In today’s fast-paced industrial landscape, efficiency, reliability, and serviceability are paramount. From complex automotive wiring harnesses to the control panels of sophisticated manufacturing equipment, the ability to make secure and fast electrical connections is a non-negotiable requirement. This is where Quick Disconnect Terminals become essential components for engineers, technicians, and system integrators. These versatile connectors, also known as spade or tab terminals, provide a robust, solderless method for connecting and disconnecting wires, significantly reducing assembly time and simplifying field maintenance.

As a leading B2B manufacturer, TONFUL Electric understands that the quality of a connection is critical to the performance and longevity of any electrical system. This comprehensive guide explores the types, sizes, and industrial applications of quick disconnect terminals, providing the technical insights needed to select the perfect terminal for your project.

What Are Quick Disconnect Terminals?

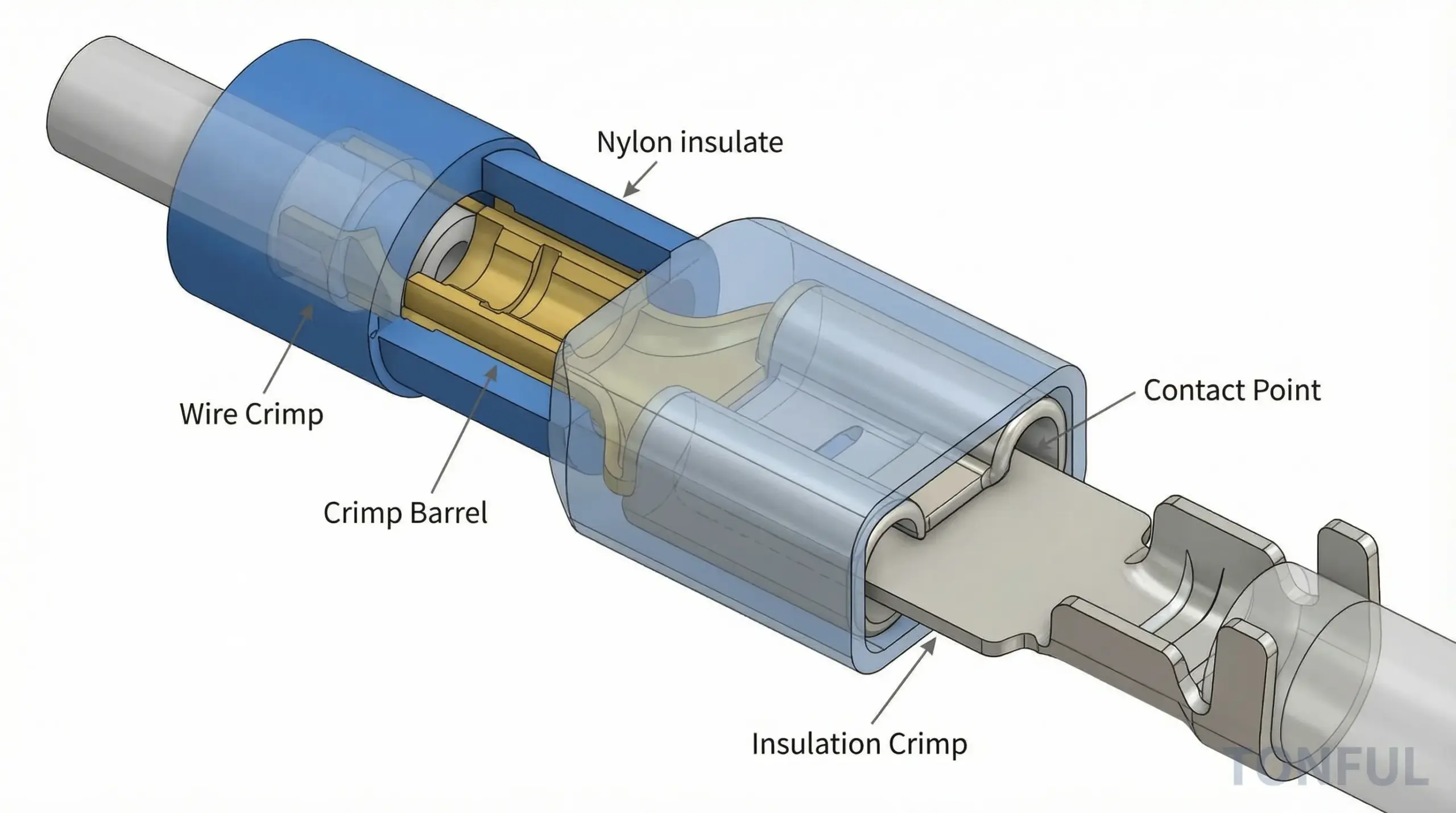

At their core, quick disconnect terminals are a two-part connection system consisting of a male “tab” (or blade) and a female “receptacle.” The female terminal is designed to slide snugly over the male tab, creating a secure mechanical and electrical connection that can be easily pulled apart when needed. This simple yet effective design eliminates the need for soldering or using screw terminals in many applications, offering a significant advantage in environments requiring frequent component changes or rapid assembly.

The primary benefits include:

- Speed: Dramatically accelerates assembly and repair times.

- Reliability: Provides a consistent, vibration-resistant connection when properly crimped.

- Serviceability: Allows for easy component replacement without cutting and re-stripping wires.

- Versatility: Available in a vast range of sizes, materials, and insulation types to suit countless applications.

Technical diagram showing the cutaway view of a TONFUL male and female quick disconnect terminal, illustrating the secure crimp and contact points.

Types of Quick Disconnect Terminals

Quick disconnects come in several form factors, each designed for specific spatial and functional requirements. Understanding these variations is the first step in selecting the right component.

