Every season, irrigation contractors face the same problem: callbacks for failed sprinkler zones caused by corroded wire connections. A single moisture-compromised splice can shut down an entire valve bank, costing you time, materials, and customer trust. The culprit? Standard wire nuts used in wet environments where they have no business being.

Waterproof wire nuts solve this chronic problem by sealing electrical connections against moisture infiltration in irrigation valve boxes, direct-burial splices, and other wet locations. When installed correctly, these silicone-filled or grease-sealed connectors protect wire junctions from water, corrosion, and environmental degradation—extending system life and eliminating the majority of connection-related failures.

This guide walks you through professional installation techniques for waterproof wire nuts in sprinkler systems, covering material selection, step-by-step procedures, NEC compliance, common mistakes, and B2B sourcing considerations for contractors managing multiple projects.

Figure 1: Professional irrigation valve box showing multiple wire connection points where waterproof wire nuts protect against moisture damage. Organized color-coded wiring connects controller signals to individual solenoid valves.

What Are Waterproof Wire Nuts and Why They Matter

The Technology Behind Waterproof Wire Nuts

Unlike standard twist-on wire nuts that rely solely on a threaded plastic shell and spring contact, waterproof wire nuts incorporate moisture-sealing technology. Most designs combine a traditional connector with a silicone-filled or grease-filled housing that encapsulates the splice point. When you insert stripped wires and twist the connector into place, the silicone or grease compound fills all voids around the conductors, creating a moisture barrier that prevents water ingress and oxygen exposure—the two primary causes of connection corrosion.

Quality waterproof wire nut connectors are rated to IP67 or IP68 standards, meaning they can withstand temporary immersion (IP67) or sustained contact with water (IP68, though many are not rated for continuous submersion). The housing is typically UV-resistant polypropylene or similar thermoplastic, critical for valve box applications where sunlight exposure occurs during maintenance.

When Standard Wire Nuts Fail in Irrigation Systems

Sprinkler system valve boxes present a uniquely harsh environment. Irrigation cycles introduce humidity and condensation; rain events can partially flood boxes; and soil moisture constantly surrounds buried connections. Standard wire nuts—designed for dry or damp interior locations—allow moisture to wick along wire strands under the connector. Over time, copper oxidizes, resistance increases, and solenoid valves fail to energize reliably. I’ve seen systems less than two years old require complete re-splicing because installers used hardware-store wire nuts instead of waterproof wire connectors rated for wet locations.

Code Compliance: NEC Requirements for Wet Locations

The National Electrical Code (NEC) Article 314.15 requires that boxes and fittings in wet locations be listed for wet-location use and installed to prevent moisture accumulation. While most residential irrigation systems operate at low voltage (24 VAC), professional installations still follow these best practices to ensure long-term reliability and avoid liability.

Waterproof wire nuts designed for direct burial and wet locations are typically UL-listed to standards such as UL 486D or UL 486G. UL 486G specifically addresses sealed twist-on connectors and permits their use in wet, damp, and direct-buried applications—including irrigation cable and low-voltage lighting circuits. For contractors working on commercial properties or municipal projects, using UL-listed waterproof wire connectors isn’t optional; it’s part of the specification.

Where to Use Waterproof Wire Nuts in Sprinkler Systems

Waterproof wire nuts are essential at these connection points:

- Valve box splices: Where home-run wiring from the controller splits to individual solenoid leads

- Direct-burial junctions: Mid-run splices in underground cable

- Outdoor controller terminals: When wiring exits the building and transitions to buried cable (if not in conduit)

- Pump relay and master valve wiring: Higher-current connections exposed to moisture

- Repair splices: Any field repair in wet or buried irrigation wiring

Essential Materials and Tools

Selecting the Right Waterproof Wire Nuts

Choose connectors based on wire gauge and conductor count. Most irrigation wiring uses 18 AWG or 14 AWG multi-conductor cable for solenoid valve circuits. Check the product datasheet for approved wire combinations—a typical waterproof wire nut rated for irrigation use will accommodate combinations such as:

