Wire terminals are electrical connectors that create secure, reliable connections between wires and electrical components, ensuring proper current flow and preventing dangerous loose connections that can cause fires, equipment damage, or electrical shock.

Key Takeaway: Proper wire terminal selection and installation is critical for electrical safety, code compliance, and system reliability in residential, commercial, and industrial applications.

What Are Wire Terminals? Essential Definitions

Wire terminals are specialized electrical connectors designed to terminate wire ends and create secure mechanical and electrical connections to components, panels, or other wires. These connectors eliminate the safety risks and code violations associated with twisted wire connections or inadequate terminations.

Primary Functions:

- Create secure mechanical connections that resist vibration and thermal cycling

- Establish low-resistance electrical pathways for reliable current flow

- Provide code-compliant terminations that meet NEC and local electrical standards

- Enable easy disconnection for maintenance and troubleshooting

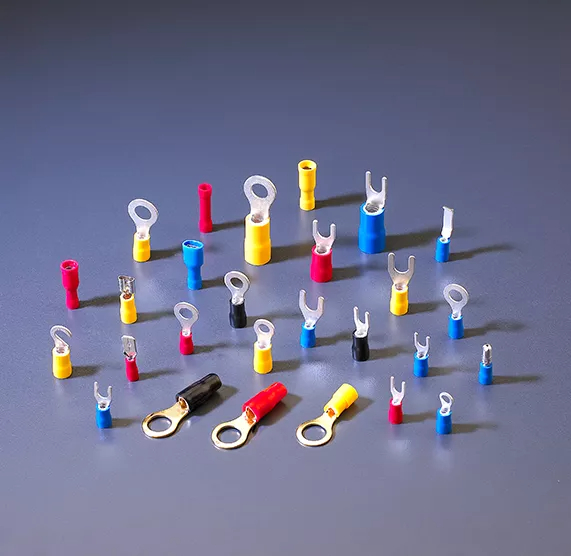

Wire Terminal Types: Comprehensive Comparison

Here is a table that shows the main wire terminal types and their specific applications:

| Terminal Type | Wire Range (AWG) | Installation Method | Primary Applications | Voltage Rating | Environmental Rating |

|---|---|---|---|---|---|

| Ring Terminals | 22-4/0 | Crimped | Panel connections, grounding | 600V-35kV | Indoor/Outdoor |

| Spade Terminals | 22-10 | Crimped | Quick-disconnect applications | 250V-600V | Indoor primarily |

| Butt Splice | 22-4/0 | Crimped | Wire-to-wire connections | 600V-35kV | Indoor/Outdoor |

| Wire Nuts | 18-6 | Twisted/threaded | Residential branch circuits | 600V max | Indoor only |

| Lever Nuts | 24-12 | Push-in/lever | Modern residential/commercial | 600V | Indoor/Outdoor rated |

| Terminal Blocks | 30-4/0 | Screw/spring clamp | Control panels, distribution | 1000V+ | Various ratings |

| Heat Shrink Terminals | 22-4/0 | Crimped + heated | Marine, automotive, outdoor | 600V-35kV | Waterproof sealed |

