What is a Spade Terminal (Fork Terminal)?

Technically, the term “spade terminal” refers to a connector with an open, fork-like shape. This design allows it to be slipped under a screw or stud without completely removing the fastener. This makes installation and removal faster than with a ring terminal, especially in tight spaces.

Despite the clear technical definition, there’s a common industry-wide confusion. Many professionals colloquially use “spade connector” to refer to the male half of a quick disconnect terminal. For clarity in this article, we will refer to the fork-shaped connectors as spade terminals or fork terminals, and the blade-and-receptacle style as quick disconnects.

An assortment of high-quality TONFUL spade terminals and quick disconnects, showcasing different insulation types and materials on an industrial workbench.

Types of Spade Terminals

Spade terminals come in several variations to suit different security needs:

- Standard/Block Spades: The most common type with a simple fork shape.

- Flanged/Locking Spades: The tips of the fork are bent upwards. This design helps prevent the terminal from slipping out from under the screw head, providing extra security against vibration.

- Captive Spades: A feature recommended by standards like ABYC E-11 for marine applications, where the prongs are designed to “capture” the stud, making them almost as secure as a ring terminal.

What is a Quick Disconnect Terminal?

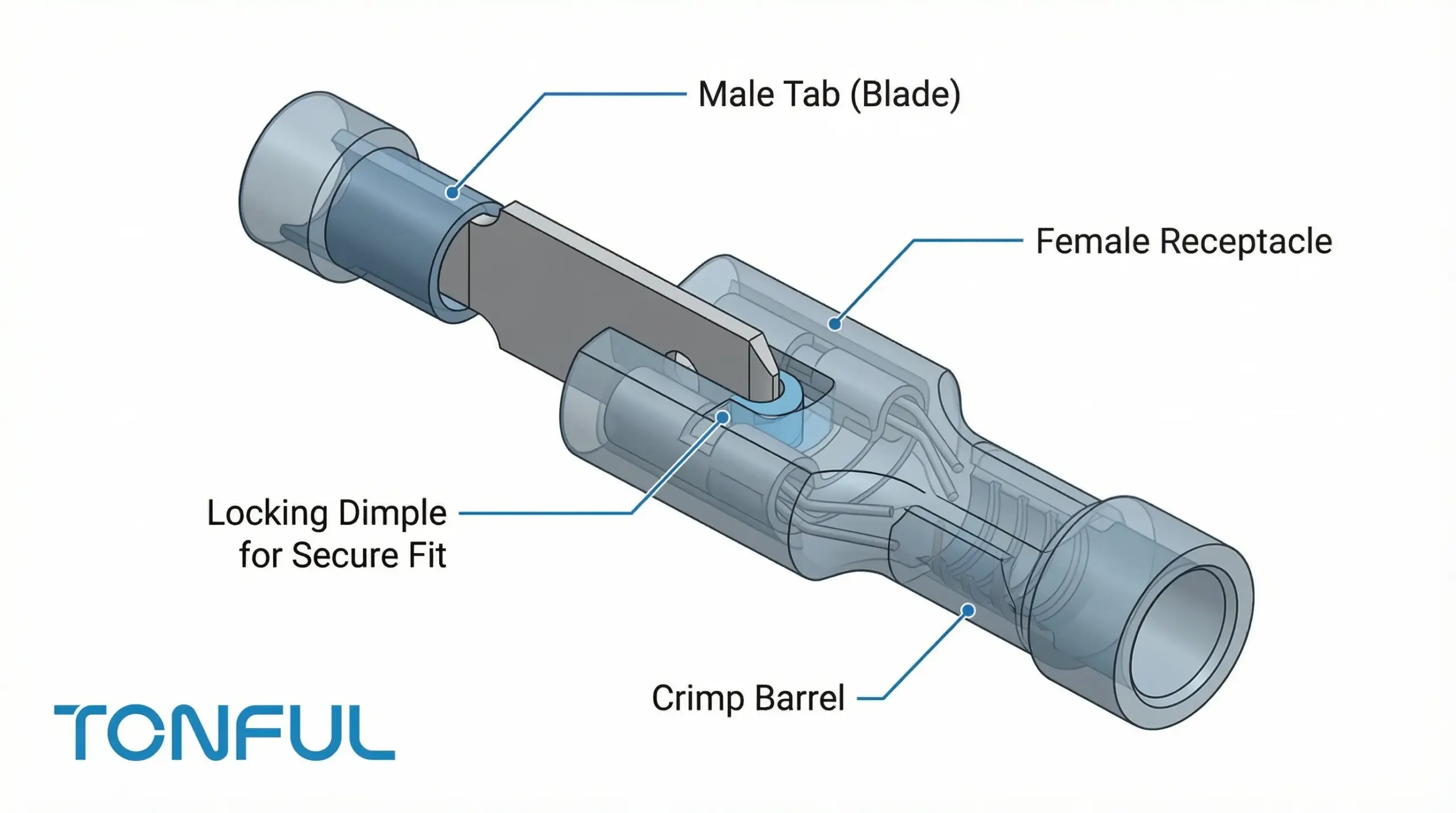

A quick disconnect terminal, also known by the TE Connectivity trademark “FASTON terminal,” is a two-piece connector system. It consists of a male blade (or tab) and a female receptacle. The connection is made by simply pushing the two halves together, creating a secure, friction-based electrical path that can be easily pulled apart for service or replacement.

This “plug-and-play” functionality is their defining feature, making them indispensable in mass production and for components that require frequent maintenance.

Types of Quick Disconnects

- Male/Female: The fundamental pairing.

- Fully Insulated: Both the male and female terminals have a complete nylon or PVC housing, preventing any accidental contact and short-circuiting when mated.

- Partially Insulated: Insulation covers the crimp barrel but leaves the connection point exposed.

