Wire ferrule terminals are insulated or non-insulated metal sleeves crimped onto stranded wire ends to create a solid, reliable electrical connection that prevents wire fraying and ensures consistent contact with terminal blocks, switches, and other electrical components. These small but critical components dramatically improve connection reliability, reduce maintenance issues, and ensure code compliance in professional electrical installations.

Quick Answer: Ferrule terminals transform stranded wire ends into solid, professional connections that meet electrical codes, prevent wire strand damage, and provide superior contact reliability compared to bare stranded wire connections.

What Are Wire Ferrule Terminals?

Wire ferrule terminals are tubular metal sleeves, typically made from tin-plated copper, that are crimped onto the ends of stranded electrical wires. They serve as the interface between flexible stranded conductors and fixed terminal connections, essentially converting stranded wire ends into solid, pin-like connections.

Key Components:

- Metal sleeve: Usually tin-plated copper for corrosion resistance

- Insulation collar: Color-coded plastic sleeve (on insulated ferrules)

- Crimp area: Designed for specific wire gauges and crimping tools

Wire Ferrule vs. Bare Wire: Critical Differences

| Feature | Wire Ferrules | Bare Stranded Wire |

|---|---|---|

| Connection Reliability | Solid, consistent contact | Individual strands may break or shift |

| Code Compliance | Required by many electrical codes | Often prohibited in commercial applications |

| Wire Strand Protection | Complete protection from fraying | Strands can fray, break, or spread |

| Maintenance Requirements | Minimal – connections stay tight | Regular retightening needed |

| Professional Appearance | Clean, uniform connections | Can appear messy or unprofessional |

| Installation Time | Quick crimping process | Time-consuming wire preparation |

| Long-term Performance | Maintains integrity over years | Degrades with thermal cycling |

| Cost per Connection | $0.02-$0.15 per ferrule | No material cost |

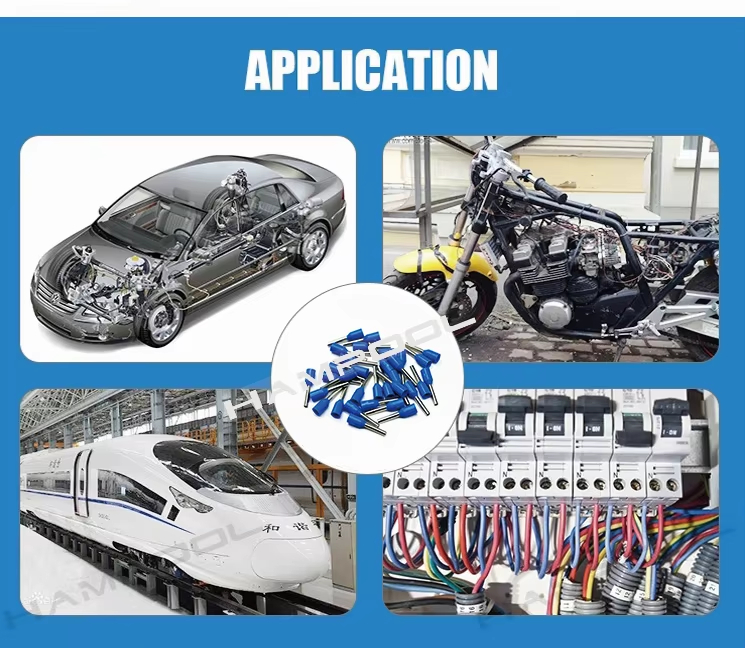

Primary Applications for Wire Ferrule Terminals

Industrial Control Systems

Wire ferrules are essential in industrial control panels where reliable connections prevent costly downtime. They provide consistent contact pressure and prevent loose connections that could cause arc faults or system failures.

Common Uses:

- PLC (Programmable Logic Controller) wiring

- Motor control centers

- Variable frequency drive connections

- Safety system wiring

HVAC Control Wiring

Heating, ventilation, and air conditioning systems rely on ferrule terminals for low-voltage control circuits that must maintain precise connections despite temperature fluctuations and vibration.