A variety of TONFUL’s high-performance quick disconnect terminals for diverse applications.

Female Receptacles & Male Tabs

This is the most common pairing. The female receptacle features a rolled housing that accepts the male tab. The male tab is the simple blade-style terminal that is inserted into the receptacle. They are used to terminate a wire and connect it to a component or another wire.

Flag Terminals

Also known as right-angle terminals, flag terminals have a 90-degree orientation. The wire is crimped perpendicular to the direction of the connection. This design is invaluable in tight spaces where a straight connection is not feasible, such as behind panels or against bulkheads.

Piggyback Terminals

A piggyback terminal is a clever design that combines a female receptacle with a male tab on its back. This allows another female terminal to be connected, or “piggybacked,” onto the same point. It is extremely useful for daisy-chaining power or creating a tap point in a circuit without needing a separate splice.

Comparison of Quick Disconnect Terminal Styles

| Terminal Type | Description | Primary Use Case |

|---|---|---|

| Female Receptacle | The standard socket-style terminal that receives the male tab. | Connecting a wire to a male tab on a component (switch, relay, speaker). |

| Male Tab | The blade-style terminal that plugs into the female receptacle. | Creating a connection point for a wire or joining two female-terminated wires. |

| Flag Terminal | A female receptacle with a 90-degree orientation for the wire crimp. | Space-constrained applications where wires must run parallel to the panel surface. |

| Piggyback Terminal | A female receptacle with an integrated male tab on its back. | Daisy-chaining connections, creating tap points, or splitting a circuit. |

Insulated vs. Non-Insulated Terminals

The choice between insulated and non-insulated terminals is dictated by the application’s environment and safety requirements.

- Non-Insulated Terminals: These are bare metal terminals. They are cost-effective and allow for easy visual inspection of the crimp. However, they offer no protection against short circuits if they contact other conductors and are more susceptible to environmental corrosion. They are best suited for use inside enclosed, controlled environments.