Critical Applications and Use Cases

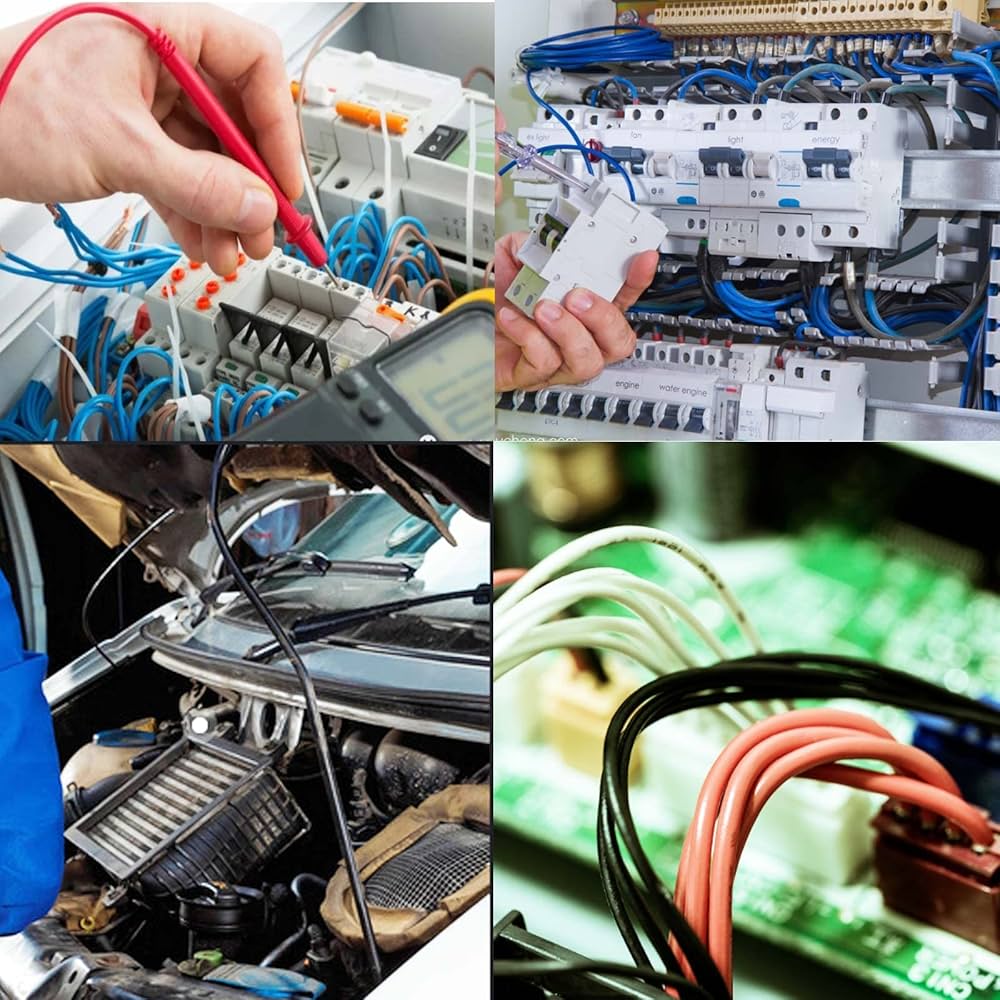

Residential Electrical Systems

Branch Circuit Connections:

Wire nuts and lever nuts dominate residential applications for connecting fixture wires, switch legs, and branch circuit splices. Modern lever nuts (WAGO-style) provide superior connection reliability compared to traditional wire nuts, especially in high-vibration environments.

Panel and Grounding Applications:

Ring terminals are mandatory for main panel grounding connections, equipment grounding conductors, and bonding jumpers. The NEC specifically requires listed pressure connectors for grounding electrode conductor terminations.

Commercial and Industrial Applications

Control Panel Wiring:

Terminal blocks enable organized, maintainable connections in motor control centers, VFD panels, and automation systems. Spring-clamp terminals reduce installation time while providing gas-tight connections that resist corrosion.

High-Current Applications:

Large ring terminals (1/0 AWG and larger) with proper torque specifications ensure reliable connections in main service equipment, transformers, and industrial machinery connections.

Wire Terminal Selection Criteria: Expert Decision Framework

Current-Carrying Capacity Requirements

Ampacity Considerations:

Terminal ampacity must meet or exceed the circuit’s maximum current requirements. Undersized terminals create resistance heating that can cause fire hazards and code violations.

Temperature Rating Compatibility:

Terminal temperature ratings must match or exceed the connected wire’s insulation rating (60°C, 75°C, or 90°C) to prevent insulation degradation and maintain code compliance.

Environmental and Application Factors

Moisture and Chemical Exposure:

- Indoor dry locations: Standard uncoated terminals acceptable

- Damp/wet locations: Heat shrink or sealed terminals required by NEC 110.14(B)

- Corrosive environments: Tin-plated or stainless steel terminals prevent galvanic corrosion

Vibration and Mechanical Stress:

Applications with significant vibration (motor connections, automotive) require crimped connections rather than screw terminals to prevent loosening over time.

Installation Best Practices and Safety Requirements

Professional Crimping Techniques

Step-by-Step Crimping Process:

- Strip wire to manufacturer specifications – Typically 3/8″ for most terminals

- Select proper die and terminal size – Match AWG rating exactly

- Insert wire fully into terminal barrel – Conductor should extend slightly beyond barrel

- Position crimping tool squarely – Ensure even pressure distribution

- Apply full compression in single stroke – Partial crimps create high resistance

- Inspect crimp quality – Look for proper barrel deformation and conductor retention

🔧 Expert Tip: Use a crimping tool with compound leverage and proper die sets. Harbor freight tools lack the precision for code-compliant connections. Invest in professional-grade tools like Klein, Greenlee, or Burndy crimpers.

Code Compliance and Safety Standards

NEC Requirements for Terminal Connections:

- Article 110.14(A): All splice and termination connections must use listed devices

- Article 250.8: Grounding connections require listed pressure connectors

- Article 314.17: Wire splices must be accessible and properly enclosed

⚠️ Safety Warning: Never use electrical tape alone for wire connections. Tape is only acceptable as additional protection over proper mechanical connectors. Twisted wire connections without proper terminals violate electrical codes and create fire hazards.