- Two to five 18 AWG conductors

- Two to four 14 AWG conductors

- Mixed gauges (e.g., one 14 AWG common wire plus three 18 AWG zone wires)

Look for these specifications:

- UL listing: UL 486D or UL 486G for wet/direct-burial use

- Voltage rating: 600V (standard for most products, far exceeding the 24 VAC irrigation requirement)

- IP rating: IP67 minimum; IP68 preferred for frequently wet valve boxes

- Temperature range: Operating range of -40°C to 105°C covers most climates

- UV resistance: Critical if any portion of the connection is exposed to sunlight

Wire and Cable Considerations

Use copper conductors only—waterproof wire nuts are not rated for aluminum. Irrigation cable is typically multi-conductor, direct-burial rated (DB), with PVC or polyethylene jacket. Common types include:

- 18 AWG multi-conductor: Standard for residential valve wiring up to 1,000 feet

- 14 AWG multi-conductor: For longer runs or higher solenoid counts to reduce voltage drop

- Stranded vs. solid: Both work; stranded is more flexible for tight valve boxes

Required Tools

- Wire strippers: Adjustable or sized for 18-14 AWG; self-adjusting models reduce the risk of nicking strands

- Diagonal cutters: For clean wire cuts

- Multimeter: To verify continuity and test for shorts before and after splicing

- Flashlight/headlamp: Valve box work often happens in dim conditions

Optional but Recommended

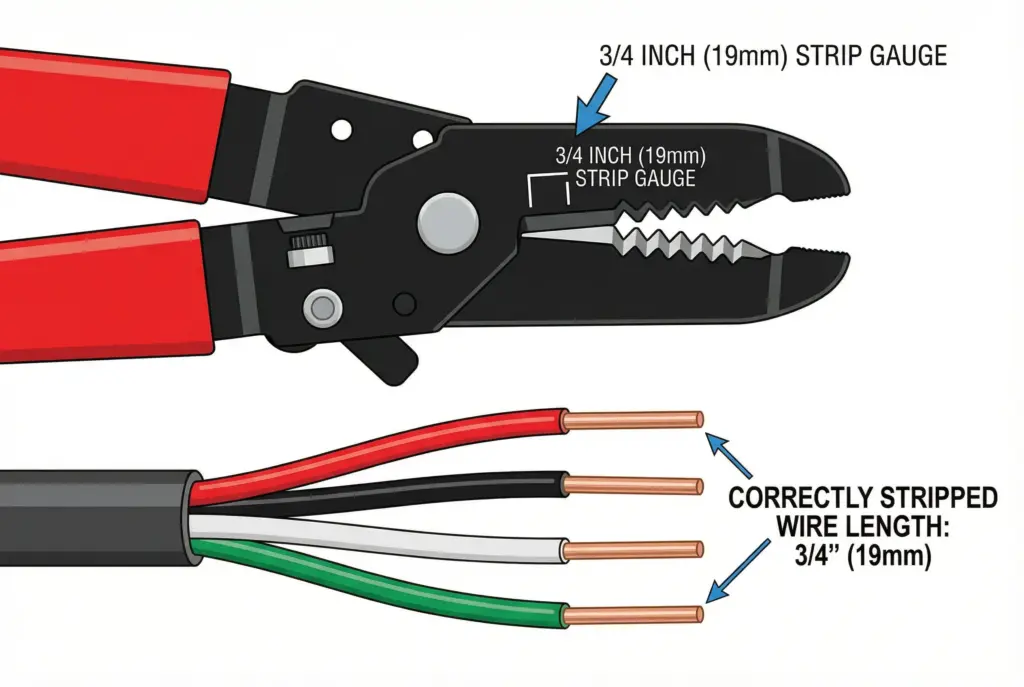

Figure 2: Proper wire preparation requires precise 3/4 inch (19mm) strip length. Using calibrated wire strippers ensures clean copper exposure without damaging conductor strands—critical for secure waterproof connections.