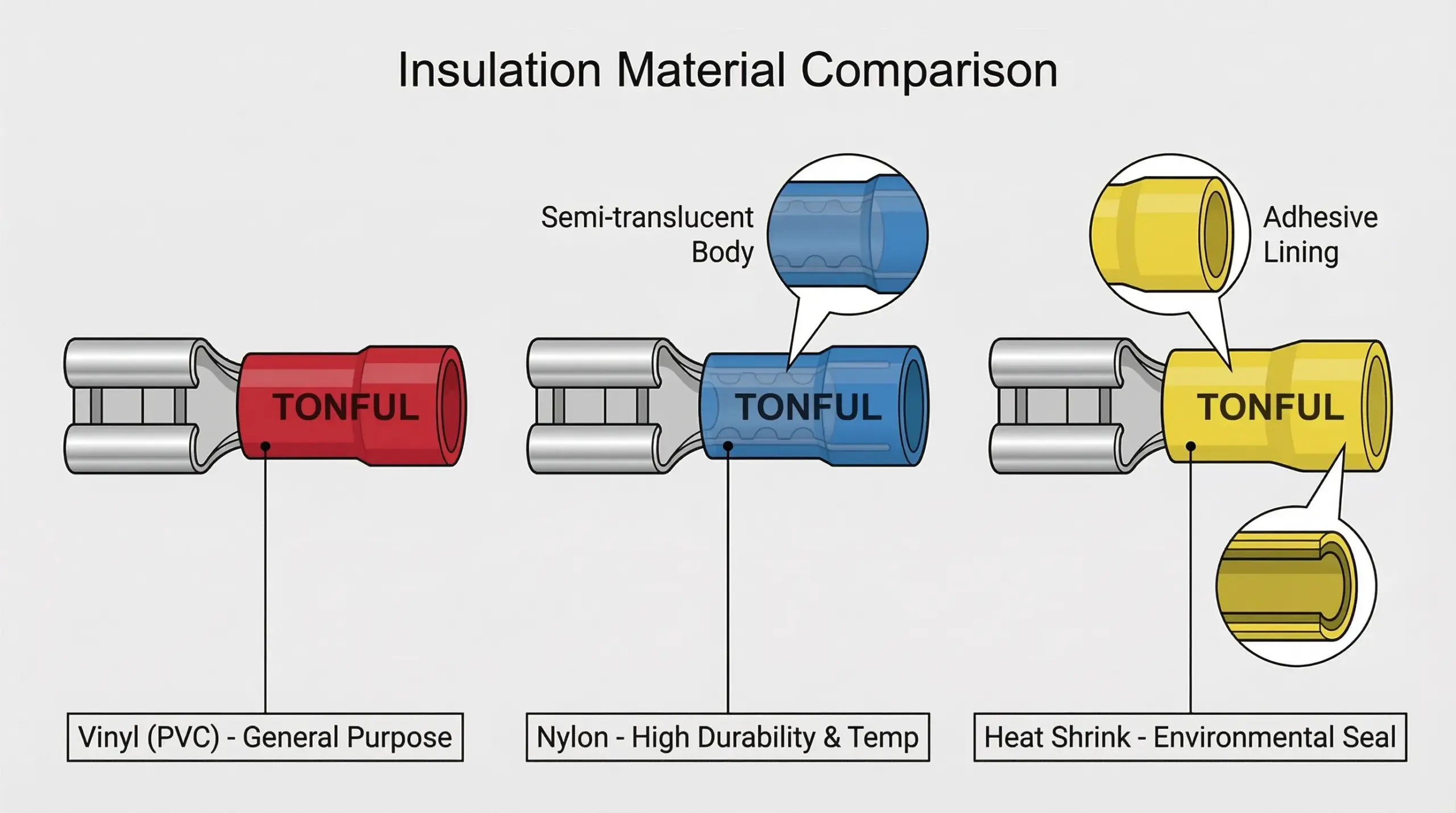

- Insulated Terminals: These terminals feature a protective sleeve, typically made of vinyl (PVC), nylon, or heat-shrink polyolefin, that covers the crimp barrel. The insulation prevents accidental shorting, provides strain relief for the wire, and protects the connection from moisture and contaminants.

