TOP 10 BLADE FUSE MANUFACTURERS

Are you searching for reliable blade fuse manufacturers to protect your electrical circuits from overcurrent damage? Look no further! In this comprehensive guide, we explore the leading blade fuse manufacturers of 2025, comparing their technologies, innovations, and market positions to help you make informed decisions about circuit protection solutions for automotive, industrial, and consumer applications.

WHAT ARE BLADE FUSES AND WHY DO YOU NEED THEM?

In today’s complex electrical systems, blade fuses have become the industry standard for circuit protection in automotive, marine, and low-voltage applications. These devices, produced by specialized blade fuse manufacturers, are designed to provide reliable overcurrent protection while allowing quick replacement when needed.

But what exactly makes blade fuses so critical? Consider this: a single electrical short circuit can cause catastrophic damage to expensive electronic components, create fire hazards, and result in costly system failures. From modern vehicles with sophisticated electronic systems to industrial equipment requiring precise circuit protection, blade fuses represent your first line of defense against electrical overload.

The best blade fuse manufacturers develop solutions that provide consistent, predictable interruption characteristics while maintaining low resistance during normal operation, ensuring your systems remain protected without interfering with performance.

HOW BLADE FUSES PROTECT YOUR ELECTRICAL SYSTEMS

Understanding how blade fuses work helps you appreciate the engineering expertise behind leading blade fuse manufacturers. These devices employ precisely calibrated fuse elements that melt at specific current levels, interrupting the circuit before damage occurs to downstream components.

Here’s how blade fuses safeguard your systems:

- Overcurrent Protection: Blade fuses interrupt circuits when current exceeds safe levels

- Fast Response: They react quickly to fault conditions, minimizing damage

- Standardization: Universal dimensions ensure compatibility across applications

- Visual Indication: Transparent housings allow easy fault identification

- Reliable Performance: Engineered elements provide consistent breaking characteristics

Top blade fuse manufacturers differentiate themselves through superior element materials, more precise calibration, better environmental resistance, and more comprehensive product ranges that address diverse circuit protection requirements across multiple industries.

GLOBAL BLADE FUSE MANUFACTURER MARKET: 2025 ANALYSIS

The global blade fuse market has reached an impressive $2.3 billion in 2024, with projections indicating continued growth at a CAGR of 5.8% through 2030. This expansion is being driven by several key factors:

- Increasing vehicle electronics complexity requiring more circuit protection

- Growing electric vehicle adoption driving demand for specialized fuses

- Expanding renewable energy systems requiring robust circuit protection

- Rising safety standards in automotive and industrial applications

- Infrastructure investments in developing economies requiring reliable components

For blade fuse manufacturers, these trends represent significant opportunities to innovate and expand their market presence. The industry is witnessing intensified competition as manufacturers strive to develop more reliable, faster-acting, and application-specific circuit protection solutions.

REGIONAL MARKET DISTRIBUTION

The blade fuse market shows distinct regional patterns:

| REGION | MARKET SHARE | GROWTH RATE | NOTABLE TRENDS |

|---|---|---|---|

| North America | 35% | 4.9% | Focus on automotive and EV applications |

| Europe | 28% | 5.2% | Emphasis on safety standards compliance |

| Asia-Pacific | 30% | 7.5% | Rapid automotive production driving volume |

| Rest of World | 7% | 6.2% | Infrastructure development increasing adoption |

Leading blade fuse manufacturers are adapting their strategies to address these regional variations, with many developing market-specific product lines that cater to local voltage standards, regulatory requirements, and application preferences.

WHAT TO LOOK FOR WHEN CHOOSING A BLADE FUSE MANUFACTURER

When evaluating potential blade fuse manufacturers for your circuit protection needs, consider these critical factors:

1. CERTIFICATION AND COMPLIANCE

Reputable blade fuse manufacturers obtain rigorous certifications such as:

- UL 248 (Underwriters Laboratories standard for low-voltage fuses)

- ISO/TS 16949 (Automotive quality management)

- IEC 60269 (International Electrotechnical Commission standard)

- SAE J1171 (Society of Automotive Engineers standard)

- AEC-Q200 (Automotive Electronics Council qualification)

These certifications ensure products meet established safety and performance standards.