- Silicone grease or dielectric compound: Extra moisture protection on connections (though most waterproof wire nuts include internal sealant)

- Cable labels: For identifying zones during troubleshooting

- Gravel or drainage mat: Improve valve box drainage and reduce standing water around splices

Step-by-Step Installation Guide for Waterproof Wire Nuts

Step 1: Prepare the Workspace and Inspect Wires

Before opening any waterproof wire nut package, ensure your work area is as dry as possible. If working in a valve box after rain, bail out standing water and let the box air for a few minutes. Inspect all wire insulation for nicks, cuts, or deterioration—damaged insulation should be cut back to sound cable.

Verify wire colors and function with a multimeter if you’re troubleshooting an existing system. Common wires are often white or black; zone wires are typically color-coded (red, blue, green, yellow, etc.). Label wires if necessary before disconnecting anything.

Step 2: Strip Wire Insulation to the Correct Length

This is the most critical measurement in the entire installation. Most waterproof wire nuts specify a strip length of 3/4 inch (19 mm). Too little exposed copper and the connector won’t grip properly; too much and bare wire extends beyond the seal, inviting corrosion.

Using wire strippers:

- Set the tool to the correct gauge (18 or 14 AWG)

- Position the stripper 3/4 inch from the wire end

- Squeeze and rotate gently to score the insulation

- Pull the insulation straight off—avoid twisting, which can fray stranded wire

Inspect the stripped end. Copper strands should be bright and intact, with no nicks or cuts. If you see damaged strands, trim the wire and re-strip.