Insulation Material Comparison

| Insulation Type | Temperature Rating | Durability & Abrasion Resistance | Environmental Seal | Cost | Best For |

|---|---|---|---|---|---|

| Vinyl (PVC) | Good (up to 75-90°C) | Moderate | None | Low | General purpose, stable, dry environments. |

| Nylon | Better (up to 105°C) | High | None | Medium | Automotive, industrial control panels, high-vibration areas. |

| Heat Shrink | Excellent (up to 125°C) | Excellent | Excellent (Waterproof) | High | Marine, off-road vehicles, harsh industrial or outdoor environments. |

Comparison diagram of TONFUL Vinyl, Nylon, and Heat Shrink insulated quick disconnect terminals, highlighting their features.

Standard Sizes and Wire Gauge Compatibility

Selecting the correct terminal size is crucial for a safe and reliable connection. There are two key measurements: the tab size and the wire gauge.

Common Tab Sizes

Quick disconnect terminals are commonly categorized by the width of the male tab. These sizes are standardized to ensure interoperability between manufacturers.

| Standard Imperial Size | Metric Equivalent (Approx.) | Common Applications |

|---|---|---|

| 0.110″ | 2.8 mm | Small switches, sensors, control signals, automotive electronics. |

| 0.187″ | 4.8 mm | Appliance switches, automotive relays, smaller speakers, general use. |

| 0.250″ | 6.35 mm | The most common size. Used in appliances, automotive, industrial controls, power connections. |

| 0.312″ | 7.9 mm | Higher-current applications, industrial machinery. |

Wire Gauge and Color Coding

Insulated terminals use a standard color code to identify the range of wire sizes (measured in American Wire Gauge or AWG) they are designed to accept. Using the correct size ensures a proper crimp that is both mechanically strong and electrically sound.

| Insulation Color | Wire Gauge (AWG) | Typical Current Capacity |

|---|---|---|

| Red | 22-18 AWG | Up to ~7 Amps |

| Blue | 16-14 AWG | Up to ~15 Amps |

| Yellow | 12-10 AWG | Up to ~25 Amps |

| (No Color/Black/Gray) | 8 AWG and larger | Varies (Higher Current) |

Note: Always consult the wire and terminal manufacturer’s specifications. Current ratings are approximate and depend on the specific application, temperature, and wire type.