Applications Include:

- Thermostat wiring connections

- Zone control panels

- Actuator and damper controls

- Building automation systems

Electrical Panel Connections

Professional electrical panels use ferrules to ensure all stranded wire connections meet code requirements and maintain long-term reliability.

Panel Applications:

- Circuit breaker connections

- Neutral and ground bus bars

- Auxiliary contact wiring

- Metering and monitoring circuits

Telecommunications and Data Centers

Critical communications infrastructure demands the highest connection reliability, making ferrules standard practice for power and control wiring.

Specific Uses:

- UPS (Uninterruptible Power Supply) connections

- Power distribution units

- Emergency shutdown systems

- Cable tray and conduit connections

Wire Ferrule Types and Specifications

Insulated Ferrules

| Wire Gauge (AWG) | Ferrule Length | Insulation Color | Crimp Tool Required |

|---|---|---|---|

| 24 AWG | 6mm | White | Precision crimper |

| 22 AWG | 8mm | White | Precision crimper |

| 20 AWG | 8mm | Blue | Standard crimper |

| 18 AWG | 8mm | Blue | Standard crimper |

| 16 AWG | 10mm | Yellow | Standard crimper |

| 14 AWG | 12mm | Gray | Standard crimper |

| 12 AWG | 12mm | Red | Heavy-duty crimper |

| 10 AWG | 12mm | Red | Heavy-duty crimper |

Non-Insulated Ferrules

Best for applications where insulation would interfere with terminal design or where space is extremely limited.

Common Specifications:

- Material: Tin-plated copper

- Temperature rating: -40°F to 221°F (-40°C to 105°C)

- Voltage rating: 600V

- Available in all standard wire gauges

⚠️ SAFETY WARNING

Always use properly rated ferrules for your specific application. Undersized ferrules can create high resistance connections leading to overheating and fire hazards. Oversized ferrules may not crimp properly, resulting in loose connections.

How to Select the Right Wire Ferrule

Wire Gauge Compatibility

The ferrule must match the wire gauge exactly. Using an incorrect size compromises the connection and may violate electrical codes.

Selection Process:

- Identify wire gauge using a wire gauge tool

- Check manufacturer specifications for exact compatibility

- Verify crimp tool compatibility before purchasing

- Consider environmental factors (temperature, moisture, chemicals)

Environmental Considerations

| Environment | Ferrule Type | Special Requirements |

|---|---|---|

| Standard Indoor | Tin-plated copper | Standard insulation acceptable |

| High Temperature | Tin-plated copper | High-temp insulation required |

| Outdoor/Wet | Tin-plated copper | Sealed connections needed |

| Corrosive | Stainless steel | Chemical-resistant materials |

| High Vibration | Standard with locking terminals | Additional strain relief |

Step-by-Step Ferrule Installation Process

Required Tools

- Wire strippers (precision type recommended)

- Ferrule crimping tool (gauge-specific)

- Wire gauge measuring tool

- Safety glasses

Installation Steps

- Strip wire to exact length

- Remove insulation equal to ferrule length minus 1mm

- Ensure no nicks in conductor strands

- Insert wire into ferrule

- Push wire fully into ferrule until insulation touches collar

- Verify all strands are captured inside ferrule

- Position in crimping tool

- Select correct die size for ferrule

- Center ferrule in crimping jaws

- Execute crimp

- Apply firm, steady pressure until tool releases

- Inspect crimp for proper compression

- Quality check

- Verify ferrule is securely attached

- Check that no wire strands are visible outside ferrule

💡 EXPERT TIP

Always perform a gentle pull test after crimping. A properly crimped ferrule should not move or rotate on the wire when pulled with moderate force.

Code Compliance and Standards

National Electrical Code (NEC) Requirements

The NEC requires that stranded wire connections in many commercial and industrial applications use approved termination methods, including ferrules.

