In the world of electrical engineering and automotive circuit protection, few concepts are as critical—and potentially devastating—as thermal runaway. While often associated with battery failures, thermal runaway in fused circuits is a direct consequence of improper overcurrent protection. As a leading blade fuses manufacturer, TONFUL Electric understands that the humble fuse is the primary line of defense against catastrophic electrical fires.

Thermal runaway occurs when an increase in temperature changes the conditions in a way that causes a further increase in temperature, leading to a destructive positive feedback loop. In the context of circuit protection, this typically happens when a fuse fails to interrupt excessive current before the wire insulation degrades. Using the wrong amp fuse isn’t just a minor maintenance error; it is a critical safety violation that bypasses the carefully calculated thermal limits of an electrical system.

What is Thermal Runaway in Electrical Systems?

Technically defined, thermal runaway in wiring assemblies is an uncontrolled temperature rise caused by resistive heating (Joule heating) that exceeds the dissipation capacity of the system. The fundamental physics equation governing this is P = I2R, where Power (heat) equals Current squared times Resistance.

When an electrical circuit carries current, it naturally generates heat. In a properly designed system, this heat dissipates safely into the surrounding environment. However, if the current (I) exceeds the wire’s rated capacity—and the automotive fuse does not blow to stop it—the heat generation increases exponentially.

This excess heat degrades the wire’s insulation and increases the resistance of copper conductors (as copper has a positive temperature coefficient). Higher resistance leads to even more heat generation for a given voltage drop, creating a self-reinforcing cycle. Eventually, the insulation melts or carbonizes, leading to short circuits, arcing, and potentially an electrical fire. This is why understanding what is the purpose of a blade fuse is essential: it serves as the intentional “weak link” that must fail before thermal runaway can begin.

Understanding Fuse Ratings and Wire Gauge Compatibility

The safety of any electrical circuit relies on the strict relationship between the wire gauge (AWG), the insulation type, and the fuse rating. Ampacity refers to the maximum amount of current a conductor can carry continuously without exceeding its temperature rating. The fuse must always be rated lower than the wire’s ampacity.

Automotive systems use a standardized color-coding system to identify ratings quickly. For detailed identification, engineers refer to our automotive blade fuse amp ratings and color codes guide. A mismatch here is dangerous. For example, replacing a 10A fuse (Red) with a 20A fuse (Yellow) in a circuit designed for 10A allows double the current to flow through wires not sized to handle it.

Below is a general compatibility chart for standard automotive wire (Stranded Copper, typically rated for 125°C in engine bays).

Table 1: Wire Gauge to Maximum Fuse Rating Chart

| Wire Gauge (AWG) | Typical Ampacity (Continuous) | Maximum Safe Fuse Rating | Common Fuse Color (ATO/Mini) |

|---|---|---|---|

| 20 AWG | 5-7 Amps | 5A | Tan |

| 18 AWG | 7-10 Amps | 7.5A or 10A | Brown / Red |

| 16 AWG | 10-13 Amps | 10A or 15A | Red / Blue |

| 14 AWG | 15-20 Amps | 20A | Yellow |

| 12 AWG | 20-25 Amps | 25A or 30A | Clear / Green |

| 10 AWG | 30-40 Amps | 30A or 40A | Green / Orange |

Note: Always consult specific manufacturer data and SAE standards, as wire length and bundling affect these values.

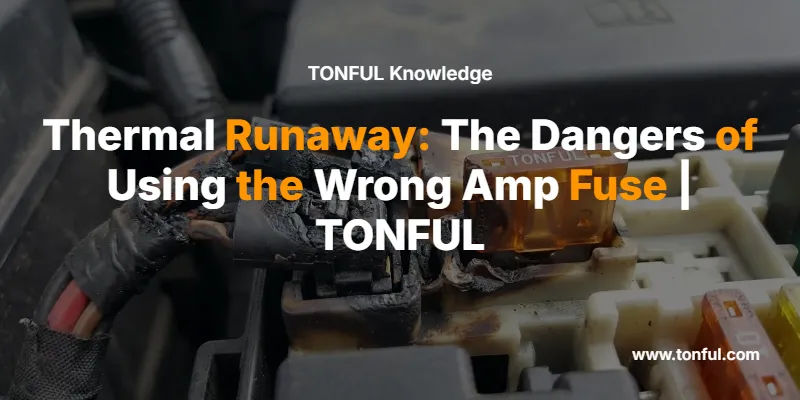

The Catastrophic Consequences of Using Wrong Amp Fuses

The practice of “over-fusing”—installing a fuse with a higher amperage rating than specified—is the leading cause of wiring harness failures. It typically happens when a user experiences a blown fuse and, lacking the correct replacement, installs a larger one believing it is an “upgrade” or a temporary fix.

The consequences are severe:

- Delayed Protection: An oversized fuse will not blow during a moderate overload. If a short circuit occurs, it allows significantly higher energy let-through (I2t) before clearing the fault.

- Wire Overheating: The wire becomes the fuse. Instead of the sacrificial element inside the fuse melting safely, the copper wire along the length of the vehicle chassis heats up.

- Fire Risk: According to the National Fire Protection Association (NFPA), approximately 20% of electrical fires are caused by improper distribution of electrical components, including incorrect fusing.

Conversely, using an undersized fuse leads to “nuisance tripping.” While less dangerous thermally, it causes system downtime and can lead users to bypass the fuse entirely—a worst-case scenario. Learning when to replace a blown blade fuse and choosing the right rating is vital for fleet maintenance and longevity.

