In any robust electrical system, the integrity of the conductor is only as strong as its termination. For systems exposed to the elements—be it the persistent salt spray on a marine vessel, the bone-rattling vibration of an off-road vehicle, or the relentless humidity of an industrial washdown environment—the connection point is the most common point of failure. A poorly protected terminal can lead to intermittent faults, voltage drops, and catastrophic failure, resulting in costly downtime, equipment damage, and significant safety hazards. While standard ring terminals provide a mechanically secure connection to a screw or stud, they leave the critical crimp area exposed. This is where a superior solution becomes not just beneficial, but essential.

Heat shrink ring terminals are engineered specifically to conquer these challenges. They integrate the security of a bolted ring connection with the environmental protection of an adhesive-lined, heat-activated sealant. The result is a hermetically sealed, waterproof, and incredibly durable termination that offers unparalleled protection against moisture, corrosion, chemicals, and physical stress. This article serves as a comprehensive technical guide for engineers, technicians, and system designers who demand the utmost reliability from their electrical connections. We will explore the technical anatomy of these components, their key benefits, critical applications, and the professional installation standards required to achieve a flawless, long-lasting connection every single time.

What Are Heat Shrink Ring Terminals? A Technical Breakdown

At first glance, a heat shrink ring terminal may look like a simple component. However, its design is a sophisticated integration of materials and engineering, with each feature serving a critical purpose. Understanding this anatomy is the first step toward appreciating its value and ensuring proper selection and installation.

Anatomy of a High-Performance Terminal

A professional-grade heat shrink ring terminal consists of three primary components working in concert: a high-conductivity ring and barrel, a durable outer insulation sleeve, and a thermally activated inner adhesive lining.

- The Barrel: Electrical and Mechanical Core: The foundation of the terminal is a single piece of high-conductivity metal, typically 99.9% pure electrolytic copper. This core is designed to provide a low-resistance pathway for current and to be strong enough to form a gas-tight crimp around the wire conductor. To prevent oxidation, the copper is electro-tinned. This tin plating is crucial, as it protects the copper from corrosion (especially galvanic corrosion when connected to other metals) and ensures a reliable, low-resistance connection for the life of the system. The barrel often features a brazed seam, which prevents it from splitting open under the pressure of the crimping process, a common failure point in lower-quality, butted-seam terminals.

- The Outer Wall: Translucent Polyolefin Tubing: This is the terminal’s first line of defense against the outside world. Made from a durable, cross-linked polyolefin polymer, this tubing provides excellent dielectric strength (insulating against voltage), as well as high resistance to abrasion, common industrial chemicals, and UV radiation. Its high tensile strength allows it to shrink tightly over the connection without splitting. The translucency of the tubing is a deliberate design feature; it allows for visual inspection of the crimp and wire placement after installation, confirming that the wire is properly seated and the connection is sound.

- The Inner Wall: Heat-Activated Adhesive Liner: This is the secret to the terminal’s environmental seal. The inner surface of the tubing is coated with a proprietary polyamide co-polymer adhesive. When heated to its activation temperature (typically around 100°C / 212°F), this adhesive melts and flows into every void between the wire insulation and the terminal barrel. As the terminal cools, the adhesive solidifies, creating a powerful bond that forms a hermetic, waterproof seal. This seal is the primary barrier that prevents moisture, salt, dust, and other contaminants from reaching the metal connection and causing corrosion.

Understanding Key Technical Specifications

Selecting the correct terminal requires a clear understanding of its rated specifications. Using the wrong component can compromise the safety and reliability of the entire electrical system.

- Wire Gauge (AWG) and Color Coding: Heat shrink ring terminals are manufactured to accommodate specific ranges of wire sizes. In North America, this is measured by the American Wire Gauge (AWG) system. To simplify identification and prevent errors, these terminals follow a standardized color-coding scheme:

- Red: For smaller wires, typically 22-16 AWG.

- Blue: For mid-range wires, typically 16-14 AWG.

- Yellow: For larger wires, typically 12-10 AWG.

Always match the terminal color to the gauge of the wire you are using. Forcing a wire that is too large into a terminal will result in a weak crimp and damaged conductors, while using a wire that is too small will create a loose connection with high resistance and risk of pull-out.