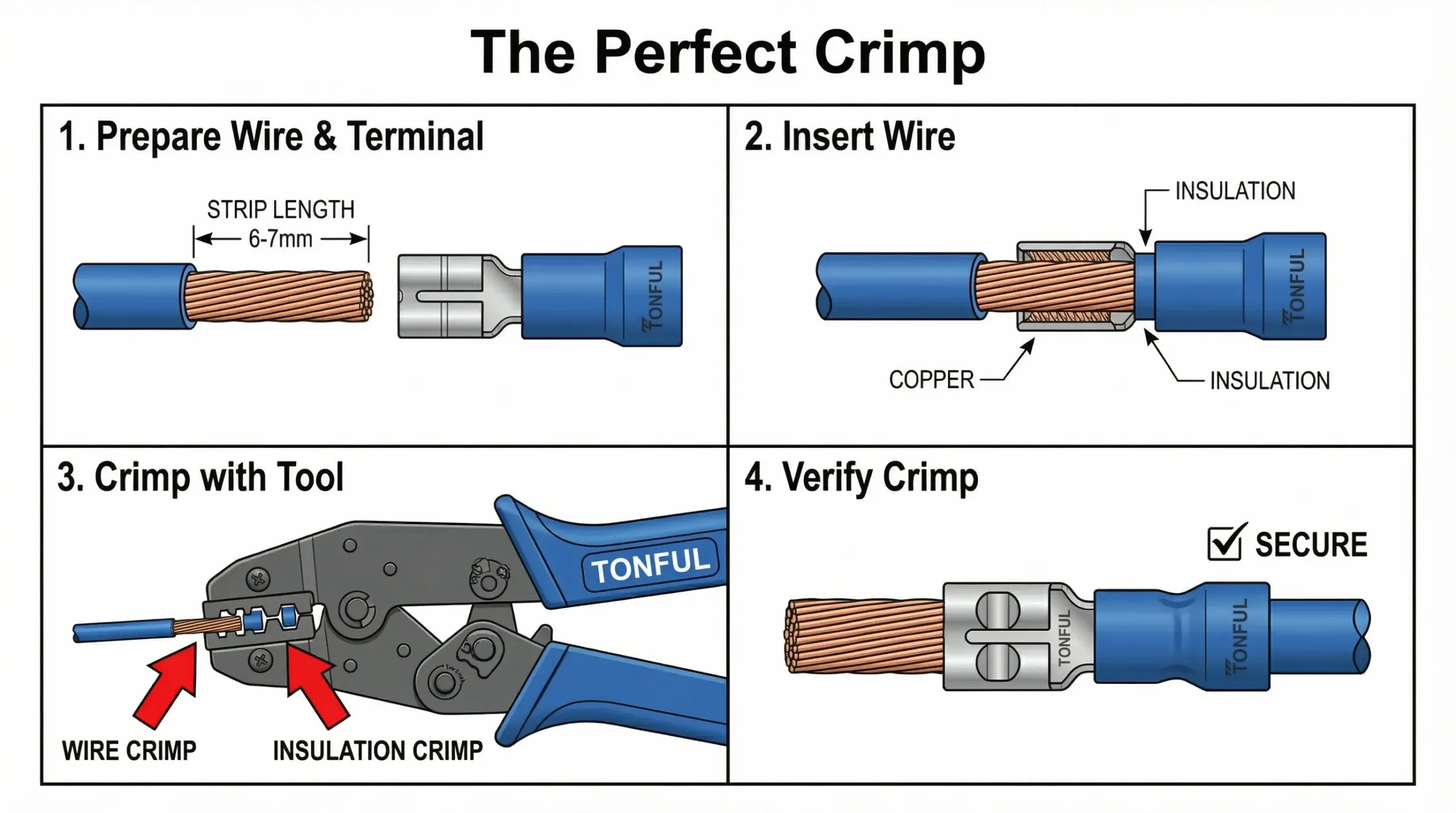

A 4-step diagram showing the correct process for crimping a TONFUL quick disconnect terminal for a secure connection.

Critical Industrial Applications

The versatility of quick disconnect terminals makes them ubiquitous across numerous industries. Their ability to improve manufacturing efficiency and simplify repairs is highly valued.

TONFUL quick disconnect terminals ensure reliable connections in critical industrial control systems.

Industrial Applications and Recommended Terminals

| Industry | Common Applications | Recommended TONFUL Terminals | Key Benefits |

|---|---|---|---|

| Automotive | Wiring harnesses, sensors, relays, lighting systems, switches. | Nylon, Heat Shrink | Vibration resistance, high-temperature tolerance, secure connections. |

| Industrial Machinery | Control panels, motors, solenoids, limit switches, power distribution. | Nylon, Non-Insulated (in enclosures) | Fast assembly, easy component replacement, reduced downtime. |

| HVAC | Thermostats, compressors, fans, contactors, safety switches. | Vinyl, Nylon | Serviceability, reliable connections in control circuits. |

| Marine | Navigation equipment, lighting, bilge pumps, switch panels. | Heat Shrink (mandatory) | Superior corrosion resistance and waterproof sealing against salt spray. |

| Appliances | Internal wiring for washers, dryers, refrigerators, microwaves. | Female Receptacles, Flag Terminals | Eases assembly line production and simplifies repairs by technicians. |

| Consumer Electronics | Audio speakers, power supply units, internal components. | Female Receptacles (0.187″, 0.250″) | Low cost, ease of connection for non-serviceable and serviceable parts. |

Best Practices for Selection and Installation

To ensure the long-term reliability of your electrical system, follow these best practices when working with quick disconnect terminals:

- Match the Wire Gauge: Always use the terminal color-coded for your wire’s AWG size. A loose fit results in a poor electrical connection and low pull-out strength, while a fit that is too tight can damage the wire strands.

- Select the Correct Tab Size: Ensure the female receptacle matches the male tab size (e.g., 0.250″). A mismatch will result in a loose connection or an inability to mate the parts.

