exposure)

- Outdoor lighting systems (easy maintenance access)

When Soldered Connections Are Preferred

Electronics Manufacturing:

- Circuit board assembly (precise, low-profile connections)

- High-frequency RF applications (minimal impedance discontinuity)

- Prototype development (easy modification and testing)

Audio/Video Equipment:

- Professional audio systems (lowest possible resistance)

- High-end speaker connections (audiophile applications)

- Broadcast equipment (signal integrity critical)

Specialty Applications:

- Medical devices (long-term reliability in stable environments)

- Aerospace (weight-critical applications with controlled environments)

- Scientific instruments (precision connections in controlled conditions)

Safety and Code Compliance Considerations

National Electrical Code (NEC) Requirements

Article 110.14 – Electrical Connections:

- Both crimped and soldered connections are approved methods

- Connections must be made with listed connectors and proper techniques

- Connection integrity must be maintained under all operating conditions

⚠️ Safety Warning: Always follow manufacturer specifications for connector selection and crimping tools. Improper crimping can result in loose connections, overheating, and fire hazards.

Professional Installation Standards

UL Listed Requirements:

- Crimping tools must be calibrated and designed for specific connector types

- Solder must meet appropriate ASTM standards (typically 60/40 or 63/37 tin/lead or lead-free alternatives)

- Connection methods must maintain wire ampacity ratings

Step-by-Step Installation Guides

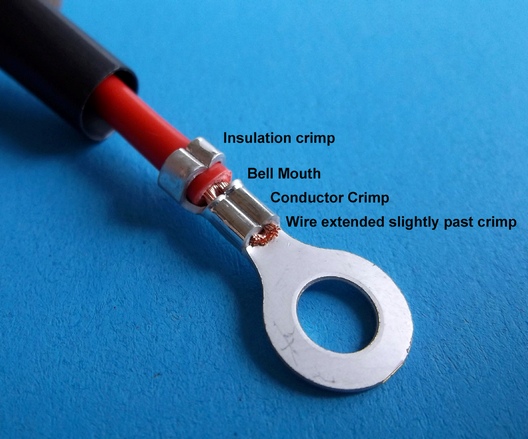

Proper Crimping Technique

- Strip wire to manufacturer’s specified length (typically 1/4″ to 3/8″)

- Insert wire fully into connector barrel until insulation touches connector shoulder

- Position crimping tool at center of connector barrel

- Apply steady pressure until tool releases (ratcheting tools ensure proper compression)

- Inspect crimp for proper compression and wire strand visibility through connector window

- Perform pull test according to manufacturer specifications

Proper Soldering Technique

- Strip wire to appropriate length for connection type

- Pre-tin conductors with thin layer of solder

- Heat joint area with appropriately sized soldering iron (15-25 watts for small wire)

- Apply solder to joint (not iron tip) until it flows completely around conductors

- Remove heat source and hold connection still until solder solidifies

- Inspect joint for complete coverage and proper fillet formation

Selection Criteria: How to Choose the Right Method

Environmental Factors Decision Matrix

| Condition | Choose Crimped | Choose Soldered |

|---|---|---|

| High Vibration | ✓ Recommended | ✗ Not recommended |

| Extreme Temperature Cycling | ✓ Recommended | ⚠️ Use with caution |

| Frequent Maintenance | ✓ Recommended | ✗ Difficult to service |

| Space Constraints | ⚠️ Bulkier connectors | ✓ Compact joints |

| High Current (>30A) | ✓ With proper sizing | ⚠️ Heat generation issues |

| Precision Electronics | ⚠️ Impedance effects | ✓ Excellent performance |

💡 Expert Tip: For installations requiring both vibration resistance and compact connections, consider insulation displacement connectors (IDC) as a third option that combines benefits of both methods.

Cost Analysis and ROI Considerations

Initial Investment Comparison

Crimping Setup Costs:

- Professional ratcheting crimper: $150-$500

- Connector inventory: $0.05-$2.00 per connection

- Wire strippers: $25-$75

Soldering Setup Costs:

- Quality soldering station: $75-$300

- Solder and flux: $20-$50

- Heat shrink tubing: $0.02-$0.10 per connection

Long-term Economic Factors

Labor Time Comparison:

- Crimped connections: 10-15 connections per minute (experienced technician)

- Soldered connections: 3-5 connections per minute (experienced technician)

Maintenance and Troubleshooting:

- Crimped: Easy disconnect and reconnect for testing

- Soldered: Requires desoldering and resoldering for changes

Common Problems and Troubleshooting

Crimped Connection Issues

Problem: Loose or intermittent connections

Causes: Improper tool calibration, wrong connector size, insufficient compression

