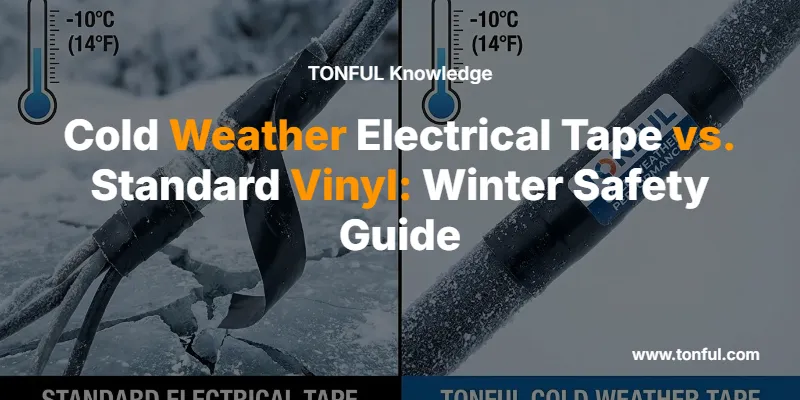

When temperatures plummet below freezing, standard electrical tape transforms from a reliable insulator into a brittle, non-adhesive liability. For maintenance professionals, facility managers, and industrial electricians working in cold climates, understanding why conventional vinyl tape fails—and what alternatives perform reliably—can mean the difference between a secure electrical connection and a costly system failure.

The Science Behind Cold Weather Tape Failure

Electrical tape is engineered with both liquid and solid adhesive components. The liquid component provides initial tack and “wetness” for surface contact, while the solid component delivers shear strength to resist removal forces. In cold temperatures, the liquid adhesive component hardens—similar to butter in a refrigerator—causing the tape to lose its essential stickiness and conformability.

Standard vinyl electrical tape typically performs optimally between 32°F and 194°F (0°C to 90°C). Below freezing, the polyvinyl chloride (PVC) backing becomes rigid and the rubber-resin adhesive loses its pressure-sensitive properties. This dual failure mode explains why tape applied in winter workshops often peels away within hours of outdoor exposure.

Temperature Performance: Standard vs. Cold Weather Formulations

The critical distinction between standard and cold-weather electrical tape lies in their plasticizer chemistry and backing material composition. Premium cold-weather formulations incorporate specialized plasticizers that maintain flexibility and adhesive tack at temperatures as low as -18°C (0°F) or even -50°F (-46°C) for advanced PVC formulations.

| Tape Type | Minimum Operating Temperature | Maximum Operating Temperature | Primary Application | UL/CSA Rating |

|---|---|---|---|---|

| Standard Vinyl (General Use) | 32°F (0°C) | 194°F (90°C) | Indoor, climate-controlled | UL 510 Listed |

| Premium All-Weather Vinyl | 0°F (-18°C) | 221°F (105°C) | Outdoor, moderate cold | UL 510 / CSA C22.2 |

| Cold-Weather PVC | -50°F (-46°C) | 221°F (105°C) | Extreme cold environments | UL 510 / CSA Certified |

| Rubber Splicing Tape | -50°F (-46°C) | 194°F (90°C) | High-voltage primary insulation | UL 510 Listed |

Professional-grade cold-weather tapes like 3M Scotch Super 33+ and Scotch Super 88 maintain conformability and adhesion across this extended temperature range, making them the industry standard for utility work, telecommunications infrastructure, and heavy equipment maintenance in cold climates.

Why Standard Vinyl Becomes Brittle in Winter

The failure mechanism of standard vinyl tape in cold weather involves three interconnected processes. First, the PVC backing loses its elasticity as polymer chains become rigid, reducing the tape’s ability to conform to irregular surfaces and cable geometries. Second, the adhesive transitions from a pressure-sensitive state to a glass-like solid, eliminating tack. Third, thermal contraction creates internal stresses that cause the tape to crack and delaminate from the substrate.

This phenomenon is particularly problematic for outdoor electrical installations, telecommunications equipment, and mobile machinery operating in northern climates. When tape is applied in a heated workshop but then exposed to sub-zero outdoor temperatures, the adhesive never achieves proper wet-out and bonding to the substrate. The result is immediate or delayed failure, often occurring precisely when electrical protection is most critical during winter storms and equipment stress.

For applications involving direct burial, cold storage facilities, or outdoor lighting systems, the temperature rating becomes a non-negotiable specification. Using tape rated only to 0°C in environments that regularly experience -20°C is not merely suboptimal—it represents a code violation and safety hazard.

Material Comparison: Vinyl vs. PVC vs. Rubber for Cold Applications

While the terms “vinyl” and “PVC” are often used interchangeably, cold-weather electrical tapes represent distinct formulation categories with different performance characteristics. Standard vinyl tape uses basic PVC backing with general-purpose rubber-resin adhesive. Cold-weather PVC tape incorporates modified polymer chains and specialized plasticizers that remain flexible at extreme low temperatures. Rubber splicing tape, manufactured from ethylene propylene rubber (EPR), offers the highest cold-weather performance but requires vinyl overwrap for UV and abrasion protection.

