Premium Heat Shrink Terminals & Waterproof Electrical Connectors

TONFUL Electric is a leading Chinese manufacturer of UL-certified, dual-wall heat shrink terminals for automotive, marine, and industrial applications. Trusted by engineers worldwide for superior durability and waterproof protection.

Certified By

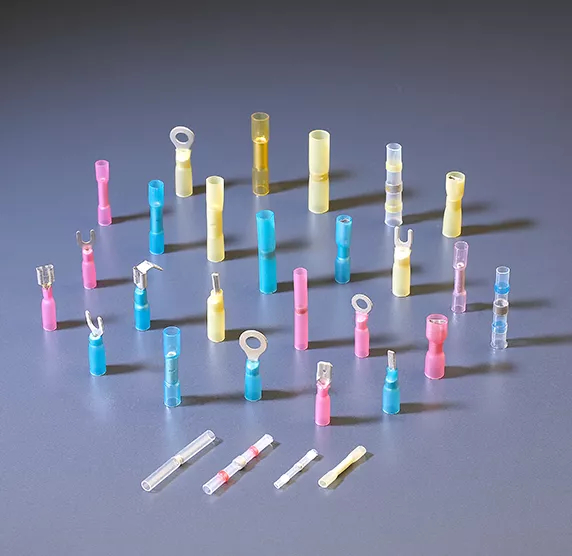

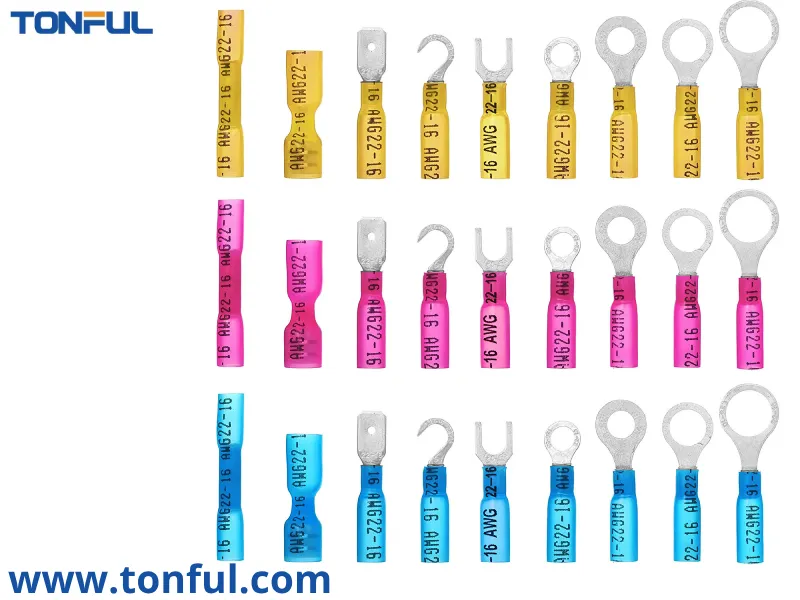

Our Heat Shrink Terminal Product Range

Heat Shrink Butt Connectors

Dual-wall solder seal design for permanent waterproof connections. Perfect for automotive wiring harnesses and marine applications. Wire Range: 0.5-6.0mm²

Heat Shrink Ring Terminals

Marine Ring Terminals Heavy-duty ring terminals with heat shrink insulation. Ideal for battery connections and grounding applications Wire Range: 1.5-16mm²

Heat Shrink Spade Connectors

Male and female spade terminals with waterproof heat shrink sleeve. Quick connect/disconnect functionality. Wire Range: 0.5-6.0mm²

Heat Shrink Fork Terminals

Secure fork connections with environmental protection. Easy installation without disconnecting wire nuts. Wire Range: 0.5-6.0mm²

Heat Shrink Terminal Kits

Complete assortment kits with mixed sizes. Convenient storage case included for professional applications. Contents: 200+ piece assortment

Custom OEM Solutions

Tailored heat shrink terminals for specific applications. EV charging, solar panels, and industrial machinery solutions. MOQ: Custom quantities available

Why Choose TONFUL Heat Shrink Terminals?

Our heat shrink terminals deliver superior performance with advanced dual-wall technology and comprehensive certifications

Superior Waterproof Protection

Dual-wall design with hot-melt adhesive creates impermeable seal against moisture, dust, and corrosion. Perfect for marine and outdoor applications.

Extreme Temperature Range

Reliable performance from -40°C to +125°C. Flame retardant materials meet UL94 V0 standards for automotive and aerospace applications.

Vibration Resistant Design

Reinforced construction prevents wire fraying and maintains secure connections under stress. Ideal for automotive and industrial machinery.

Easy Installation

Quick heat shrinking with standard heat gun. Color-coded options simplify wire identification and organization during installation.