- Stud Size: The ring portion of the terminal is designed to fit over a threaded stud or screw. Stud sizes are specified by the screw number (e.g., #6, #8, #10) or fractional inch diameter (e.g., 1/4″, 5/16″, 3/8″). Using a ring that is too small for the stud is impossible, but using a ring that is too large creates a loose mechanical connection. This can lead to increased electrical resistance, heat generation, and failure from vibration. Always select a terminal with a stud size that matches the fastener you are using for a snug, secure fit.

- Ingress Protection (IP) Rating: A critical specification for any component used in harsh environments is its IP rating. Heat shrink ring terminals, when properly installed, are designed to meet IP67 or even IP68 standards.

- IP67: This rating signifies that the connection is completely dust-tight (the ‘6’) and is protected against temporary immersion in water up to 1 meter for 30 minutes (the ‘7’).

- IP68: This is a more stringent rating, indicating complete dust protection (the ‘6’) and protection against long-term immersion under pressure, with the exact depth and duration specified by the manufacturer (the ‘8’). For applications involving constant submersion, seeking an IP68-rated connection is critical.

- Temperature and Voltage Ratings: Every terminal has a maximum operating temperature and voltage. A typical high-quality heat shrink terminal is rated for continuous operation from -55°C to 125°C (-67°F to 257°F) and can handle up to 600V. These ratings ensure the terminal’s materials will not degrade or fail within the demanding thermal cycles of an engine bay or the electrical stresses of an industrial power circuit.

The Unmatched Benefits of a Hermetically Sealed Connection

Choosing a heat shrink ring terminal over a basic vinyl or nylon insulated terminal is an investment in long-term reliability. The initial cost is marginally higher, but the downstream benefits in performance, safety, and reduced maintenance are substantial.

Benefit 1: Complete Environmental Sealing (Water, Dust, and Chemical Proof)

This is the primary advantage of adhesive-lined heat shrink technology. The combination of the mechanical pressure from the shrinking polyolefin and the flow of the melted adhesive creates a truly hermetic seal. This seal actively prevents the ingress of all common failure agents:

- Water and Moisture: Whether from rain, humidity, condensation, or direct submersion, the adhesive bond blocks water from wicking down the conductor strands and reaching the crimp.

- Salt Spray: For marine and coastal applications, salt is the ultimate accelerator of corrosion. A sealed connection completely isolates the copper and tin from saltwater, preventing the electrochemical reactions that destroy terminals.

- Corrosive Chemicals: In industrial settings, connections may be exposed to oils, fuels, solvents, and cleaning agents. The polyolefin material is chemically inert to most of these substances, protecting the integrity of the insulation and the seal.

By preventing corrosion, the terminal ensures a consistent, low-resistance electrical connection for years, eliminating the intermittent faults and voltage drops that plague unsealed connections.

Benefit 2: Superior Mechanical Strength and Strain Relief

Electrical connections in mobile or vibrating equipment are under constant mechanical stress. The point where the wire enters the terminal barrel is a significant weak point, as vibration and movement can cause the wire strands to fatigue and break over time.

Heat shrink ring terminals provide exceptional strain relief. As the tubing shrinks, it not only seals the connection but also forms a rigid, supportive sleeve that extends from the terminal barrel onto the wire’s insulation. This sleeve distributes bending and pulling forces over a wider area, dramatically reducing the stress concentrated at the crimp point. The result is a connection that is far more resistant to failure from:

- Vibration: From engines, motors, and road travel.

- Tension: Accidental pulling or snagging of the wire harness.

- Flexing: Repeated movement in applications like robotics or moving equipment arms.

This enhanced durability is critical in applications like commercial vehicles, marine craft, and heavy machinery where vibration is constant and unavoidable.

Benefit 3: Long-Term Electrical Integrity and Performance

A brand-new, unsealed crimp may perform perfectly on the test bench. However, over time, microscopic gaps in the crimp allow air and moisture to penetrate, leading to oxidation of the copper conductors. This oxidation layer increases the electrical resistance of the connection.

As resistance (R) increases, the heat generated by the connection for a given current (I) also increases, following the formula P = I²R. This excess heat can cause the terminal’s insulation to melt, lead to further oxidation, and create a dangerous thermal runaway cycle that can end in a fire.

Because the adhesive-lined seal prevents any air or moisture from reaching the metal components, it completely halts this degradation process. The gas-tight crimp provides the initial, high-quality electrical path, and the hermetic seal ensures it stays that way. This guarantees a stable, low-resistance, and cool-running connection for the entire service life of the equipment.