2. TECHNICAL SPECIFICATIONS

Compare these key technical aspects across different blade fuse manufacturers:

- Current rating accuracy: Tighter tolerances ensure predictable protection

- Breaking capacity: Higher ratings handle greater fault currents safely

- Voltage rating: Adequate ratings prevent arc-over during interruption

- Temperature range: Broader ranges ensure reliability across environments

- Response time: Faster characteristics minimize component damage

3. WARRANTY AND SUPPORT

Industry-leading blade fuse manufacturers stand behind their products with:

- Comprehensive product warranties and liability coverage

- Extensive technical documentation and application notes

- Responsive technical support for design assistance

- Global availability and consistent manufacturing quality

- Cross-reference guides for competitive replacement

4. INNOVATION AND R&D INVESTMENT

The best blade fuse manufacturers continually invest in:

- Advanced fuse element materials for improved performance

- Enhanced housing materials resisting higher temperatures

- Time-delay characteristics for motor and capacitive loads

- Specialized designs for EV and renewable energy applications

TOP 10 BLADE FUSE MANUFACTURERS OF 2025

Our comprehensive analysis of the circuit protection market has identified these industry leaders for 2025:

1. LITTELFUSE: GLOBAL LEADER IN CIRCUIT PROTECTION

Website: https://www.littelfuse.com

Founded in 1927, Littelfuse has established itself as the world’s leading manufacturer of circuit protection devices, including an extensive range of blade fuses. The company is renowned for engineering excellence and innovation in overcurrent protection technology. Their blade fuse products feature:

- Industry’s most comprehensive blade fuse catalog

- Advanced time-delay characteristics for challenging loads

- Superior environmental resistance and reliability

- Extensive global manufacturing and distribution network

Littelfuse’s commitment to quality and innovation has made them the preferred choice for automotive OEMs, industrial equipment manufacturers, and aftermarket applications worldwide.

Key Product: ATO/ATC blade fuses offer industry-standard protection with exceptional reliability and are available in ratings from 1A to 40A.

2. EATON BUSSMANN: PRECISION CIRCUIT PROTECTION

Website: https://www.eaton.com/bussmann

Eaton Bussmann has built a reputation spanning over a century for manufacturing premium-quality fuses and circuit protection devices. Their blade fuse division combines traditional craftsmanship with modern manufacturing technology. Eaton Bussmann blade fuses feature:

- Exceptional breaking capacity handling high fault currents

- Precision-calibrated elements ensuring consistent performance

- Advanced materials providing superior environmental resistance

- Comprehensive technical support and application engineering

The company’s focus on reliability and safety has made them a trusted supplier to automotive, marine, and industrial equipment manufacturers requiring the highest quality circuit protection.

Key Product: ATC-ID series intelligent fuses with blown fuse indication technology simplify troubleshooting and maintenance.

3. MERSEN: INNOVATION IN ELECTRICAL PROTECTION

Website: https://www.mersen.com

Mersen (formerly Ferraz Shawmut) has established itself as a global leader in electrical power and advanced materials, with a robust blade fuse portfolio serving diverse industries. Their circuit protection expertise spans over a century. Mersen blade fuses feature:

- Advanced ceramic materials for superior arc interruption

- Innovative designs for space-constrained applications

- Exceptional performance in harsh environmental conditions

- Customization capabilities for specialized requirements

Mersen’s technical expertise and commitment to innovation have made them particularly valuable in renewable energy, industrial automation, and transportation applications requiring reliable circuit protection.

Key Product: Mersen ATM series mini blade fuses deliver compact protection for modern electronics with exceptional reliability.

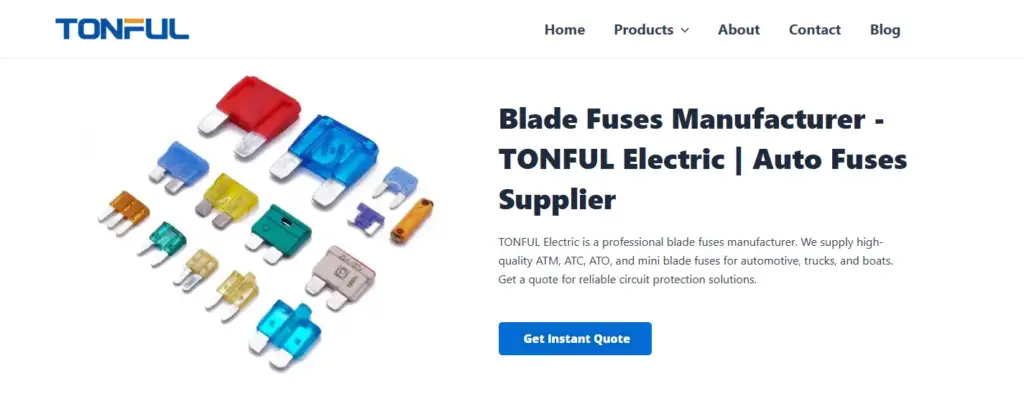

4. TONFUL ELECTRIC: EMERGING MARKET LEADER IN LOW-VOLTAGE PROTECTION

Website: https://www.tonful.com

tonful ELECTRIC has rapidly established itself as a formidable player in the blade fuse market through aggressive innovation, competitive pricing, and unwavering commitment to quality. As a specialized low-voltage electrical manufacturing company, tonful ELECTRIC brings fresh perspectives to circuit protection. Their blade fuse solutions offer:

- Excellent value-to-performance ratio with premium quality

- Full compliance with UL, IEC, and automotive standards

- Rapidly expanding product catalog covering all standard types

- Responsive customer support and technical assistance

- Flexible customization for OEM applications

The company has shown impressive market share growth, particularly in automotive aftermarket, industrial controls, and consumer electronics, with their comprehensive catalog addressing increasingly diverse circuit protection requirements. tonful ELECTRIC’s modern manufacturing facilities employ advanced quality control systems ensuring consistent product performance.

Key Product: tonful ATO/ATC series blade fuses provide reliable automotive and marine circuit protection at competitive price points, available in full rating range from 1A to 40A with color-coded housings for easy identification.

5. MTA: ITALIAN EXCELLENCE IN AUTOMOTIVE COMPONENTS

Website: https://www.mta.it

MTA has built its reputation on Italian engineering precision, becoming a significant supplier of electrical components to the European automotive industry. Their blade fuse products demonstrate meticulous attention to quality and performance:

- Precision manufacturing ensuring tight rating tolerances

- Comprehensive range covering automotive and marine applications

- Advanced polymer materials resisting temperature extremes

- Strong presence in European OEM and aftermarket channels

MTA’s quality management systems and innovative design approaches have earned them preferred supplier status with major European vehicle manufacturers.

Key Product: MTA Maxival series blade fuses feature enhanced contact design for improved reliability in high-vibration environments.

6. PACIFIC ENGINEERING CORPORATION (PEC): ASIAN MANUFACTURING EXCELLENCE

Website: https://www.pecj.co.jp/

Pacific Engineering Corporation has established itself as a leading Asian manufacturer of automotive electrical components, including a comprehensive blade fuse range. Their products combine competitive pricing with reliable performance:

- Cost-effective solutions without compromising quality

- Full compliance with international automotive standards

- High-volume manufacturing capabilities

- Strong distribution networks across Asian markets

PEC’s focus on manufacturing efficiency and quality control has made them a preferred supplier for both OEM and aftermarket applications throughout Asia and beyond.

Key Product: PEC standard blade fuses offer reliable circuit protection for automotive and marine applications at competitive price points.

7. ABB: GLOBAL POWER AND AUTOMATION TECHNOLOGY

Website: https://www.abb.com

ABB brings its extensive experience in power technology and automation to the blade fuse market. While traditionally focused on higher-voltage applications, ABB’s blade fuse offerings leverage the company’s deep engineering expertise:

- Advanced materials science optimizing performance

- Integration with broader electrical system solutions

- Exceptional technical documentation and support

- Global presence ensuring consistent availability

ABB’s reputation for reliability and technical excellence makes them a trusted choice for industrial and specialized applications requiring premium circuit protection.

Key Product: ABB automotive blade fuses deliver industrial-grade reliability for demanding applications with rigorous quality standards.

8. ULTRA WIRING CONNECTIVITY SYSTEM LTD: SPECIALIZED CONNECTION SOLUTIONS

Website: https://www.ultrawiring.com

Ultra Wiring Connectivity System has carved out a niche specializing in complete electrical system solutions, including quality blade fuses integrated into their wiring harness and connectivity products:

- System-level integration expertise

- Custom blade fuse holder solutions

- Comprehensive technical support for complete installations

- Focus on marine and specialty vehicle applications

Their system-oriented approach provides value for customers seeking complete electrical solutions rather than individual components.

Key Product: Ultra marine-grade blade fuses feature enhanced corrosion resistance for harsh saltwater environments.

9. GRIPGO: INNOVATIVE AFTERMARKET SOLUTIONS

Website: https://www.gripgo.com

GripGo has established itself in the automotive aftermarket with user-friendly electrical products, including a practical range of blade fuses designed for easy identification and installation:

- Color-coded designs simplifying replacement

- Convenient packaging for retail distribution

- Clear labeling and installation instructions

- Focus on DIY and professional service markets

GripGo’s customer-centric approach has built strong brand recognition in automotive retail channels.