- Non-Insulated: Bare metal terminals used where insulation is provided by other means or is not required.

- Piggyback: A type of female receptacle that also includes a male tab, allowing you to “stack” connections on a single terminal point.

- Flag Terminals: The female receptacle is oriented at a 90-degree angle to the wire, ideal for tight spaces where a straight connection isn’t feasible.

Spade Terminals vs. Quick Disconnects: Head-to-Head Comparison

To understand which connector is right for your project, a direct comparison is essential.

| Feature | Spade Terminal (Fork Type) | Quick Disconnect Terminal (Blade/Receptacle) |

|---|---|---|

| Connection Mechanism | Slips under a screw or stud. | Male blade slides into a female receptacle. |

| Security | Good. Dependent on screw torque. Can loosen under vibration unless a locking/flanged type is used. | Moderate to Good. Relies on friction and a locking dimple. Connection force can degrade over multiple cycles. |

| Installation | Fast. The screw only needs to be loosened, not removed. Requires a crimping tool. | Very fast. Simple push-to-connect action. Requires a crimping tool. |

| Removal / Service | Fast. Loosen screw and slide out. | Very fast. Simple pull-to-disconnect. Ideal for modular components. |

| Reusability / Mating Cycles | High. The terminal itself doesn’t wear, but the wire connection is permanent. | Limited. Rated for a certain number of connect/disconnect cycles before connection force degrades. |

| Vibration Resistance | Moderate. Standard spades can loosen. Flanged and captive types offer much better performance. | Moderate. Prone to fretting/loosening in high-vibration environments without a positive locking feature. |

| Space Requirement | Excellent for accessing screw terminals in confined areas. | Requires clearance to plug and unplug the connection. Flag versions help in tight spots. |

| Typical Applications | Terminal blocks, bus bars, grounding connections, component screw-down points. | Wiring harnesses, relays, switches, speakers, motors, lights, and modular equipment. |

| Industry Standards | Often falls under general terminal standards. ABYC E-11 for marine use. | UL 310 is the specific standard for Quick-Connect Terminals. |