Where Heat Shrink Ring Terminals Excel: Key Applications

The unique combination of mechanical security and environmental sealing makes heat shrink ring terminals the ideal choice for a wide range of demanding applications. In these environments, the cost of failure far outweighs the cost of a premium component.

Marine and Nautical Applications: Conquering Saltwater and Vibration

Nowhere is the environment more hostile to electrical systems than on the water. The combination of constant moisture, high salinity, and engine vibration is a recipe for rapid corrosion and connection failure.

- Key Uses: Battery cable terminations, bus bar connections, navigation light wiring, bilge pump and switch wiring, and control panel connections.

- Why They Excel: The IP67/IP68-rated seal is non-negotiable in the marine world. It completely blocks corrosive salt spray and moisture, preventing the terminal from disintegrating. The superior strain relief is equally critical, protecting connections from the constant, high-frequency vibration produced by inboard or outboard motors. Using heat shrink terminals is a cornerstone of building a safe and reliable marine electrical system that complies with ABYC (American Boat and Yacht Council) standards.

Automotive and Commercial Transportation: Ensuring Reliability on the Road

From heavy-duty trucks and construction equipment to emergency vehicles and RVs, vehicle wiring harnesses are exposed to a brutal mix of vibration, temperature extremes, road salt, and engine fluids.

- Key Uses: Main power connections to alternators and starters, grounding straps, auxiliary power circuits for lights and accessories, trailer wiring harnesses, and aftermarket equipment installations.

- Why They Excel: The engine bay is a thermally dynamic environment, and the heat shrink material’s wide operating temperature range (-55°C to 125°C) ensures it remains stable and effective. The strain relief protects against constant engine vibration and chassis movement. Furthermore, the seal prevents corrosive de-icing agents (road salt) from destroying critical connections, a common cause of electrical gremlins in vehicles operating in winter climates. For fleet managers, specifying heat shrink terminals can significantly reduce vehicle downtime and costly electrical repairs.

Industrial, Outdoor, and Renewable Energy Systems

The need for robust connections extends to stationary equipment that must endure outdoor or harsh industrial conditions for decades.

- Key Uses:

- Outdoor Lighting: Streetlights, landscape lighting, and architectural lighting.

- Industrial Control Panels: In food processing plants with frequent high-pressure washdowns.

- Renewable Energy: Junction boxes for solar panels, wiring in wind turbine nacelles, and battery bank connections for off-grid systems.

- Heavy Equipment: Generators, agricultural machinery, and mining equipment.

- Why They Excel: In these long-term installations, reliability is paramount. The “install and forget” nature of a hermetically sealed connection is a massive advantage. For solar and wind installations, which are designed for a 20+ year lifespan, preventing corrosion-induced power loss is essential for maximizing energy production and ROI. In washdown environments, the IP67/IP68 seal is mandatory to prevent water intrusion and ensure operator safety.