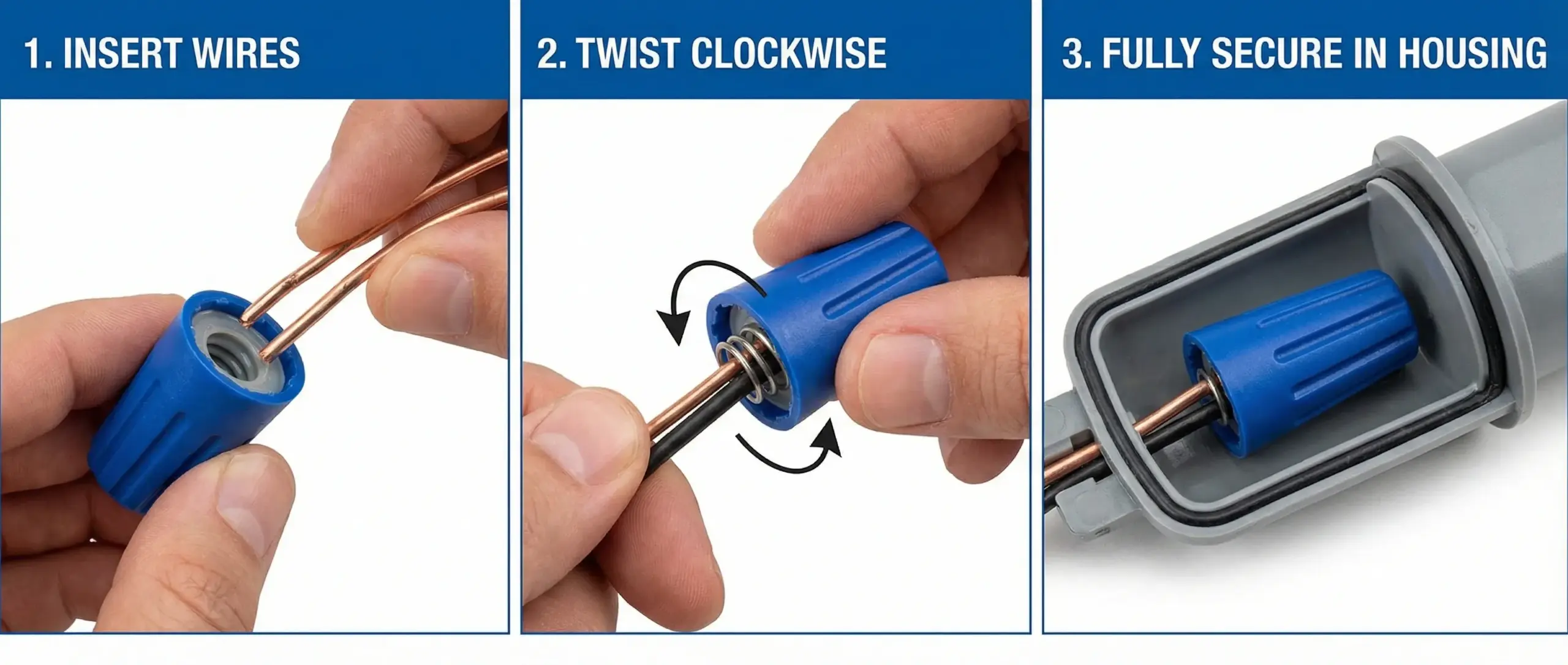

Step 3: Align and Insert Wires into the Connector

Gather all wires that will share the connection (e.g., common wire plus all zone commons). Hold them with insulation ends even—staggered ends create connection problems and prevent proper sealing.

For silicone-filled waterproof wire nuts with a separate housing tube:

- Slide the housing tube onto one of the wires before inserting into the connector (easy to forget this step)

- Insert all wire ends into the twist-on connector

- Push wires fully into the connector base until insulation just touches the opening

For all-in-one sealed connectors:

- Insert wires directly into the connector opening

- Ensure all conductors enter together and seat against the internal spring

Step 4: Twist and Tighten the Connection

Hold the wire bundle firmly in one hand and rotate the connector clockwise (right-hand thread) with steady, continuous pressure. You’ll feel initial resistance as the internal spring engages the copper strands, followed by tightening as the threads draw down.

Twist until secure—typically 3-5 full turns for small wire counts, more for larger bundles. The connector should feel snug and the wire bundle should not pull free with moderate force. Do not over-torque; cracked housings defeat the waterproof seal.

Step 5: Seat the Connector in the Waterproof Housing

For two-piece designs with a grease-filled tube:

- Push the completed twist-on connector down to the bottom of the tube (you should feel it seat against the tube base)

- Fold or arrange wires into the tube’s wire channels

- Snap or screw the cap closed

Verify there are no air gaps or voids visible in the grease or silicone compound—trapped air pockets create water paths. The sealant should completely encapsulate the connection zone.

Step 6: Test the Connection

Before burying or closing up the valve box:

- Continuity test: Use a multimeter to confirm low resistance across the splice (<1 ohm)

- Function test: Energize the circuit (turn on the zone from the controller) and verify the solenoid activates

- Physical test: Gently tug each wire—none should pull free from the connector

Step 7: Position and Protect the Splice

Place the completed waterproof wire nut in the valve box so it’s elevated above the box floor if possible. Use wire hangers, zip ties to a manifold, or rest connections on valve bodies—anything to keep them out of standing water, even though they’re rated for wet conditions.

If you’re making a direct-burial splice (no box), ensure the splice is at least 6 inches below finished grade per NEC Table 300.5 for irrigation circuits. Backfill carefully to avoid crushing the connection.

Coil excess wire neatly and secure with a cable tie. Replace the valve box cover. The installation is complete.

Figure 3: Step-by-step installation sequence shows proper technique: (1) insert stripped wires into silicone-filled connector, (2) twist clockwise until secure, (3) seat completed connection in protective housing to ensure complete moisture seal.

Best Practices for Long-Term Reliability

Managing Valve Box Drainage

Even with IP68-rated waterproof wire nuts, continuous submersion isn’t ideal. Most products carry a caveat: “not recommended for long-term continuous submersion.” That means chronically flooded valve boxes can still cause problems over years of service.

Improve drainage by:

- Installing valve boxes on a 2-3 inch gravel base

- Drilling small drainage holes (3-6 mm / 1/8–1/4 inch) at the lowest point of wet-location-rated boxes (per NEMA guidance and NEC allowance)

- Sloping the box floor slightly toward the drain hole

- Elevating connections on the valve manifold or using wire supports

These steps reduce water contact time and extend connection life.