- Choose the Right Insulation: Select the insulation material based on the operating environment. Use vinyl for general-purpose indoor use, nylon for high-vibration or higher-temperature applications, and heat shrink for any environment exposed to moisture, chemicals, or extreme conditions.

- Use a Quality Crimping Tool: Never use standard pliers to crimp terminals. A proper ratcheting crimp tool is designed with specific dies for insulated and non-insulated terminals, ensuring a uniform, gas-tight crimp that is both mechanically and electrically superior.

- Inspect the Connection: After crimping, give the wire a firm tug to ensure it is secure. Visually inspect the insulation to ensure the crimper has not pierced it (unless it’s an insulation displacement type) and that the wire is securely held by the strain relief crimp.

A close-up of a waterproof TONFUL heat shrink quick disconnect terminal with water droplets on it, installed in a harsh marine environment.

Frequently Asked Questions (FAQ)

Q1: What is the difference between a spade terminal and a quick disconnect terminal?

A: The terms are often used interchangeably. “Spade terminal” typically refers to the forked or blade-like shape, while “quick disconnect” refers to the function of easily connecting and disconnecting. Most quick disconnects are a type of spade terminal.

Q2: Can I reuse quick disconnect terminals?

A: Yes, the male/female connection is designed to be mated and unmated multiple times. However, the crimped connection to the wire is permanent. If you need to change the wire, you must cut off the old terminal and crimp a new one.

Q3: Why are the terminals different colors?

A: The colors on insulated terminals are standardized to indicate the wire gauge (AWG) range they are designed for. Red is for 22-18 AWG, Blue is for 16-14 AWG, and Yellow is for 12-10 AWG. This prevents mismatches and ensures a proper connection.

Q4: What tool should I use to install these terminals?

A: Always use a dedicated crimping tool designed for the type of terminal you are using (insulated or non-insulated). These tools apply uniform pressure to create a reliable crimp without damaging the terminal or wire, unlike pliers which can create a weak, unreliable connection.

Q5: When is it essential to use a heat shrink terminal?

A: Heat shrink terminals are essential in any application exposed to moisture, dust, chemicals, or high vibration. This includes marine, automotive (especially in the engine bay), off-road vehicles, and outdoor industrial equipment. The adhesive-lined tubing creates a waterproof seal that protects the connection from corrosion and failure.

TONFUL quick disconnect terminals organized on an automotive assembly line workstation, demonstrating efficient high-volume manufacturing.

Why Choose TONFUL Electric Quick Disconnect Terminals?

Choosing the right electrical component is critical, but choosing the right manufacturing partner is paramount. At TONFUL Electric, we understand that the integrity of your entire system can depend on a single connection. That is why we are committed to being more than just a supplier; we are your partner in achieving manufacturing excellence and long-term reliability.

- Commitment to Quality: Our quick disconnect terminals are manufactured under strict quality control processes to meet rigorous industrial standards. We utilize high-grade materials, such as tinned brass and copper, for maximum conductivity, corrosion resistance, and crimp strength, ensuring every connection is secure and durable.

- Comprehensive Portfolio: We offer a vast selection of terminals to meet any application requirement. From general-purpose vinyl and high-durability nylon to fully waterproof heat shrink terminals, TONFUL provides a complete range of insulation types, styles (female, male, flag, piggyback), and standard tab sizes from 0.110″ to 0.312″.

- Proven Industrial Reliability: TONFUL terminals are engineered for the demanding conditions of modern industry. They provide consistent performance in high-vibration automotive environments, corrosive marine settings, and high-volume manufacturing lines, reducing downtime and ensuring the safety and longevity of your products.

- Expert Technical Support: Our in-house team of electrical engineers and product specialists possesses deep knowledge of terminal technology and applications. We are ready to provide expert consultation to help you select the ideal terminal for your specific design and environmental challenges.

Elevate the quality and efficiency of your electrical assemblies. Contact TONFUL Electric today to request a quote for bulk orders, discuss your custom requirements, or consult with our technical experts. Build with confidence, build with TONFUL.