Solutions: Use properly calibrated tools, verify connector specifications, perform pull tests

Problem: Corrosion at connection point

Causes: Moisture infiltration, dissimilar metals, inadequate sealing

Solutions: Use sealed connectors, apply dielectric grease, ensure proper environmental rating

Soldered Connection Issues

Problem: Cold solder joints

Causes: Insufficient heat, contaminated surfaces, movement during cooling

Solutions: Proper iron temperature, clean surfaces, maintain stability during cooling

Problem: Cracked joints from thermal cycling

Causes: Rigid connection subjected to expansion/contraction

Solutions: Stress relief loops, flexible conductor routing, appropriate solder alloy selection

Professional Recommendations

Industry Best Practices

For Commercial Installations:

- Use crimped connections for power distribution and motor circuits

- Reserve soldering for control circuits and electronics integration

- Follow manufacturer torque specifications for all threaded connections

For Residential Work:

- Crimped connections preferred for most applications per NEC guidelines

- Wire nuts remain standard for branch circuit splicing

- Soldering limited to specialty applications and repairs

💡 Expert Tip: Many professional electricians use a hybrid approach: crimped connections for power circuits and mechanical reliability, soldered connections for precision electronics and signal integrity.

Quality Assurance and Testing

Connection Verification Methods

Visual Inspection Criteria:

- Crimped: Uniform compression, no exposed strands, proper connector fill

- Soldered: Smooth fillet, complete conductor coverage, no cold joint appearance

Electrical Testing:

- Resistance measurement should not exceed 10% above calculated conductor resistance

- Insulation resistance testing per manufacturer specifications

- Pull testing to verify mechanical integrity

🔧 Professional Requirement: All electrical connections in commercial installations should be tested for proper resistance and mechanical integrity before energizing circuits.

Frequently Asked Questions

Can I use crimped connections in wet locations?

Yes, but only with connectors rated for wet locations (typically IP67 or higher). Apply dielectric grease and ensure proper sealing to prevent corrosion.

Why do some electricians prefer soldered connections for audio systems?

Soldered connections provide the lowest possible resistance and eliminate potential noise from microscopic movement in crimped connections, which can be audible in high-end audio systems.

Are crimped connections acceptable for high-voltage applications?

Yes, when using properly rated connectors and following manufacturer specifications. Many utility companies prefer crimped connections for overhead and underground power distribution.

How long should crimped connections last?

Properly installed crimped connections can last 20-30 years or more in appropriate environments. Lifespan depends on environmental conditions, current loading, and connector quality.

Can I mix crimped and soldered connections in the same circuit?

Yes, there’s no electrical reason preventing this. Choose the appropriate method based on each connection’s specific requirements and environmental conditions.

What’s the minimum wire gauge for reliable crimping?

Most quality crimping tools and connectors work reliably down to 22 AWG. For smaller gauges, soldering is typically more practical and reliable.

Do crimped connections require special maintenance?

Minimal maintenance beyond normal visual inspection. Check for signs of overheating, corrosion, or mechanical damage during routine electrical system inspections.

Are there any NEC restrictions on crimped vs soldered connections?

The NEC allows both methods when properly executed with listed materials. Some specific applications may have preferences, but both are generally acceptable for most installations.

Quick Reference Decision Guide

Choose Crimped Connections When:

- ✓ Installation speed is important

- ✓ Vibration resistance is required

- ✓ Easy maintenance access is needed

- ✓ Working in harsh environmental conditions

- ✓ Making numerous repetitive connections

Choose Soldered Connections When:

- ✓ Minimum electrical resistance is critical

- ✓ Space constraints require compact joints

- ✓ Working on precision electronic circuits

- ✓ Permanent installation in controlled environment

- ✓ Audio/signal integrity is paramount

Conclusion: Making the Right Connection Choice

The question “Are crimps as good as solders?” doesn’t have a simple yes or no answer. Both methods excel in different applications, and understanding their strengths helps you make informed decisions for specific projects.

Key Takeaways:

- Crimped connections offer superior vibration resistance and faster installation

- Soldered connections provide minimal electrical resistance and compact profiles

- Environmental conditions and application requirements should drive your choice

- Both methods are NEC-compliant when properly executed with quality materials

- Professional installation techniques are critical for either method’s success

For most electrical work, crimped connections provide the optimal balance of reliability, speed, and maintainability. However, specialized applications may benefit from soldered connections’ unique advantages.

When in doubt, consult with a licensed electrician who can evaluate your specific application requirements and local code compliance needs. Proper technique and quality materials matter more than the connection method itself in achieving long-term electrical system reliability.