Environmental and UV Considerations

If any portion of the waterproof wire nut housing is exposed to sunlight (e.g., in an open valve box or surface-mounted junction), UV degradation becomes a factor. Specify UV-resistant housings—look for polypropylene or similar materials with UV stabilizers. Some manufacturers explicitly rate products for outdoor UV exposure; others recommend enclosing connections in a covered box.

Temperature cycling also matters. In regions with freeze-thaw cycles, moisture trapped in improperly sealed connections expands when frozen, cracking housings or forcing apart conductors. A correctly installed waterproof wire nut prevents moisture entry in the first place, eliminating this risk.

Periodic Inspection and Maintenance

Set a maintenance schedule:

- Year 1-2: Open valve boxes during routine system checks and visually inspect connections for discoloration, corrosion, or housing cracks

- Every 3-5 years: Test electrical continuity and resistance on all splices; any connection showing elevated resistance (>2 ohms) warrants re-splicing

- After major flooding or soil disturbance: Re-inspect buried and boxed connections to confirm seals remain intact

Documenting connection dates (via cable labels or site plans) helps track service life and identify patterns if certain locations fail prematurely—often a sign of poor drainage or undersized wire.

Secondary Sealing Methods

For extremely harsh environments (coastal saltwater exposure, industrial chemical sites, or systems with known chronic flooding), contractors sometimes add secondary protection:

- Self-fusing silicone tape: Wrap over the completed waterproof wire nut for an additional moisture barrier

- Heat-shrink tubing with adhesive lining: Slide over the connection before assembly, then shrink after completing the splice

- Potting compound: For permanent, non-serviceable connections

These methods exceed typical residential irrigation needs but can justify themselves on high-value commercial or municipal projects where system downtime is costly.

Figure 4: Professional installation demonstrates best practices—waterproof wire nut connections elevated above box floor, organized wiring prevents tangling, gravel base improves drainage, and proper spacing allows maintenance access.

