Yes, waterproof and water-resistant blade fuses specifically designed for marine and off-road applications are widely available. These specialized fuses feature sealed housings, corrosion-resistant materials, and protective coatings that prevent water intrusion, salt corrosion, and environmental damage in harsh conditions where standard automotive fuses would fail.

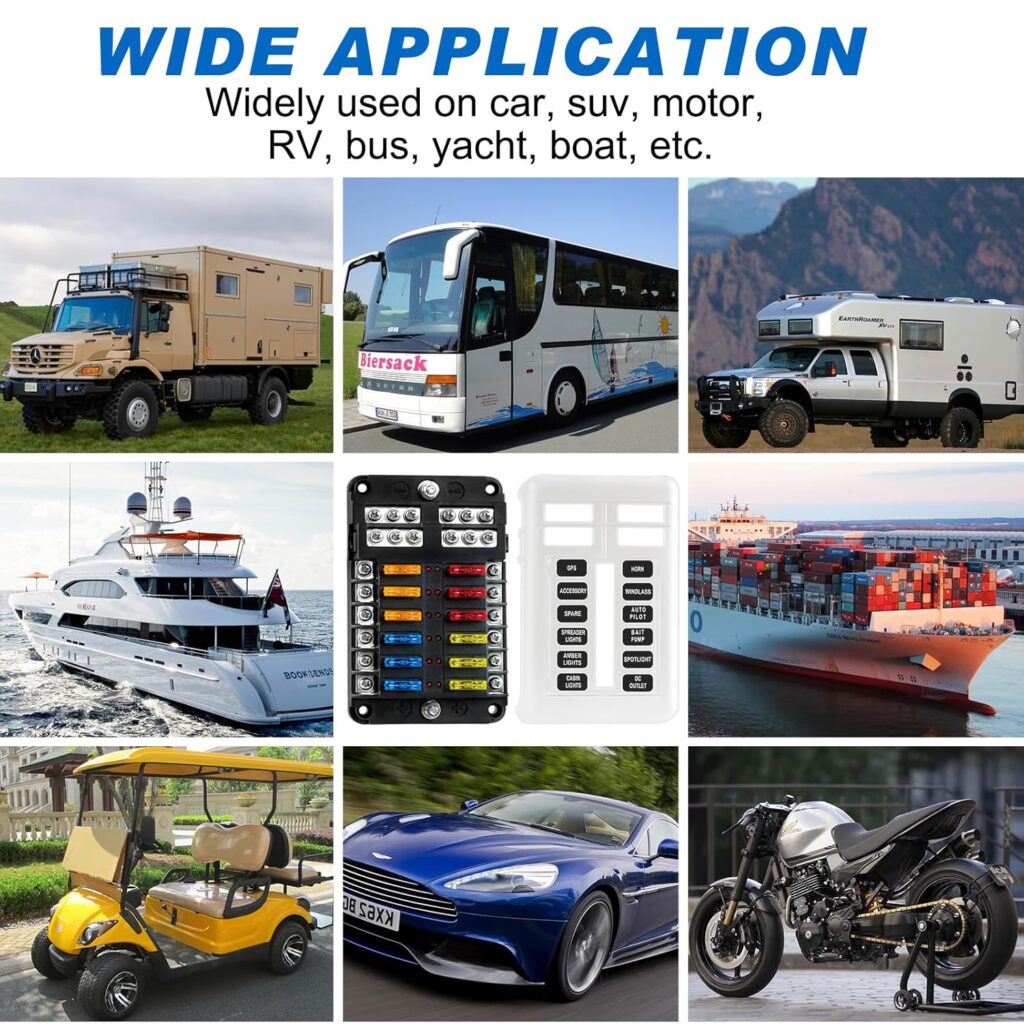

Understanding waterproof blade fuses is essential if you’re protecting electrical systems in boats, ATVs, UTVs, RVs, or any vehicle exposed to moisture, spray, or submersion. This guide provides everything you need to select, install, and maintain water-resistant fuses that keep your circuits protected in the most demanding environments.

What Are Waterproof Blade Fuses?

Waterproof blade fuses are circuit protection devices designed with sealed construction and corrosion-resistant materials to function reliably in wet, humid, or corrosive environments. Unlike standard automotive blade fuses, these specialized fuses incorporate:

- Sealed housings that prevent water from reaching internal components

- Corrosion-resistant terminals made from tin-plated copper or marine-grade materials

- Protective coatings that resist salt spray, moisture, and chemical exposure

- Environmental ratings meeting marine industry standards (typically IP67 or higher)

These fuses maintain the same basic blade fuse design for compatibility with standard fuse blocks while adding protection layers that standard fuses lack.