Installation Best Practices: The Crimp is Key

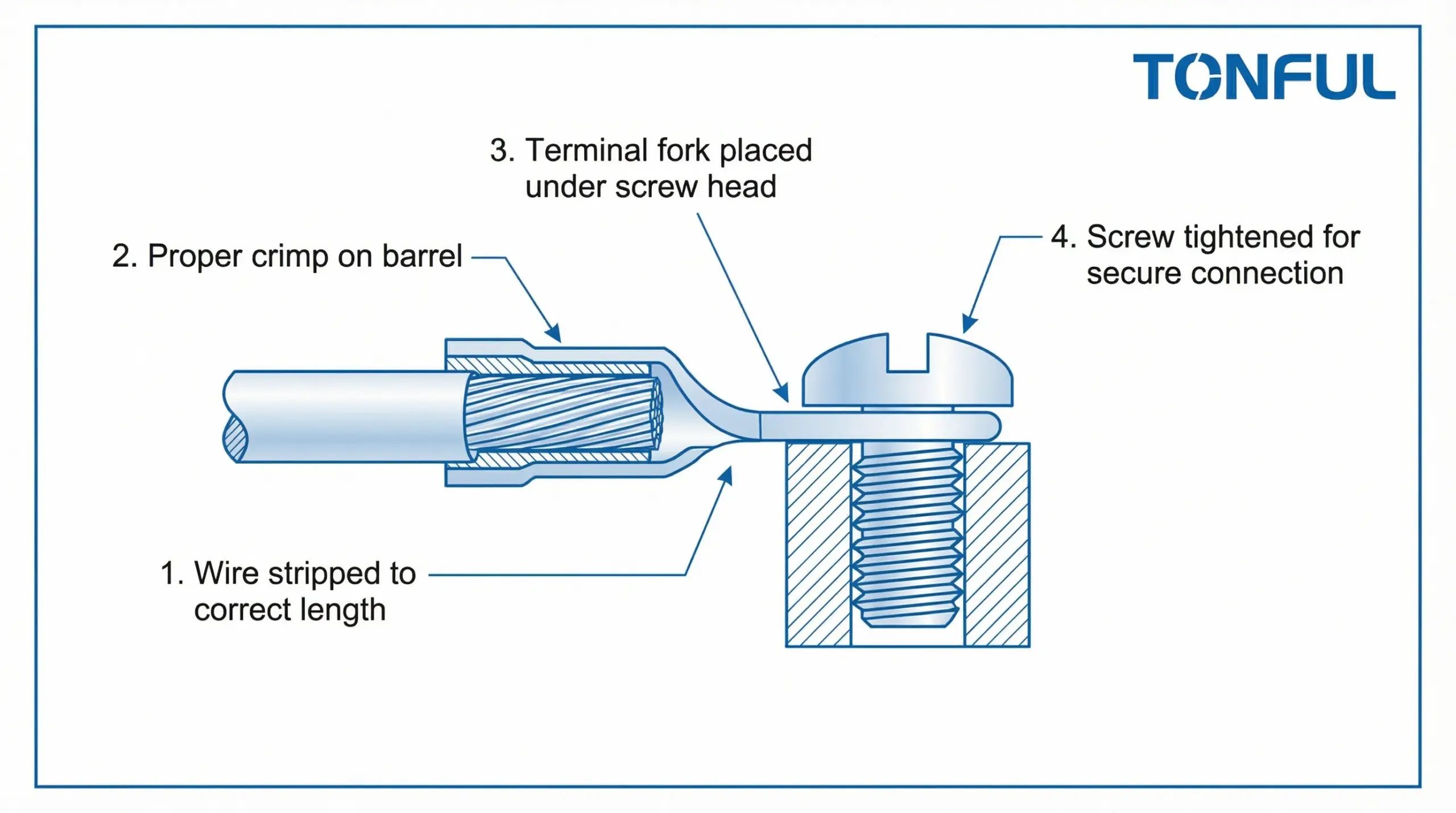

Regardless of the terminal type, the integrity of the connection depends almost entirely on the quality of the crimp. A poor crimp leads to high resistance, heat generation, and eventual failure.

Technical diagram showing the correct installation procedure for a TONFUL spade terminal onto a screw terminal.

Steps for a Perfect Crimp:

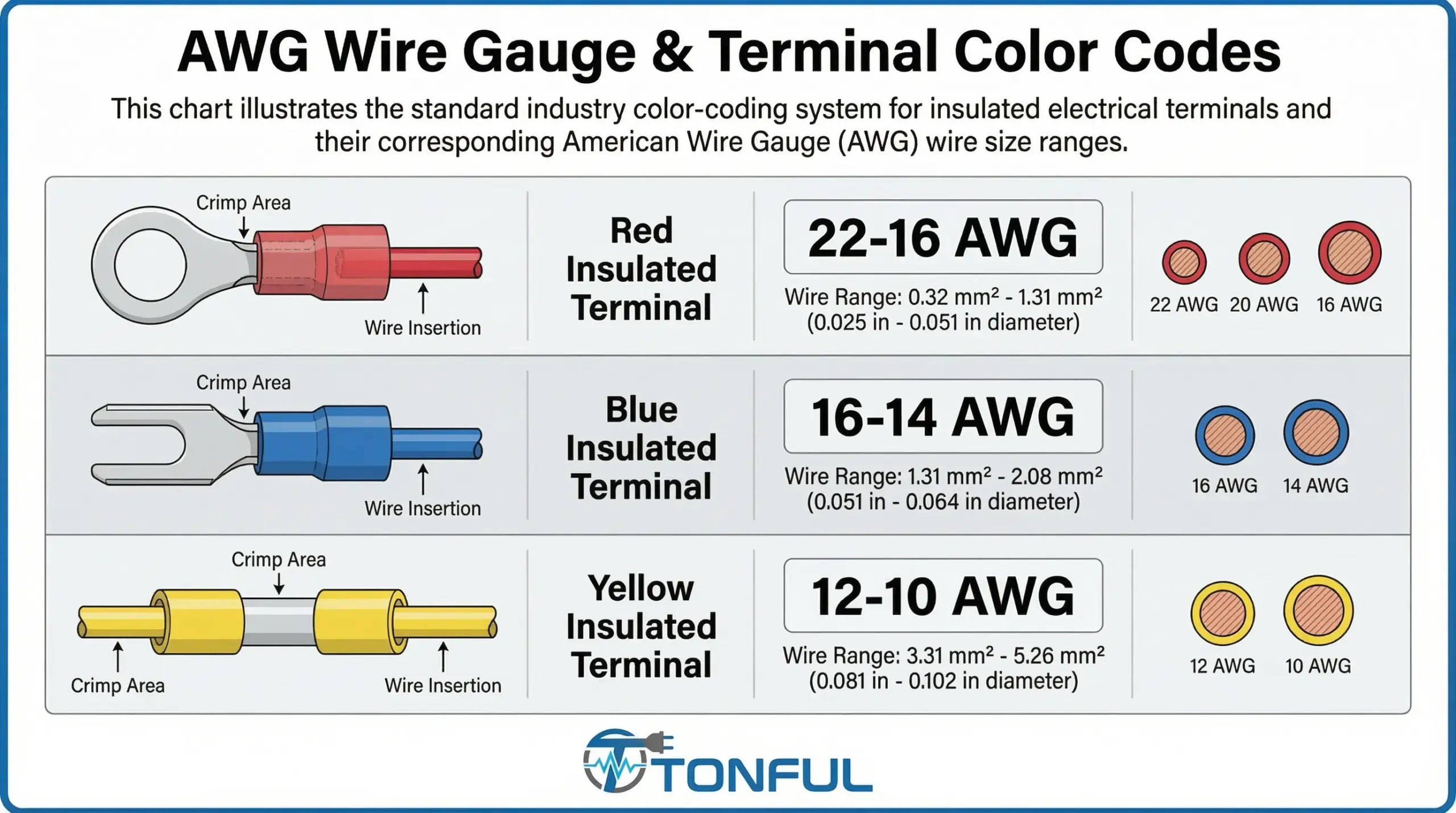

- Select the Right Terminal: Ensure the terminal’s wire gauge range matches your wire. Use the industry-standard color code as a guide.

- Strip the Wire: Strip the wire insulation to the length specified for the terminal. Too short, and the crimp won’t be secure; too long, and you risk exposed wire.

- Use the Correct Tool: NEVER use standard pliers. Use a dedicated ratcheting crimper designed for insulated or non-insulated terminals. The tool should have nests that match the terminal size/color.

- Crimp: Place the terminal in the correct nest and insert the stripped wire. Squeeze the crimper until its ratchet mechanism releases. This ensures a full, proper crimp every time.

- Inspect: Give the wire a firm tug. It should not pull out of the terminal. The insulation should be secure and not damaged.

Annotated technical diagram illustrating the mating mechanism of a TONFUL male and female quick disconnect terminal.

Application Guide: Where to Use Each Connector

The choice between a spade terminal and a quick disconnect is driven by the application’s need for security versus serviceability.

Automotive

- Quick Disconnects: Heavily used for connecting components like headlights, taillights, speakers, sensors, and relays. Their modularity is perfect for assembly lines and simplifies repairs.