Common Mistakes to Avoid

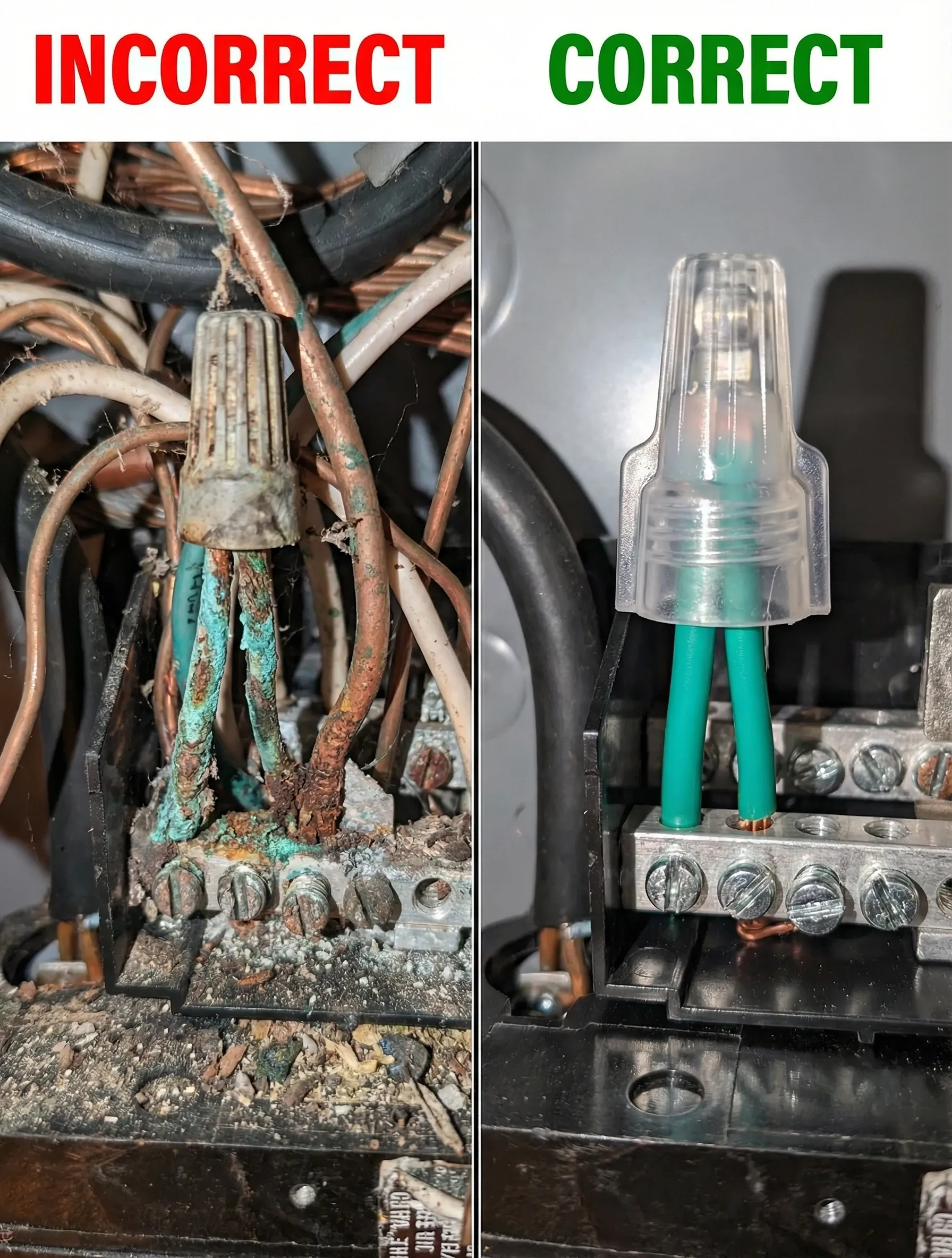

Mistake 1: Using Standard Wire Nuts in Wet Locations

This is the number-one error. Standard twist-on wire nuts—even high-quality brands—are not rated for continuous moisture exposure. They rely on the threaded shell and spring to exclude some moisture, but capillary action draws water along wire strands under the connector. Within months, green corrosion (copper oxide) builds up, resistance increases, and connections fail. If your project involves any outdoor, underground, or valve-box wiring, specify waterproof wire nuts from the start.

Mistake 2: Incorrect Strip Length

Stripping too little wire (e.g., 1/2 inch when 3/4 inch is specified) reduces the contact area between the spring and conductors, leading to high resistance and overheating under load. Stripping too much leaves bare copper exposed beyond the sealant, where it corrodes. Always follow the manufacturer’s strip-length specification—usually 3/4 inch for irrigation-class connectors—and verify with a ruler or strip gauge until you develop consistent technique.

Mistake 3: Overstuffing the Connector

Each waterproof wire nut has a maximum wire count and gauge combination listed in its datasheet. Jamming in too many or too-large conductors prevents the spring from engaging properly and forces sealant out of the housing, creating voids. For example, trying to connect six 14 AWG wires in a connector rated for four will almost certainly fail. Check the wire combination chart and, if necessary, use a larger connector or split the splice into multiple connections.

Mistake 4: Forgetting the Housing Tube

On two-piece waterproof wire nut designs (twist-on connector + separate grease-filled tube), it’s easy to complete the twist-on connection and realize the housing tube is still sitting on the ground. The fix requires disassembling everything and starting over. Make it a habit: slide the tube onto one wire before inserting wires into the connector.

Mistake 5: Leaving Air Voids in Sealant

After seating the connector in the tube and closing the cap, inspect the sealant. If you see air bubbles or gaps, water can enter. Work the connector down fully, ensuring grease or silicone fills all spaces around wires and the connector body. Some installers gently squeeze the tube while seating the connector to force sealant into voids.