Common Problems and Professional Solutions

Connection Failure Modes

High-Resistance Connections:

Symptoms include heating at connection points, voltage drops, and eventual failure. Causes include inadequate crimping, corrosion, or undersized terminals.

Solution: Use proper crimping tools with calibrated dies, apply di-electric grease in outdoor applications, and follow torque specifications for screw terminals.

Corrosion and Degradation:

Dissimilar metals (aluminum wire with copper terminals) create galvanic corrosion that increases resistance and creates fire hazards.

Solution: Use terminals specifically rated for aluminum conductors (marked “AL” or “CU/AL”) and apply antioxidant compound per manufacturer specifications.

Advanced Terminal Applications

Specialized Industrial Connections

High-Voltage Applications (Over 600V):

Require specialized terminals with enhanced insulation, corona protection, and specific installation procedures. These connections mandate professional installation by licensed electricians with high-voltage training.

Explosion-Proof and Hazardous Locations:

Class I, Division 1 locations require terminals and enclosures specifically listed for hazardous environments. Standard terminals create ignition risks in explosive atmospheres.

Selection Guide: Choosing the Right Terminal

Quick Decision Matrix

For Residential Applications:

- Wire nuts: Traditional choice for permanent splices in junction boxes

- Lever nuts: Superior choice for connections requiring frequent access

- Ring terminals: Required for all grounding and panel connections

For Commercial/Industrial:

- Terminal blocks: Organized control panel wiring

- Heat shrink terminals: Outdoor or high-vibration applications

- Compression terminals: High-current and utility connections

Professional Recommendations

Quality Standards to Specify:

- UL listing for intended application (UL 486A for splicing, UL 486B for grounding)

- Temperature rating matching conductor insulation

- Proper AWG range for intended wire sizes

- Environmental ratings appropriate for installation location

Frequently Asked Questions

What’s the difference between crimped and screw terminals?

Crimped terminals create gas-tight connections through mechanical deformation that excludes oxygen and prevents corrosion. Screw terminals rely on pressure and can loosen over time, especially in vibration-prone applications.

Can I use automotive terminals for household electrical work?

No. Automotive terminals are designed for 12V DC systems and lack the insulation ratings required for 120V/240V AC household circuits. Always use UL-listed terminals rated for your specific voltage and application.

How do I know if my crimp connection is properly made?

A proper crimp should capture both the conductor and insulation, show even barrel deformation without cracks, and require significant force to pull apart. The conductor should not pull out of the terminal under moderate hand pressure.

What size terminal do I need for my wire gauge?

Terminal sizing must exactly match your wire AWG. Using oversized terminals creates poor connections, while undersized terminals won’t accept the conductor properly. Check the terminal manufacturer’s specifications for exact AWG compatibility.

Are wire nuts still code compliant?

Yes, properly installed wire nuts remain NEC compliant for appropriate applications. However, many professionals prefer lever nuts for their superior connection reliability and easier installation verification.

When do I need heat shrink terminals instead of regular ones?

Use heat shrink terminals in outdoor applications, marine environments, underground installations, or anywhere moisture intrusion could cause corrosion. The sealed barrier prevents water entry that degrades standard crimp connections.

Safety Considerations and Code Compliance

Critical Safety Requirements

Professional Installation Recommendations:

Complex electrical connections, high-voltage applications, and main service equipment require installation by licensed electricians. DIY electrical work may violate local codes and insurance requirements.

Inspection and Testing:

All terminal connections should undergo proper inspection including visual examination for proper engagement, thermal imaging for hot spots, and torque verification for screw-type connections.

National Electrical Code Compliance

Key NEC Articles for Terminal Applications:

- 110.14: General connection requirements and temperature limitations

- 250.8: Equipment grounding conductor connections

- 314.16: Junction box wire limitations and accessibility

- 408.3: Switchboard and panelboard connection requirements

Conclusion: Professional Terminal Selection and Installation

Wire terminals form the critical foundation of electrical system safety and reliability. Proper selection based on current requirements, environmental conditions, and code compliance ensures decades of safe operation while preventing the fire hazards and equipment damage associated with poor connections.

Professional Recommendation: For any electrical work beyond basic residential applications, consult with licensed electricians who understand local code requirements and have access to professional-grade tools and materials. The cost of proper installation far outweighs the risks of inadequate connections.

Next Steps: Evaluate your specific application requirements, verify local code compliance needs, and invest in quality terminals and proper installation tools for lasting electrical safety and reliability.