- Spade Terminals: Used on terminal blocks and grounding studs where a semi-permanent connection is needed.

A technician making a secure connection with a TONFUL quick disconnect terminal inside an industrial electrical control panel.

Industrial Control Panels

- Quick Disconnects: Ideal for modular components like power supplies, relays, timers, and switches. They allow for rapid troubleshooting and replacement of faulty parts, minimizing downtime.

- Spade Terminals: Excellent for wiring to terminal strips and bus bars where connections are less frequently disturbed. Their ability to be installed without fully removing screws is a major time-saver during panel construction.

Marine Environments

- Spade Terminals: Captive or flanged spade terminals are often used as an alternative to ring terminals, as recommended by ABYC standards. They must be made of tin-plated copper to resist corrosion. Heat shrink insulation is critical for environmental sealing.

- Quick Disconnects: Used with caution in protected, low-vibration areas. Environmental sealing (using heat shrink versions) is paramount to prevent moisture intrusion and corrosion, which can quickly degrade the connection.

Appliances & HVAC

- Quick Disconnects: The dominant choice inside everything from washing machines to air conditioning units. They drastically speed up factory assembly and make in-field servicing by technicians much more efficient.

Materials and Standards Matter

The performance of a terminal is defined by its materials.

- Conductor: High-conductivity copper is the base. For harsh environments, tin-plated copper is the gold standard, offering excellent corrosion resistance. Brass is a common, lower-cost alternative suitable for dry, stable environments.

- Insulation:

- Vinyl (PVC): The standard, cost-effective choice for general-purpose use.

- Nylon: Offers a higher temperature rating and superior resistance to hydrocarbons (oil, gasoline), making it ideal for automotive and industrial use.

- Heat Shrink: Provides the ultimate protection. When heated, it shrinks to form a waterproof, environmentally sealed connection, protecting the crimp from moisture, salt, and chemicals.

A technical chart showing the industry-standard color coding for TONFUL electrical terminals corresponding to AWG wire gauge sizes.

Frequently Asked Questions (FAQ)

Q1: Is a spade terminal the same as a quick disconnect?

Technically, no. A “spade terminal” is a fork-shaped connector for a screw stud. A “quick disconnect” is a male blade and female receptacle system. However, in common language, the male blade of a quick disconnect is often called a spade connector. It’s important to clarify which type you need when ordering.

Q2: Can I use pliers to crimp terminals?

No. Pliers create an improper, weak crimp that will fail. You must use a dedicated ratcheting crimping tool that is designed for the specific type and size of terminal you are using to ensure a mechanically strong and electrically sound connection.

Q3: When should I use a spade terminal over a ring terminal?

Use a spade terminal when you need to connect to a screw terminal block where removing the screw completely is difficult or time-consuming. However, for maximum security and vibration resistance (e.g., a main battery ground), a ring terminal is always the superior choice because it cannot slip out unless the screw is fully removed.

Q4: What does the color of the insulation mean on a terminal?

The color is an industry-standard code for the wire gauge (AWG) the terminal is designed for:

- Red: 22-16 AWG

- Blue: 16-14 AWG

- Yellow: 12-10 AWG

Q5: How many times can I connect and disconnect a quick disconnect terminal?

This varies by manufacturer and quality. High-quality quick disconnects are designed for a limited number of mating cycles. Over time, the spring force in the female receptacle can weaken, leading to a less secure connection. For connections that must be made and unmade very frequently, a more robust plug and socket connector may be a better choice.

Conclusion: The Right Connector for the Right Job

The debate between spade terminals and quick disconnects isn’t about which is better, but which is right for the application.

- Choose Spade (Fork) Terminals for semi-permanent connections to screw terminals and bus bars, especially where installation speed is a factor. Opt for flanged or captive types in any application subject to vibration.

- Choose Quick Disconnect Terminals for modular components that require fast assembly or frequent servicing, such as relays, switches, and lights.

Ultimately, the safety and longevity of your electrical system depend on using high-quality components installed with the correct tools and techniques. Compromising on either can lead to costly failures down the line.

For high-quality, reliable spade terminals and quick disconnects that meet rigorous UL and RoHS standards, explore the TONFUL Electric product catalog or contact our engineering experts today to find the perfect solution for your application.