Mistake 6: Ignoring Drainage and Box Placement

Installing a valve box in a low spot guarantees it will flood during rain. Even waterproof wire nuts suffer when connections spend weeks underwater. Site valve boxes on high ground or improve drainage with gravel and weep holes. Elevate connections inside the box so they’re not sitting in water. These steps extend service life dramatically.

Figure 5: Common mistake comparison—LEFT shows severe corrosion from using standard wire nuts in wet locations (green oxidation, moisture damage, connection failure). RIGHT shows properly sealed waterproof wire nut protecting conductors from moisture infiltration.

B2B Sourcing: Choosing the Right Supplier for Waterproof Wire Nuts

For electrical contractors, irrigation professionals, and facility managers purchasing waterproof wire nuts in volume, supplier selection impacts both project cost and long-term reliability. Here’s what to evaluate when sourcing for commercial or multi-site installations.

Verify Certifications and Compliance Documentation

Request product datasheets that clearly state:

- UL listing number (UL 486D or UL 486G) and scope of listing (wet locations, direct burial, irrigation cable)

- IP rating with test reports or certificates

- Temperature and voltage ratings

- Wire gauge and conductor count combinations

Reputable B2B suppliers provide this documentation upfront. If a supplier can’t produce a UL file number or IP rating certificate, the product may not meet code requirements—an unacceptable risk on inspected projects.

Evaluate Bulk Pricing and Minimum Order Quantities

Waterproof wire nut pricing drops significantly at volume. Compare:

- Unit pricing at different quantities (100, 500, 1,000+ units)

- Mixed-size orders: Can you combine different connector sizes in one order to reach volume discounts?

- Shipping costs and lead times: Domestic warehousing often beats overseas direct shipment on small to mid-size orders

For large projects (municipal systems, commercial developments, multi-property contracts), negotiate annual supply agreements with guaranteed pricing and stocking.

Assess Product Consistency and Quality Control

Batch-to-batch consistency matters. A supplier with strong QC delivers connectors where every unit has the correct sealant fill, housing integrity, and internal spring tension. Ask about:

- Manufacturing location and quality certifications (ISO 9001, etc.)

- Defect rates and warranty policies

- Sample availability: Request samples from current production before committing to large orders

Why Tonful Electric for Waterproof Wire Nuts

As a B2B low-voltage electrical components manufacturer, Tonful Electric specializes in waterproof connection solutions for demanding outdoor and industrial applications. Our waterproof wire nut product line includes:

- UL-listed connectors for wet locations and direct burial, compliant with NEC requirements

- IP68-rated designs with silicone and grease-filled options

- Wire gauge ranges covering 18-10 AWG for irrigation, landscape lighting, and low-voltage control circuits

- Flexible MOQs and volume pricing for contractors and distributors

- Technical support: Our applications engineers assist with product selection, spec compliance, and field troubleshooting

Whether you’re specifying components for a single commercial irrigation project or establishing a supply chain for ongoing operations, Tonful Electric delivers factory-direct quality with the documentation and support professional contractors require.

Contact us for product datasheets, sample requests, and bulk pricing tailored to your project needs.

Conclusion

Waterproof wire nuts are a small component with outsized impact on irrigation system reliability. When you seal every connection properly—correct strip length, appropriate connector size, full sealant encapsulation, and smart valve box placement—you eliminate the majority of service callbacks related to corroded splices and failed solenoid circuits.

The installation process is straightforward, but the details matter. Follow manufacturer specifications for strip length and wire combinations. Test every connection before closing up the box. Plan for drainage so connections aren’t sitting in standing water for weeks at a time. And when sourcing materials for commercial projects, partner with suppliers who provide the certifications, consistency, and technical support that professional installations demand.

For contractors managing multiple irrigation projects or facility managers overseeing large properties, reliable waterproof wire connectors aren’t just a code requirement—they’re an investment in system uptime and your professional reputation.

Ready to specify waterproof wire nuts for your next project? Contact Tonful Electric for technical datasheets, product samples, and volume pricing on UL-listed waterproof connectors designed for irrigation and outdoor low-voltage applications.