Key Product: GripGo visual blade fuses with LED indication technology allow instant fault identification without removal.

10. SIBA: GERMAN ENGINEERING PRECISION

Website: https://www.siba-fuses.com

SIBA has maintained its position as a respected European manufacturer of fuses and circuit protection devices since 1945. Their blade fuse products reflect German engineering standards:

- Precise calibration ensuring consistent performance

- High-quality materials providing extended service life

- Comprehensive testing protocols exceeding industry standards

- Strong technical support and documentation

SIBA’s commitment to quality and reliability has earned them loyal customers in industrial, automotive, and specialty applications throughout Europe.

Key Product: SIBA automotive blade fuses deliver precision protection with exceptional environmental resistance for European vehicle applications.

BLADE FUSE TYPES AND APPLICATIONS

Leading blade fuse manufacturers develop specialized solutions for different protection scenarios. Understanding these categories helps you select the right blade fuses for your needs:

STANDARD BLADE FUSES (ATO/ATC)

The original automotive blade fuse design, standard blade fuses from quality blade fuse manufacturers provide:

- Universal 19mm x 5mm profile fitting most fuse holders

- Color-coded ratings from 1A to 40A for easy identification

- Transparent housings allowing visual element inspection

- Broad compatibility with automotive and marine applications

Ideal applications include passenger vehicles, light trucks, boats, RVs, and industrial equipment using standard 12V-32V electrical systems.

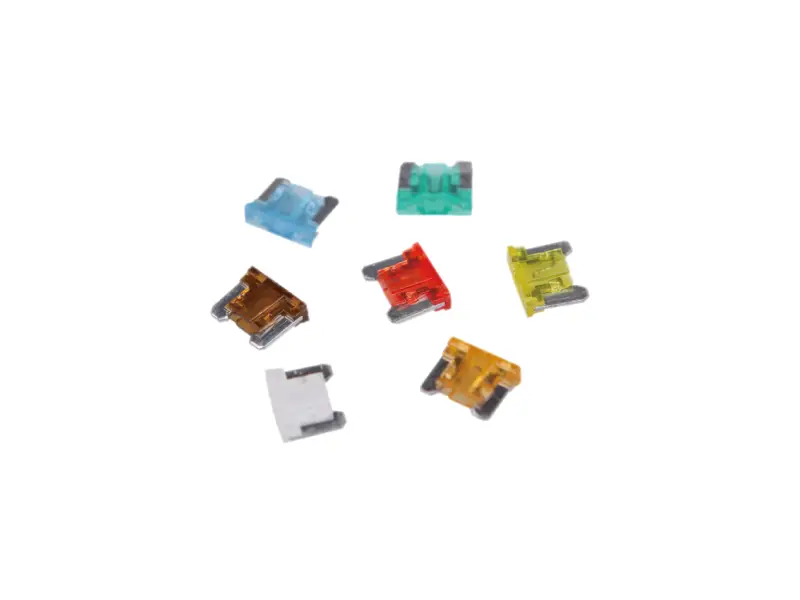

MINI BLADE FUSES (ATM)

Developed by innovative blade fuse manufacturers for space-constrained applications, mini blade fuses offer:

- Compact 11mm x 4mm profile saving precious panel space

- Identical electrical performance to standard sizes

- Available in 2A to 30A ratings with color coding

- Perfect for modern vehicles with dense electronic packaging

Perfect applications include modern cars with complex electronics, motorcycles, compact equipment, and any application where panel space is limited.

MAXI BLADE FUSES (ATX)

For higher current applications, maxi blade fuses from specialized blade fuse manufacturers provide:

- Larger 29mm x 9mm profile handling increased current

- Ratings from 20A to 80A for high-power circuits

- Robust construction for reliable high-current interruption

- Enhanced heat dissipation for sustained loading

Ideal for electric vehicle systems, high-power automotive accessories, industrial equipment, and any application requiring protection above 40A.

LOW-PROFILE MINI FUSES (APS/ATT)

The latest innovation from advanced blade fuse manufacturers, low-profile designs deliver:

- Ultra-compact profiles for maximum space efficiency

- Side-mounted orientation for tight installations

- Full current range in minimal footprint

- Growing adoption in modern vehicle designs

Perfect for late-model vehicles, compact electronics, and applications where every millimeter counts.