Key Differences: Standard vs. Waterproof Blade Fuses

Here is a table that shows the critical differences between standard automotive and waterproof blade fuses:

| Feature | Standard Blade Fuses | Waterproof Blade Fuses |

|---|---|---|

| Housing | Open plastic body | Fully sealed enclosure |

| Terminal Material | Zinc or brass | Tin-plated copper or nickel-plated brass |

| Corrosion Resistance | Minimal (dry environments only) | High (salt spray and moisture rated) |

| IP Rating | None (IP00) | IP67 to IP68 (submersion rated) |

| Typical Environment | Dry automotive interiors | Marine, off-road, outdoor applications |

| Price Range | $0.25-$0.75 per fuse | $2.00-$8.00 per fuse |

| Lifespan in Wet Conditions | Weeks to months before failure | Years with proper installation |

| Standards Compliance | SAE J1284 | SAE J1284 + ABYC E-11 (marine) |

What makes waterproof blade fuses different from standard fuses? The sealed construction prevents moisture from causing corrosion on the fuse element and terminals, which is the primary failure mode for standard fuses in wet environments. This protection extends circuit reliability and prevents dangerous failures in critical systems.

Types of Waterproof Blade Fuses for Marine and Off-Road Use

1. Marine-Rated Blade Fuses

Purpose: Specifically engineered for saltwater environments on boats and watercraft.

Key Features:

- ABYC E-11 compliant for marine electrical systems

- Salt spray tested to ASTM B117 standards

- Tin-plated terminals resist galvanic corrosion

- IP67 or IP68 ratings for temporary submersion

- UV-resistant housings for above-deck installations

Best Applications: Bilge pumps, navigation lights, fish finders, marine electronics, trolling motors

2. Automotive Off-Road Fuses

Purpose: Designed for vehicles exposed to mud, water crossings, and extreme weather.

Key Features:

- Sealed against water, dust, and debris (IP67 rated)

- Vibration-resistant construction

- Temperature range: -40°F to 185°F (-40°C to 85°C)

- Compatible with standard ATO/ATC fuse holders

Best Applications: ATVs, UTVs, Jeeps, rock crawlers, agricultural equipment, snowmobiles

3. Heavy-Duty Sealed Fuses

Purpose: Industrial-grade protection for critical circuits in extreme conditions.

Key Features:

- IP68 rating (continuous submersion up to 3 feet)

- Higher current ratings (up to 100 amps)

- Military-spec materials and construction

- Extended temperature range performance

Best Applications: Construction equipment, mining vehicles, emergency response vehicles, military applications

Comparison Table: Top Waterproof Blade Fuse Options

| Fuse Type | IP Rating | Max Current | Price Range | Best For | Certification |

|---|---|---|---|---|---|

| Blue Sea Systems SafeFuse | IP67 | 2-30A | $4-6 | Marine electronics | ABYC E-11 |

| Bussman ATM Mini | IP67 | 5-30A | $2-4 | Compact installations | SAE J1284 |

| Littelfuse ATO Marine | IP67 | 3-40A | $3-5 | General marine use | UL Recognized |

| Cole Hersee Blade Fuse | IP68 | 5-50A | $5-8 | Heavy-duty off-road | SAE/ISO certified |

| Fastronix Solutions Sealed | IP67 | 5-40A | $3-5 | Off-road vehicles | SAE compliant |

How to Choose the Right Waterproof Blade Fuse

Step 1: Determine Your Environment Severity

You need to match the fuse’s protection level to your exposure conditions:

- Light exposure (occasional spray, humidity): IP65-rated fuses sufficient

- Moderate exposure (frequent spray, rain, splashing): IP67-rated fuses recommended

- Severe exposure (submersion, constant saltwater): IP68-rated marine fuses required

Step 2: Calculate Your Circuit Requirements

Match fuse amperage to your circuit protection needs:

- Calculate total circuit load (watts ÷ voltage = amps)

- Add 25% safety margin for startup surges

- Select next standard fuse rating above calculated value

- Never exceed wire gauge ampacity limits

Step 3: Check Compliance Requirements

Verify your application requires specific certifications:

- Marine vessels: ABYC E-11 compliance mandatory for Coast Guard requirements

- Off-road vehicles: SAE J1284 standard for automotive fuses

- Commercial applications: UL or CSA listing may be required

Step 4: Consider Fuse Holder Compatibility

Ensure your waterproof fuses work with your fuse panel:

- Standard ATO/ATC fuses fit most automotive-style holders

- Mini (ATM) fuses require compatible compact holders

- Maxi fuses for high-current applications (40-100 amps)

Expert Selection Tips

💡 Expert Tip: Always pair waterproof fuses with waterproof fuse holders. A waterproof fuse in a standard holder provides minimal protection since water enters through the holder connections.