The selection between these materials depends on voltage requirements, environmental exposure, and mechanical stress factors. For low-voltage applications (under 600V) in moderately cold environments, premium all-weather vinyl provides the optimal balance of performance, cost, and ease of application. For primary insulation of splices in extreme cold or high-voltage scenarios, the rubber-vinyl combination system delivers superior dielectric strength and moisture sealing.

Application Best Practices for Cold Weather Installations

Proper application technique becomes even more critical when working with electrical tape in cold environments. The substrate temperature at the time of application determines whether the adhesive can achieve adequate wet-out and bonding. Industry best practice requires warming both the tape and the substrate to at least 50°F (10°C) before application, even when using cold-rated tape. This can be accomplished using heat guns, warm air blowers, or simply storing tape in an insulated container with chemical heat packs.

The wrapping technique must also be adapted for cold weather. Apply tape with 50-75% overlap (half-lapping) and sufficient tension to ensure conformability without overstretching, which can cause the backing to thin and compromise insulation thickness. For low-voltage applications, a minimum of two half-lapped layers provides adequate insulation. For splices and mechanical connections requiring primary insulation, apply four half-lapped layers of rubber tape followed by two half-lapped layers of vinyl tape for environmental protection.

After application, allow adequate dwell time for the adhesive to build bond strength before exposing the connection to mechanical stress or extreme cold. While cold-weather tape maintains initial tack at low temperatures, the adhesive system requires time to achieve full bond strength—typically 24 hours at room temperature or longer in cold conditions.

Industry Standards and Compliance Requirements

Cold-weather electrical tape must meet rigorous testing standards established by Underwriters Laboratories (UL 510) and the Canadian Standards Association (CSA C22.2 No.197). These standards specify minimum performance requirements for dielectric strength, adhesion, tensile strength, elongation, and temperature range. The temperature ratings printed on tape packaging reflect cold bend testing (determining minimum installation temperature) and continuous operating temperature limits.

Understanding the distinction between UL and CSA temperature ratings is essential for compliance. UL standards typically rate cold-weather tape to -12°C minimum, while CSA standards may specify -18°C for the same product. This difference reflects varying test methodologies rather than actual performance variation. Premium tapes carry both certifications, ensuring compliance across North American jurisdictions.

For critical infrastructure applications—including utility distribution systems, telecommunications networks, and industrial process control—using UL Listed and CSA Certified tape is not merely recommended but often required by electrical codes and insurance underwriters. The tape must also be flame retardant, meeting specific burn propagation and self-extinguishing requirements to prevent electrical fires.

Selecting the Right Cold Weather Tape for Your Application

The selection process for cold-weather electrical tape should begin with a clear understanding of the operating environment and performance requirements. Consider the minimum ambient temperature the installation will experience, the voltage rating of the circuit, the level of mechanical stress and vibration, and the exposure to moisture, UV radiation, and chemical contaminants.

For outdoor lighting systems, HVAC installations, and telecommunications equipment in regions experiencing winter temperatures between 0°F and 32°F, premium all-weather vinyl tape rated to -18°C provides reliable performance. For cold storage facilities, arctic installations, and equipment operating in extreme cold below 0°F, specialized PVC formulations rated to -50°F are essential. For high-voltage primary insulation in any cold environment, rubber splicing tape with vinyl overwrap remains the industry standard.

Brand selection matters significantly in cold-weather applications. Premium manufacturers like 3M, TONFUL Electric, and other UL Listed suppliers invest in quality control, consistent formulation, and rigorous testing. Budget-grade tapes from unknown manufacturers may claim similar specifications but often fail to deliver consistent performance, particularly in demanding environmental conditions. For professional installations where reliability is non-negotiable, specifying premium-grade tape from established manufacturers represents sound risk management.

Cost-Benefit Analysis: Premium vs. Budget Tape in Cold Climates

The price differential between standard vinyl tape and premium cold-weather formulations typically ranges from 30-50%, leading some purchasers to question whether the upgrade is justified. However, a comprehensive cost-benefit analysis reveals that premium tape delivers substantial value in cold-climate applications through reduced failure rates, lower maintenance costs, and improved safety outcomes.

Consider a typical outdoor electrical installation requiring 20 tape-wrapped connections. Using standard vinyl tape at $3 per roll might save $30 compared to premium cold-weather tape at $4.50 per roll. However, if even 10% of those connections fail during winter operation, the cost of emergency service calls, equipment downtime, and re-work easily exceeds $500-1000. For critical infrastructure where failure could cause production losses or safety incidents, the cost differential becomes negligible compared to the risk mitigation value.

Beyond direct cost considerations, premium cold-weather tape offers superior handling characteristics that improve installation efficiency. The enhanced conformability and consistent adhesion reduce application time and minimize the need for re-work. For contractors and maintenance teams working in cold conditions, these productivity gains translate to labor cost savings that often offset the material cost premium.

Common Cold Weather Tape Failures and Prevention Strategies

The most frequent failure mode in cold-weather electrical tape applications is adhesive failure—where the tape separates from the substrate without tearing. This occurs when tape is applied to cold surfaces without adequate preparation, when insufficient tension is used during wrapping, or when the tape formulation is not rated for the operating temperature. Prevention requires warming the substrate, using appropriate tape rated for the environment, and following proper application techniques.