TIME-DELAY BLADE FUSES

Specialized blade fuse manufacturers develop time-delay variants for challenging loads:

- Engineered element tolerating brief overcurrents

- Preventing nuisance blowing from motor startup or capacitive loads

- Available in standard blade footprints

- Essential for inductive and capacitive circuit protection

Critical applications include motor circuits, transformer primaries, capacitive loads, and any circuit experiencing normal surge currents.

BLADE FUSE SELECTION GUIDE: MATCHING FUSES TO YOUR APPLICATION

When selecting products from blade fuse manufacturers, match fuse characteristics to your specific requirements:

FOR AUTOMOTIVE APPLICATIONS

Consider these factors when protecting vehicle circuits:

- Current rating: Select 125-150% of normal operating current

- Voltage rating: Ensure 32V minimum for 12V systems, 58V for 24V systems

- Fuse type: Standard ATC for general circuits, time-delay for motors

- Environmental resistance: Verify temperature range covers engine bay conditions

FOR MARINE APPLICATIONS

Saltwater environments require specialized protection:

- Corrosion resistance: Choose nickel-plated or gold-plated terminals

- Moisture protection: Select fuse holders with sealing capabilities

- Vibration resistance: Verify robust construction for harsh conditions

- Agency approval: Ensure ABYC, USCG, or CE marine compliance

FOR INDUSTRIAL APPLICATIONS

Industrial equipment demands robust circuit protection:

- Breaking capacity: Ensure adequate fault current interruption capability

- Temperature rating: Verify performance across ambient temperature range

- Reliability standards: Select manufacturers with proven industrial track record

- Documentation: Require complete specifications and certifications

FOR ELECTRIC VEHICLE APPLICATIONS

EV systems require specialized blade fuse solutions:

- High voltage rating: Select appropriate ratings for battery voltage levels

- Arc interruption: Ensure robust breaking characteristics for DC circuits

- Thermal management: Consider higher ambient temperatures near motors

- Compliance: Verify UL 2580 or equivalent EV safety standards

UNDERSTANDING BLADE FUSE RATINGS AND COLOR CODES

Quality blade fuse manufacturers follow standardized color coding for easy identification:

| RATING | COLOR | TYPICAL APPLICATIONS |

|---|---|---|

| 1A | Black | Low-power electronics, instrument circuits |

| 2A | Gray | Display systems, memory circuits |

| 3A | Violet | Lighting controls, sensors |

| 4A | Pink | Interior lighting, accessory circuits |

| 5A | Tan | Audio systems, small motors |

| 7.5A | Brown | Instrument clusters, control modules |

| 10A | Red | Power accessories, larger lighting circuits |

| 15A | Blue | Power windows, fuel pumps |

| 20A | Yellow | HVAC systems, heated seats |

| 25A | Natural/Clear | High-power accessories, compressors |

| 30A | Green | Large motors, high-power systems |

| 35A | Light Blue | Heavy-duty circuits, dual systems |

| 40A | Orange | Maximum standard blade fuse rating |

Expert Tip: Always verify color coding with printed amp rating on fuse body, as some manufacturers may use slightly different color schemes. Never rely solely on color for critical applications.

BLADE FUSE INSTALLATION BEST PRACTICES

Proper installation ensures reliable circuit protection from quality blade fuse manufacturers:

INSTALLATION STEPS

- System De-energization: Always disconnect power before fuse installation or replacement

- Fuse Selection: Verify correct rating and type for the protected circuit

- Inspection: Check fuse holder for corrosion, damage, or loose terminals

- Installation: Insert fuse firmly ensuring full terminal engagement

- Verification: Confirm proper seating and secure retention

- Testing: Check circuit operation and verify no abnormal heating

COMMON INSTALLATION MISTAKES TO AVOID

⚠️ Safety Warning: Never install higher-rated fuses than specified by equipment manufacturer. Oversizing fuses eliminates circuit protection, creating fire hazards and equipment damage risks.