How Thermal Runaway Develops in Fused Circuits

Thermal runaway in a circuit with an incorrect fuse rating follows a predictable but rapid timeline. It begins when the load current exceeds the wire’s rating but remains below the wrong fuse’s blow point.

Table 2: Thermal Runaway Temperature Progression

| Stage | Temperature Range | Physical Effect on Components | Fuse Status (Incorrect Rating) |

|---|---|---|---|

| 1. Overload | 40°C – 80°C | Wire becomes warm to touch; increased resistance. | Intact: Current is below fuse threshold. |

| 2. Insulation Stress | 100°C – 150°C | PVC insulation softens; “hot plastic” smell emits. | Intact: Still conducting current. |

| 3. Insulation Failure | 200°C – 300°C | Insulation melts/drips; conductors exposed. | Intact: Fuse has not reached melting point (I2t). |

| 4. Thermal Runaway | >300°C | Smoke generation; copper oxidation; potential ignition of surrounding materials. | Intact or Late Blow: Damage is already done. |

| 5. Short Circuit | Arc Temp (>1000°C) | Exposed wires touch chassis/ground; massive current spike. | Finally Blows: Often too late to prevent fire. |

Industry Standards and Safety Requirements

To prevent thermal runaway, fuses must meet rigorous international standards. As a reputable auto fuse manufacturer, TONFUL adheres to standards set by UL (Underwriters Laboratories), IEC (International Electrotechnical Commission), and SAE (Society of Automotive Engineers).

Key standards include:

- ISO 8820 / SAE J1284: Defines performance for automotive blade fuses.

- UL 248: Standard for low-voltage fuses.

These standards mandate that a fuse must open within a specific time frame at defined overload percentages (e.g., 135% of rated current). Cheap, non-compliant fuses often fail to open within these windows, exacerbating thermal risks. When procuring components, it is essential to source auto fuse suppliers who can provide verifiable compliance data.

Best Practices for Fuse Selection

Selecting the correct fuse involves more than just guessing. It requires calculation and consideration of the specific fuse type—whether you need Standard vs. Mini blade fuses or high-current Maxi blade fuses.

The 125% Rule: For continuous loads, the fuse rating should typically be 125% of the device’s continuous current draw, provided the wire ampacity is higher than the fuse rating.

Table 3: Automotive Blade Fuse Types Comparison

| Fuse Type | Dimensions (mm) | Current Range | Primary Application |

|---|---|---|---|

| Micro2 / Micro3 | Smallest footprint | 5A – 30A | High-density modern fuse boxes. |

| Mini (ATM/APM) | 10.9 x 3.6 x 16.3 | 2A – 30A | General circuit protection (lighting, radio). |

| Standard (ATO/ATC) | 19.1 x 5.1 x 18.5 | 1A – 40A | Most common automotive & marine circuits. |

| Maxi (APX) | 29.2 x 8.5 x 34.3 | 20A – 120A | High current loads (starters, AC fans). |

Table 4: Correct vs. Incorrect Fuse Selection Checklist

| Factor | Correct Selection Strategy | Dangerous Mistake |

|---|---|---|

| Amp Rating | Matches or is slightly lower than wire ampacity. | Exceeds wire ampacity (“It kept blowing, so I put a bigger one”). |

| Voltage Rating | Fuse voltage ≥ Circuit voltage (e.g., using ATO 80V fuses). | Using 12V fuses in 48V EV systems (arcing risk). |

| Type/Size | Exact physical match (e.g., Mini vs Micro vs Standard). | Jamming wrong size into holder; poor contact causes heat. |

| Environment | Using waterproof blade fuses for marine/off-road. | Using standard open fuses in wet areas (corrosion resistance). |

Always verify your selection by testing the blade fuse with a multimeter to ensure continuity and proper resistance before installation.

FAQ Section

1. What happens if I use a higher amp fuse than recommended?

Using a higher amp fuse prevents the circuit from breaking during an overload. This forces the electrical wiring to carry more current than it was designed for, leading to overheating, melted insulation, and a high risk of electrical fire (thermal runaway).

2. Can thermal runaway occur even with the correct fuse installed?

Yes, but it is less likely. It can occur if there is a loose connection (high resistance) at the fuse holder or terminal. This generates localized heat that the fuse may not detect since the current flow hasn’t increased, only the resistance heat. Proper crimp quality is essential here.

3. How do I calculate the correct fuse rating for my circuit?

First, determine the maximum current draw of your device (Amps = Watts / Volts). Second, verify your wire gauge ampacity is higher than this draw. Select a fuse rating that is about 125% of the load current but never higher than the wire’s ampacity rating.

4. What are the warning signs of an incorrectly rated fuse?

Signs include wires that are hot to the touch, a smell of burning plastic, discolored or melted fuse blocks, and flickering lights. If a fuse does not blow when a known short occurs, it is dangerously oversized.

5. Are automotive blade fuses interchangeable between different amp ratings?

Physically, yes—and this is the danger. An ATO 30A fuse fits in the same slot as an ATO 5A fuse. However, they are electrically not interchangeable. You must strictly adhere to the amp rating specified on the fuse box cover or owner’s manual.

6. What is the difference between glass fuses and blade fuses regarding thermal safety?

While both protect against overcurrent, blade fuses generally offer better vibration resistance and contact surface area for automotive applications. For a detailed breakdown, read our blade fuse vs glass fuse comparison guide.