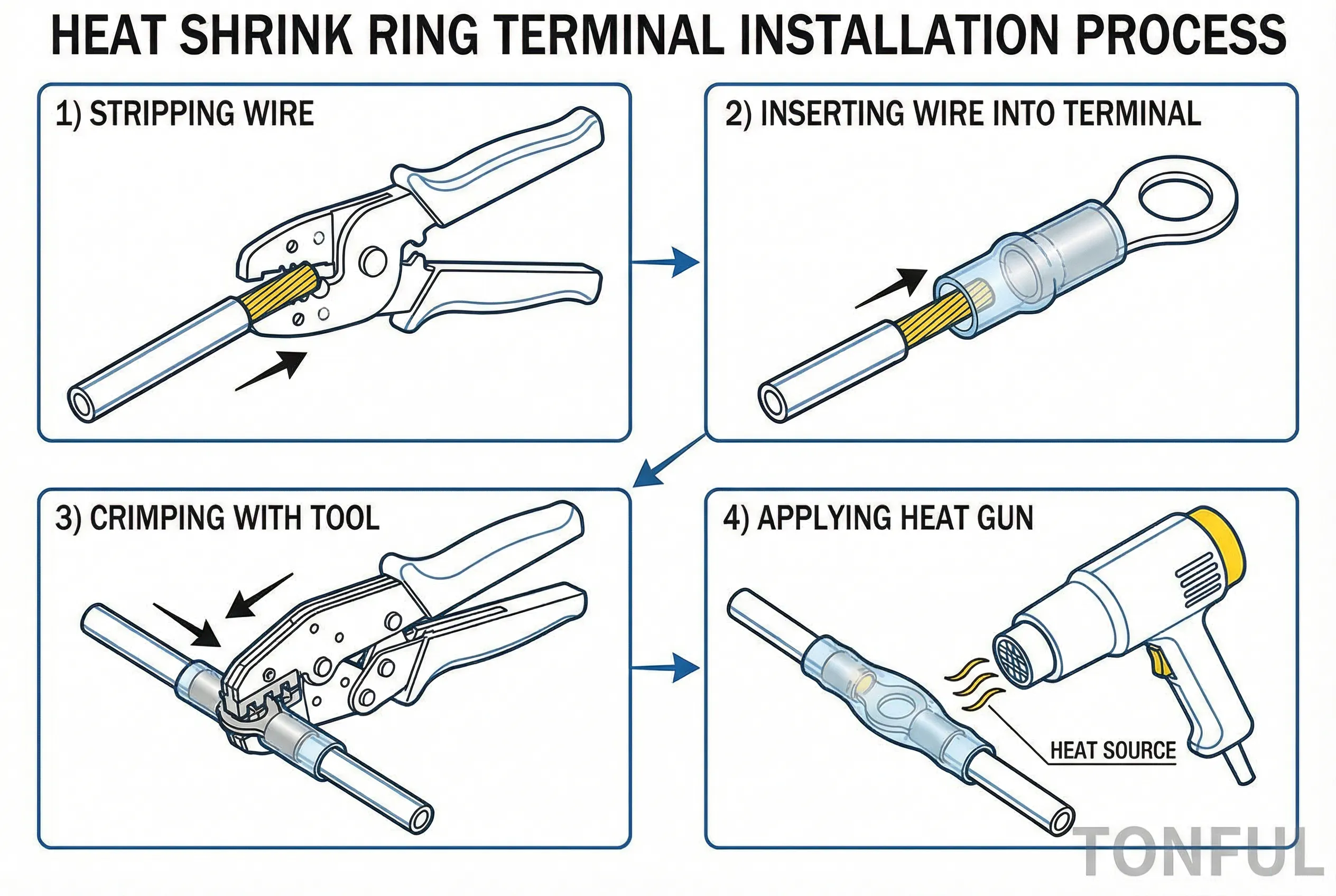

A Step-by-Step Professional Installation Guide

A heat shrink ring terminal can only provide its full benefits when installed correctly. Using the wrong tools or improper technique can lead to a false sense of security and a connection that is destined to fail. Follow these steps to ensure a perfect, professional-grade result every time.

Step 1: Preparation and Safety

- Disconnect Power: Before beginning any electrical work, ensure the circuit is completely de-energized. Disconnect the battery or turn off the corresponding breaker.

- Select the Right Terminal: Double-check that you have the correct terminal for your application. The wire gauge range (color code) must match your wire, and the stud size must match the fastener.

- Prepare the Wire: Using a quality wire stripper, remove just enough insulation from the end of the wire to allow it to be fully inserted into the terminal barrel. A common mistake is removing too much insulation, which leaves an exposed section of conductor, or too little, which prevents a proper crimp. The conductor strands should be clean and un-nicked.

Step 2: Selecting the Right Tools for the Job

Your choice of tools is as important as the terminal itself.

- Crimping Tool: Do not use standard pliers, “hammer” crimpers, or “crush” type tools. These create weak, improper crimps that will fail. You must use a dedicated ratcheting crimper designed for insulated terminals. A ratcheting crimper applies a consistent, predetermined amount of pressure to create a perfect, cold-weld connection. It will not release until the crimp is fully formed, removing guesswork and operator error. Ensure the crimper has color-coded dies that match the red, blue, and yellow terminal sizes.

- Heating Tool: Do not use an open flame like a lighter or a torch. This applies uncontrolled, excessive heat that will scorch and damage the polyolefin tubing, destroying its insulating properties and potentially burning the wire’s insulation. The correct tool is a professional heat gun with adjustable temperature settings. This allows you to apply controlled, even heat to activate the adhesive without damaging the components.