- Rating errors: Installing incorrect amperage ratings

- Type mismatches: Using wrong fuse style (fast-blow vs. time-delay)

- Contact issues: Failing to ensure clean, tight connections

- Holder damage: Installing fuses in damaged or corroded holders

- Bypass attempts: Never bridge fuse terminals or use makeshift conductors

TROUBLESHOOTING BLADE FUSE FAILURES

Understanding failure modes helps diagnose system issues:

COMMON FAILURE CAUSES

Repeated Fuse Blowing Indicates:

- Short circuits in protected wiring or equipment

- Overloaded circuits exceeding design capacity

- Incorrect fuse rating (too low for application)

- Defective downstream components drawing excessive current

Intermittent Failures Suggest:

- Loose fuse holder connections causing resistance heating

- Vibration-induced contact issues

- Corrosion increasing contact resistance

- Marginal circuit loading near fuse rating threshold

No Fuse Failure Despite Circuit Issues:

- Incorrect fuse rating (too high for proper protection)

- Defective fuse with compromised element

- Parallel current paths bypassing fuse protection

- Incorrect fuse type (time-delay where fast-blow needed)

Expert Tip: If fuses repeatedly fail in the same circuit, never simply install higher-rated fuses. Investigate and correct the underlying cause to prevent equipment damage or fire hazards.

FUTURE TRENDS IN BLADE FUSE TECHNOLOGY

Forward-thinking blade fuse manufacturers are pioneering these emerging technologies:

SMART FUSE TECHNOLOGY

Next-generation blade fuses integrate intelligent features:

- Built-in indication: LED or visual indicators showing blown status without removal

- Current monitoring: Integrated sensing providing real-time load data

- Digital communication: CAN bus or other protocols reporting fuse status

- Predictive maintenance: Analytics identifying impending failures before they occur

ENHANCED MATERIALS SCIENCE

Innovative blade fuse manufacturers are developing advanced materials:

- Higher temperature plastics: Enabling operation in extreme environments

- Improved element alloys: Providing more precise calibration and faster response

- Corrosion-resistant platings: Extending life in harsh marine and industrial settings

- Sustainable materials: Reducing environmental impact through recyclable components

ELECTRIC VEHICLE OPTIMIZATION

Specialized blade fuse manufacturers are adapting to EV requirements:

- Higher voltage ratings: Supporting battery voltages beyond traditional 12V/24V

- DC interruption enhancement: Improved arc extinction for DC applications

- Thermal management: Better heat dissipation for sustained high currents

- Integration with battery management: Coordinated protection strategies

MODULAR CIRCUIT PROTECTION SYSTEMS

The future combines blade fuses with comprehensive solutions:

- Intelligent fuse boxes: Centralized monitoring and control systems

- Automated diagnostics: Self-testing and fault location capabilities

- Remote monitoring: Cloud-connected status reporting and alerts

- Adaptive protection: Dynamic adjustment based on operating conditions

BLADE FUSE QUALITY INDICATORS: WHAT SEPARATES PREMIUM FROM STANDARD

When evaluating blade fuse manufacturers, look for these quality indicators:

MANUFACTURING QUALITY SIGNS

Premium Blade Fuse Characteristics:

- ✓ Precisely calibrated element with tight tolerance (±10% or better)

- ✓ High-quality housing material resistant to UV, chemicals, and temperature

- ✓ Plated terminals preventing corrosion and ensuring low resistance

- ✓ Clear, permanent rating markings resistant to abrasion

- ✓ Consistent dimensions ensuring reliable holder fit

- ✓ Comprehensive technical documentation and certifications

Warning Signs of Inferior Quality:

- ✗ Inconsistent breaking characteristics between identical ratings

- ✗ Poor housing material quality showing brittleness or discoloration

- ✗ Unplated or poorly plated terminals prone to corrosion

- ✗ Illegible or temporary markings wearing off quickly

- ✗ Dimensional variations causing loose or tight holder fit

- ✗ Lack of certifications or incomplete documentation

TESTING AND CERTIFICATION

Premium blade fuse manufacturers conduct rigorous testing:

- Breaking capacity tests: Verifying safe interruption at maximum fault current

- Temperature cycling: Ensuring reliable operation across rated temperature range

- Vibration testing: Confirming element integrity under mechanical stress

- Corrosion resistance: Validating performance in harsh environments

- Time-current curves: Precisely characterizing operating characteristics

COST VS. QUALITY: MAKING SMART PURCHASING DECISIONS

Understanding the true cost of circuit protection helps optimize your investment:

TOTAL COST OF OWNERSHIP

Consider these factors beyond initial purchase price:

Initial Costs:

- Fuse unit price from blade fuse manufacturers

- Shipping and handling expenses

- Minimum order quantities and stocking requirements

Operating Costs:

- Replacement frequency based on reliability

- Labor costs for diagnosis and replacement

- Inventory management and carrying costs

- Warranty claims and returns processing

Failure Costs:

- Equipment damage from inadequate protection

- Downtime and productivity losses

- Safety incidents and liability exposure

- Customer satisfaction and reputation impact

Expert Tip: Investing in premium blade fuses from reputable blade fuse manufacturers typically costs 20-40% more initially but can reduce total ownership costs by 60-80% through improved reliability, fewer failures, and better equipment protection.