Cohesive failure—where the tape tears or the backing splits—indicates either mechanical overstress or backing material degradation. In cold weather, standard vinyl backing becomes brittle and prone to cracking under vibration or thermal cycling. Using cold-weather PVC formulations with enhanced flexibility prevents this failure mode. For high-vibration applications like mobile equipment and reciprocating machinery, consider upgrading to rubber tape or heat-shrink tubing for superior mechanical protection.

Flagging—where tape edges lift and peel back—results from inadequate adhesion combined with wind or mechanical forces. This failure mode is particularly common in outdoor installations where tape is applied in cold conditions. The solution involves ensuring proper surface preparation (clean, dry substrate), adequate application temperature, sufficient overlap, and appropriate tape selection for the exposure conditions. For permanent outdoor installations in harsh environments, consider supplementing tape with heat-shrink terminals or molded splice kits for enhanced reliability.

Integration with Complete Electrical Systems

Cold-weather electrical tape represents just one component of a comprehensive electrical protection system. For optimal performance and code compliance, tape applications should be integrated with appropriate wire terminals, waterproof connectors, and protective enclosures rated for the operating environment.

In outdoor applications, tape-wrapped connections should be housed within NEMA-rated enclosures that provide secondary protection against moisture, UV exposure, and mechanical damage. For direct burial applications, tape alone is insufficient—use silicone-filled wire nuts or approved direct-burial splicing systems with tape providing supplementary insulation and mechanical protection.

For automotive and mobile equipment applications in cold climates, combine cold-weather tape with automotive electrical connectors featuring sealed housings and environmental seals. The tape provides strain relief and additional moisture protection while the connector delivers the primary mechanical and electrical connection. This systems approach ensures reliable performance across the full range of environmental conditions the equipment will encounter.

Frequently Asked Questions

Q: Can I use standard electrical tape if I warm it before application in cold weather?

A: Warming standard tape improves initial application, but it does not change the tape’s operating temperature rating. Once exposed to cold, standard vinyl will still become brittle and lose adhesion. For reliable cold-weather performance, use tape specifically formulated and rated for low-temperature operation.

Q: What’s the difference between UL and CSA temperature ratings on electrical tape?

A: UL (Underwriters Laboratories) and CSA (Canadian Standards Association) use slightly different test methodologies. UL typically rates cold-weather tape to -12°C minimum, while CSA may specify -18°C for the same product. Premium tapes carry both certifications. Always use the more conservative (lower) rating when selecting tape for your application.

Q: How many layers of cold-weather tape do I need for proper insulation?

A: For low-voltage applications (under 600V), apply a minimum of two half-lapped layers of premium vinyl tape. For primary insulation of splices, use four half-lapped layers of rubber tape followed by two half-lapped layers of vinyl tape for environmental protection. The total insulation thickness should be at least 1.5 times the original wire insulation thickness.

Q: Can cold-weather electrical tape be used in hot environments too?

A: Yes. Premium cold-weather electrical tape like 3M Super 33+ and TONFUL professional-grade formulations are rated for continuous operation from -18°C to 105°C (0°F to 221°F), making them suitable for both extreme cold and high-heat applications. This versatility makes them excellent all-weather choices.

Q: Does electrical tape expire or degrade in storage?

A: When stored properly in cool, dry conditions away from UV exposure, premium electrical tape maintains performance for 3-5 years. However, tape stored in unheated garages or warehouses that experience temperature cycling may degrade faster. Inspect tape before use—if the adhesive feels dry or the backing is brittle, replace it.

Q: Is cold-weather tape more expensive, and is it worth the cost?

A: Premium cold-weather tape typically costs 30-50% more than standard vinyl tape. However, the cost of a single failure—including emergency service calls, downtime, and re-work—far exceeds the material cost savings. For professional installations in cold climates, premium tape represents essential risk mitigation and is cost-effective over the system lifecycle.

Conclusion: Specifying Reliable Cold-Weather Electrical Protection

The performance gap between standard vinyl electrical tape and premium cold-weather formulations becomes critical when temperatures drop below freezing. Understanding the material science behind cold-weather failure, selecting appropriately rated products, and following proper application techniques ensures reliable electrical insulation and protection throughout winter operation.

For maintenance professionals, facility managers, and electrical contractors working in cold climates, specifying UL Listed, CSA Certified cold-weather electrical tape from reputable manufacturers like TONFUL Electric represents a fundamental best practice. The modest material cost premium delivers substantial value through reduced failure rates, improved safety outcomes, and lower total cost of ownership.

When winter weather threatens electrical system reliability, the right tape makes all the difference. Choose wisely, apply correctly, and ensure your electrical connections remain secure regardless of how low the temperature drops.

TONFUL Electric manufactures premium-grade electrical tape, wire terminals, and electrical components engineered for reliable performance in demanding environments. Our UL Listed and CSA Certified products meet the highest industry standards for safety and performance. Contact our technical team for application-specific recommendations and bulk procurement solutions.