Wide Compatibility

Supports wire gauges from 0.5mm² to 16mm². Custom OEM/ODM solutions available for specialized applications like EV batteries.

Certified Quality

UL, RoHS, CE, and ISO 9001 certified. Rigorous testing including salt spray, thermal cycling, and pull-force validation.

Professional Installation Guide

Follow these steps for optimal performance and longevity of your heat shrink terminals

1.Prepare the Wire

Strip 6-10mm of insulation using wire strippers. Twist stranded wires tightly for secure connection.

2.Insert Wire

Slide terminal onto wire until conductor touches metal barrel. Ensure no bare wire is visible outside terminal.

3.Crimp Connection

Use proper crimping tool matching terminal size. Crimp metal barrel firmly without over-crimping to avoid wire damage.

4.Apply Heat

Use heat gun at 100-120°C. Start from middle and move evenly toward ends. Watch for adhesive melt indicating proper seal.

5.Inspect Quality

Strip 6-10mm of insulation using wire strippers. Twist stranded wires tightly for secure connection.

In extremely wet environments, consider adding a small amount of dielectric grease For maximum wire insertion, pre-twist conductors with lineman's pliers In high-vibration applications, secure wires with additional cable ties For underground applications, wrap the connection with self-fusing silicone tape for enhanced protection

Get Your Free Sample!

We provide samples for free, you just need to tell us what you need

More Than Just a Waterproof Wire Nut Manufacturer

At Tonful Electric, we don’t just manufacture products—we engineer solutions for real-world challenges.

Service Consultation

Whether your heat shrink terminal requirements are straightforward or complex, our team provides expert advice and technical consultation. For more intricate projects, we offer in-depth engineering support to ensure optimal product selection and application, guaranteeing safety and efficiency in your electrical systems.

Product Recommendations

Unsure which heat shrink terminal suits your system? Our specialists provide free, customized recommendations based on your specific operational and environmental requirements, ensuring you get the perfect fit for your electrical protection needs.

Installation Support

Need help with installation? Our technical team is available to answer your questions or provide hands-on support. For larger projects, we can even dispatch an engineer to your site for on-the-ground assistance, ensuring your RCCBs are installed correctly and function seamlessly within your electrical network.

Logistics Support

If you lack a reliable freight forwarder, we can arrange transportation from our factory to your project site at no extra cost. Our logistics team ensures timely and secure delivery to keep your project on schedule, minimizing downtime and delays.

Frequently Asked Questions

We have compiled some common questions from our clients. If your question isn’t included here, our customer service is always available to help. We’d love to talk with you.

1. What is a heat shrink terminal?

A heat shrink terminal is an insulated electrical connector that, when heated, shrinks tightly around a wire connection to provide a secure, waterproof, and corrosion-resistant seal. It combines a metal crimp terminal with a heat-activated insulating sleeve.

2. How does a heat shrink terminal work?

Step 1: Strip the wire and crimp the metal part of the terminal.

Step 2: Apply heat (using a heat gun or torch), causing the outer sleeve to shrink.

Step 3: The inner adhesive (if dual-wall) melts, creating a waterproof seal.

3. What’s the difference between single-wall and dual-wall heat shrink terminals?

Type Features Best For

Single-Wall Basic insulation, no adhesive Indoor, dry environments

Dual-Wall Inner adhesive for waterproofing Outdoor, marine, automotive

4. Can I use a lighter instead of a heat gun?

Yes, but with caution! A lighter can work for quick fixes, but it may:

Overheat and damage the terminal.

Create uneven shrinking.

Recommended: Use a low-temperature heat gun (~120°C) for best results.

5. What wire sizes do heat shrink terminals support?

TONFUL’s terminals typically fit 0.5mm² to 16mm² wires (AWG 24–6). Always check the product specs before use.

6. Are heat shrink terminals reusable?

No! Once shrunk, they cannot be reopened without damage. Cut and replace if rework is needed.

7. How do I choose the right heat shrink terminal?

Consider:

✔ Wire gauge (must match terminal size).

✔ Environment (waterproof? high heat?).

✔ Current rating (check ampacity for high-power applications).

8. Can heat shrink terminals handle high temperatures?

Standard terminals: -40°C to +125°C.

High-temp versions (silicone/fluoropolymer): Up to 200°C+ (e.g., engine bays).

9. Do heat shrink terminals prevent corrosion?

Yes! The sealed design blocks moisture and chemicals, making them ideal for:

Marine applications.

Automotive wiring.

Industrial machinery.

10. Why choose TONFUL’s heat shrink terminals?

✅ UL & RoHS certified – Safe and reliable.

✅ Dual-wall options – Superior waterproofing.

✅ Custom sizes – OEM/ODM support available.

Request Information

Ready to elevate your electrical connections with industry-leading Heat Shrink Terminals?