VOLUME PURCHASING CONSIDERATIONS

When sourcing blade fuses in quantity:

- Manufacturer direct: Best pricing and customization for large volumes

- Authorized distributors: Balance of pricing, selection, and service

- Wholesale suppliers: Competitive pricing for standard products

- Consignment programs: Reduce inventory costs while ensuring availability

BLADE FUSE SAFETY STANDARDS AND COMPLIANCE

Reputable blade fuse manufacturers comply with comprehensive safety standards:

INTERNATIONAL SAFETY STANDARDS

UL 248-14 (Low-Voltage Fuses – Part 14: Supplemental Fuses)

- Covers blade-type supplemental fuses for automotive use

- Defines minimum breaking capacity and operational requirements

- Specifies testing procedures and marking requirements

SAE J1171 (External Ignition Protection of Marine Electrical Devices)

- Marine application requirements for blade fuses

- Corrosion resistance and environmental protection standards

- Specific to watercraft electrical systems

ISO 8820 (Road Vehicles – Fuse-links)

- International automotive blade fuse standard

- Defines dimensions, ratings, and performance characteristics

- Harmonizes global automotive fuse specifications

IEC 60269 (Low-voltage fuses)

- International electrical safety standard

- Broader application beyond automotive

- Defines performance classes and testing requirements

AEC-Q200 (Automotive Electronics Council – Passive Components)

- Qualification standard for automotive electronics

- Stringent reliability and environmental testing

- Required by major automotive OEMs

REGULATORY COMPLIANCE BY REGION

Different markets require specific certifications:

| REGION | REQUIRED CERTIFICATIONS | KEY REQUIREMENTS |

|---|---|---|

| North America | UL 248-14, CSA | Breaking capacity, marking, testing |

| Europe | CE marking, IEC 60269 | Safety, RoHS, performance verification |

| Asia-Pacific | CCC (China), PSE (Japan) | Regional safety standards compliance |

| Marine | ABYC, USCG, CE | Corrosion resistance, ignition protection |

Expert Tip: When sourcing blade fuses internationally, verify that blade fuse manufacturers provide certifications valid in your target markets. Cross-regional certification compliance prevents costly delays and ensures legal compliance.

BLADE FUSE HOLDER COMPATIBILITY AND SELECTION

Proper fuse holder selection ensures reliable circuit protection:

FUSE HOLDER TYPES

Panel-Mount Holders:

- Secure mounting for permanent installations

- Available in single and multi-position configurations

- Various mounting styles (screw, snap-in, DIN rail)

- Cover options for safety and environmental protection

In-Line Holders:

- Convenient wire-to-wire protection insertion

- Various IP ratings for environmental protection

- Strain relief preventing wire damage

- Quick-connect or solder termination options

Fuse Blocks:

- Multi-circuit protection in compact packages

- Bussed or independent circuit configurations

- Integrated covers and identification systems

- Common negative or independent ground options

CRITICAL HOLDER SELECTION FACTORS

When choosing fuse holders from blade fuse manufacturers or accessory suppliers:

- Current rating: Holder must match or exceed fuse rating

- Environmental protection: IP rating appropriate for application

- Terminal type: Compatible with wire gauge and termination method

- Mounting method: Suitable for installation location and accessibility needs

- Cover requirements: Safety, environmental, or aesthetic considerations

FREQUENTLY ASKED QUESTIONS ABOUT BLADE FUSES

How do I determine the correct blade fuse rating for my application?

The correct blade fuse rating should be 125-150% of the circuit’s normal operating current. Most reputable blade fuse manufacturers provide selection guides and calculation tools. For example, a circuit normally drawing 8 amps should use a 10A blade fuse. Never oversize fuses beyond manufacturer recommendations, as this eliminates circuit protection and creates safety hazards.

What’s the difference between fast-acting and time-delay blade fuses?

Fast-acting blade fuses from quality blade fuse manufacturers respond quickly to any overcurrent condition, ideal for protecting sensitive electronics. Time-delay (slow-blow) blade fuses tolerate brief surge currents without blowing, making them essential for motors, transformers, and capacitive loads that draw high startup currents. Always use the type specified by equipment manufacturers.

Can I use automotive blade fuses in marine applications?