Step 3: Achieving the Perfect Crimp

A secure mechanical and electrical connection is formed by the crimp. The seal protects it, but the crimp does the work.

- Insert the Wire: Twist the conductor strands together tightly and insert them into the terminal barrel until the wire’s insulation butts up against the end of the barrel. You should not see any bare conductor outside of the terminal barrel.

- Position the Crimper: Place the terminal barrel into the corresponding color-coded die of your ratcheting crimper. The crimper’s indent should be centered on the barrel.

- Execute the Crimp: Squeeze the handles of the crimper firmly until the ratchet mechanism engages and completes its cycle, then releases. This ensures a full, proper crimp has been made.

- Perform a Pull Test: After crimping, give the wire a firm tug. It should not pull out of the terminal. If it does, your crimp was improper. Cut off the terminal and start again.

Step 4: Applying Controlled Heat for a Flawless Seal

This step transforms the connection from a standard crimp into a fully sealed unit.

- Set the Heat Gun: Set your heat gun to a medium temperature, typically around 125°C to 150°C (257°F to 302°F).

- Apply Heat Evenly: Begin heating the terminal, starting at the barrel and moving towards the end of the tubing over the wire. Keep the heat gun moving constantly, rotating around the terminal to apply heat evenly on all sides.

- Watch for the Seal: As you heat the tubing, you will see it shrink down tightly over the barrel and the wire. Crucially, you will also see a small, clear ring of adhesive begin to flow out from the wire end of the tubing. This is the visual confirmation that the adhesive has melted and created a complete waterproof seal. Once you see this clear sealant bead form, the connection is sealed.

- Avoid Overheating: Do not concentrate heat in one spot for too long. If the tubing turns dark or begins to smoke, you have applied too much heat. While the connection may still be sealed, the insulating properties of the tubing may be compromised.

Step 5: Final Inspection

Once the terminal has cooled completely (which only takes about 30 seconds), perform a final visual inspection. A perfectly installed heat shrink ring terminal will have:

- Clear tubing with no scorch marks.

- A visible ring of solidified, clear adhesive at the wire end of the tubing.

- A firm, immovable connection when tugged.

- The ring terminal securely fastened to its stud with the appropriate torque.

Frequently Asked Questions (FAQ)

1. Can I use a lighter instead of a heat gun?

No. A lighter or torch provides intense, uncontrolled heat that will damage the polyolefin tubing and can melt the wire’s insulation, compromising the entire connection. A heat gun is the only professional tool for this job as it allows for controlled temperature application.

2. What is the difference between heat shrink terminals and regular vinyl/nylon terminals?

Vinyl and nylon terminals only provide insulation. They offer no protection against moisture or corrosion, and provide minimal strain relief. Heat shrink terminals with an adhesive liner create a complete environmental seal, making them waterproof and corrosion-proof, while also providing superior strain relief and vibration resistance.

3. Are heat shrink terminals reusable?

No. The crimping and heat-shrinking process is permanent. Once a terminal is crimped and sealed, it cannot be removed and reused. If you need to remove the connection, you must cut the wire behind the terminal and install a new one.

4. Why is the tubing translucent?

The translucency is a key inspection feature. It allows you to see that the wire is fully inserted into the barrel and to visually inspect the quality of the crimp before you apply heat, ensuring a proper connection from the start.

5. How do I know I’ve heated it enough?

The definitive sign of a proper seal is seeing the clear adhesive flow and form a small bead or ring at the edge of the tubing where the wire enters. Once you see this “wetting” action occur around the entire circumference, the seal is complete.

Invest in Reliability with Tonful

In mission-critical electrical systems, a connection is never “just a connection.” It is a potential point of failure that must be engineered for maximum resilience. Heat shrink ring terminals represent the pinnacle of termination technology, offering a robust, all-in-one solution for creating connections that are mechanically strong, electrically superior, and environmentally impregnable. By preventing failures from corrosion, vibration, and moisture, you are not just buying a component; you are investing in the long-term reliability, safety, and performance of your entire system.

Whether you are building a marine-grade wiring harness, outfitting a fleet of commercial vehicles, or designing an outdoor industrial control system, choosing a high-quality, adhesive-lined heat shrink ring terminal is a decision that pays dividends for years to come. Explore Tonful’s complete range of professional-grade heat shrink terminals to find the exact solution for your application.