Key NEC References:

- Article 110.14: Electrical connections must be made with approved methods

- Article 430.9: Motor connections require reliable termination

- UL 486E: Standard for ferrule-type terminal lugs

International Standards

- IEC 60947-7-1: Low-voltage switchgear terminal blocks

- DIN 46228: German standard for wire-end ferrules

- VDE 0100: Installation standards requiring ferrules in specific applications

Troubleshooting Common Ferrule Issues

Poor Crimp Quality

Symptoms: Loose connection, ferrule rotates on wire

Solution: Use proper crimping tool with correct die size, ensure full compression

Wire Strand Damage

Symptoms: Broken strands visible outside ferrule

Solution: Use sharper wire strippers, avoid over-stripping, replace damaged wire section

Incorrect Ferrule Size

Symptoms: Loose fit or difficulty inserting wire

Solution: Verify wire gauge with proper measuring tool, select exact size ferrule

When to Use Professional Installation

While ferrule installation appears straightforward, certain applications require professional expertise:

Professional Installation Recommended:

- High-voltage applications (over 250V)

- Safety-critical systems

- Code-required installations

- Complex control panel wiring

- Applications requiring electrical inspection

Maintenance and Inspection Guidelines

Regular Inspection Schedule

- Monthly: Visual inspection for loose connections

- Annually: Thermal imaging to detect high-resistance connections

- During service: Check ferrule condition when performing maintenance

Signs of Ferrule Failure

- Discoloration around connection points

- Loose terminal screws despite proper torque

- Intermittent electrical faults

- Visible damage to ferrule or wire

Cost-Benefit Analysis: Ferrules vs. Alternatives

| Factor | Wire Ferrules | Spade Terminals | Ring Terminals | Bare Wire |

|---|---|---|---|---|

| Initial Cost | Low ($0.02-$0.15) | Medium ($0.10-$0.30) | Medium ($0.10-$0.30) | None |

| Installation Time | Fast (30 seconds) | Medium (1 minute) | Medium (1 minute) | Slow (2+ minutes) |

| Reliability | Excellent | Good | Excellent | Poor |

| Maintenance | Minimal | Low | Minimal | High |

| Code Compliance | Excellent | Good | Good | Often inadequate |

| Professional Appearance | Excellent | Good | Good | Poor |

Frequently Asked Questions

What makes wire ferrules better than bare stranded wire?

Wire ferrules prevent individual wire strands from breaking, fraying, or creating loose connections. They provide consistent contact pressure and meet electrical code requirements for professional installations.

Do I need insulated or non-insulated ferrules?

Use insulated ferrules when adjacent terminals could create short circuits or when color-coding helps with wire identification. Non-insulated ferrules work well in single-wire applications with adequate spacing.

Can I reuse a ferrule if I need to relocate a wire?

No. Ferrules are designed for single-use applications. Once crimped, they should not be removed and reused as this compromises the connection integrity.

What crimp tool should I use for ferrules?

Use a tool specifically designed for ferrules with the correct die size for your wire gauge. Pliers or generic crimpers do not provide the proper compression pattern needed for reliable connections.

Are ferrules required by electrical code?

Many commercial and industrial applications require ferrules or approved wire termination methods. Check local electrical codes and NEC requirements for your specific application.

How do I know if my ferrule crimp is good quality?

A proper crimp should show the ferrule compressed evenly around the wire with no gaps. The wire should not pull out with moderate force, and the ferrule should not rotate on the wire.

What’s the difference between European and American ferrule standards?

European ferrules often use metric sizing and may have different color coding. American ferrules typically follow AWG sizing and have standardized color codes for easy identification.

Can ferrules be used with solid wire?

Ferrules are specifically designed for stranded wire applications. Solid wire should be terminated directly into appropriate terminals without ferrules.

Quick Reference: Ferrule Selection Guide

For Control Panel Wiring: Use insulated ferrules with color coding

For High-Temperature Applications: Specify high-temp insulation materials

For Outdoor Applications: Ensure proper environmental sealing

For Critical Systems: Always perform pull tests and thermal inspections

For Code Compliance: Verify local requirements and use approved products

Professional Recommendation: Always consult with a qualified electrician for applications involving safety systems, high voltage, or when electrical code compliance is uncertain. Proper ferrule installation significantly improves electrical system reliability and safety when performed according to manufacturer specifications and electrical codes.