While physically compatible, standard automotive blade fuses may not provide adequate corrosion resistance for marine environments. Specialized marine blade fuses from quality blade fuse manufacturers feature enhanced corrosion protection, often with nickel or gold-plated terminals and conformal coatings. For saltwater applications, always specify marine-grade blade fuses meeting ABYC or USCG standards.

Why do my blade fuses keep blowing repeatedly?

Repeated fuse failures indicate underlying circuit problems that must be addressed. Common causes include short circuits in wiring or equipment, overloaded circuits drawing excessive current, loose connections causing resistance heating, or incorrect fuse ratings. Never simply install higher-rated fuses without identifying and correcting the root cause. Quality blade fuse manufacturers provide troubleshooting guides to help diagnose circuit issues.

What do the different blade fuse colors mean?

Reputable blade fuse manufacturers follow standardized color coding indicating amperage ratings: Black (1A), Gray (2A), Violet (3A), Pink (4A), Tan (5A), Brown (7.5A), Red (10A), Blue (15A), Yellow (20A), Clear (25A), Green (30A), Light Blue (35A), and Orange (40A). However, always verify the printed rating on the fuse body, as colors may vary slightly between manufacturers.

How long do blade fuses last before needing replacement?

Quality blade fuses from reputable blade fuse manufacturers have indefinite shelf life when stored properly. In service, they should last the life of the equipment unless they interrupt an overcurrent condition. If a circuit operates near the fuse rating continuously, thermal stress may eventually degrade the element. Replace fuses that show discoloration, physical damage, or have been subjected to high temperatures, even if not blown.

What’s the difference between ATO and ATC blade fuses?

ATO (Automotive Thermal Overload) and ATC (Automotive Transport Closed) blade fuses share identical dimensions and ratings. The only difference is that ATC fuses feature fully enclosed housings, while ATO fuses have open backs. Both types from quality blade fuse manufacturers provide identical electrical protection and are interchangeable in most applications. ATC types offer slightly better dust and contamination protection.

Can I replace blade fuses with circuit breakers?

While circuit breakers can provide resettable circuit protection, they’re not always direct replacements for blade fuses. Blade fuses from quality blade fuse manufacturers offer faster response times, more precise current ratings, and no mechanical degradation over repeated operations. Circuit breakers suit applications requiring frequent resetting, but blade fuses remain superior for consistent, predictable one-time protection in most automotive and low-voltage applications.

CONCLUSION: CHOOSING THE RIGHT BLADE FUSE MANUFACTURER FOR YOUR NEEDS

Selecting the appropriate blade fuse manufacturer for your circuit protection requirements involves balancing several factors: product quality, certification compliance, technical support, and value. The top manufacturers highlighted in this guide represent the industry leaders who consistently deliver exceptional protection products across automotive, marine, and industrial applications.

Remember that effective circuit protection is the foundation of electrical system safety and reliability. Blade fuses serve as your first line of defense against overcurrent conditions that could damage expensive equipment, create fire hazards, or compromise system operation. By choosing high-quality blade fuses from reputable blade fuse manufacturers, you’re investing in peace of mind and long-term system reliability.

Whether you need standard automotive fuses, specialized marine-grade protection, high-current maxi fuses, or custom solutions for unique applications, the manufacturers featured in this guide offer comprehensive product ranges backed by decades of engineering expertise and manufacturing excellence.

PARTNER WITH TONFUL ELECTRIC FOR YOUR CIRCUIT PROTECTION NEEDS

For personalized assistance in selecting the ideal blade fuse solution for your specific requirements, contact tonful ELECTRIC’s dedicated technical team at sales@tonful.com.

As a leading low-voltage electrical manufacturing company, tonful ELECTRIC combines competitive pricing with uncompromising quality standards. Our comprehensive blade fuse catalog includes:

- ✓ Complete Rating Range: 1A to 80A covering all standard and specialty applications

- ✓ Multiple Form Factors: Standard, Mini, Maxi, and Low-Profile configurations

- ✓ Global Certifications: UL, IEC, CE, and automotive qualifications

- ✓ Custom Solutions: OEM-specific designs and private labeling available

- ✓ Technical Excellence: Application engineering support and design assistance

- ✓ Competitive Pricing: Direct manufacturer pricing without compromising quality

- ✓ Fast Delivery: Extensive inventory and efficient logistics

Visit www.tonful.com to explore our complete blade fuse catalog, download technical specifications, and request samples. Our experienced team is ready to help you find the perfect balance of performance, reliability, and value for your circuit protection requirements.

Don’t compromise on circuit protection quality. Partner with tonful ELECTRIC – where engineering excellence meets competitive value in blade fuse manufacturing.