💡 Expert Tip: For marine applications below the waterline, choose fuses with tin-plated rather than nickel-plated terminals. Tin provides superior corrosion resistance in saltwater environments.

Installation Best Practices for Maximum Protection

Step-by-Step Installation Process

Step 1: Prepare the Installation Area

- Clean all connection points with electrical contact cleaner

- Remove any existing corrosion with a wire brush

- Ensure mounting surface is dry before installation

- Apply dielectric grease to terminals before insertion

Step 2: Select Proper Fuse Holder

You must use waterproof fuse holders with waterproof fuses:

- Choose IP67-rated or higher fuse holders

- Verify holder seals are intact and undamaged

- Use marine-grade fuse blocks for boat installations

- Ensure holder ampacity matches or exceeds fuse rating

Step 3: Make Secure Connections

- Strip wire insulation to manufacturer specifications (typically 1/4 inch)

- Apply heat-shrink marine-grade terminals

- Use heat gun to properly seal terminals

- Apply dielectric grease to all connection points

- Insert fuse firmly until fully seated

Step 4: Seal and Protect

- Apply additional marine sealant around fuse holder mounting

- Route wiring away from direct water spray paths

- Secure connections with marine-grade zip ties

- Label all circuits clearly with waterproof labels

⚠️ SAFETY WARNING: Always disconnect battery power before installing or replacing fuses. Working on live circuits can cause electric shock, burns, or damage to electrical components.

⚠️ SAFETY WARNING: Never use a higher amperage fuse than specified for your circuit. Oversized fuses can allow dangerous overcurrent conditions that may cause fires or equipment damage.

Critical Installation Mistakes to Avoid

Common Error #1: Using standard fuse holders with waterproof fuses

- Result: Water enters through unsealed holder, causing corrosion

- Solution: Invest in matching waterproof fuse holders ($15-50 each)

Common Error #2: Improper terminal preparation

- Result: Poor electrical contact leads to heat buildup and failure

- Solution: Use marine-grade heat-shrink terminals with adhesive lining

Common Error #3: Inadequate wire routing

- Result: Direct water exposure overwhelms even waterproof protection

- Solution: Route wiring through protected channels; use drip loops at low points

Applications and Real-World Use Cases

Marine Applications

Bilge Pump Circuits

- Critical safety system requiring 100% reliability

- Constant exposure to water and humidity

- Recommended: IP68 marine-rated fuses, 10-15A typical

- Must meet ABYC E-11 standards for insurance compliance

Navigation and Electronics

- GPS, fish finders, radios, and chartplotters

- Deck-mounted equipment exposed to spray and rain

- Recommended: IP67 fuses with UV-resistant housings

- Proper protection prevents costly electronics failures

Off-Road Vehicle Applications

Winch and Accessory Lighting

- High-current draws during operation (40-80 amps)

- Exposure during water crossings and mudding

- Recommended: Maxi-fuse waterproof options or circuit breakers

- Vibration-resistant mounting essential

Engine Management and Sensors

- Critical circuits controlling fuel injection and ignition

- Under-hood environment with heat, moisture, and contaminants

- Recommended: IP67 ATO fuses with high-temp ratings

- Failure can strand vehicle in remote locations

RV and Trailer Applications

Exterior Lighting Circuits

- Marker lights, brake lights, backup lights

- Year-round weather exposure

- Recommended: IP67 ATM mini fuses for space-constrained locations

- Prevents roadside failures and citation issues

Troubleshooting Common Waterproof Fuse Problems

Problem: Fuse Keeps Blowing

Possible Causes:

- Actual circuit overload (correct fuse operation)

- Loose connections causing resistance and heat

- Moisture infiltration despite waterproof design

- Incorrect fuse rating for circuit load

Solutions:

- Verify circuit load calculation is correct

- Inspect all connections for tightness and corrosion

- Check fuse holder seals for damage

- Measure actual current draw with multimeter

Problem: Corrosion on Fuse Terminals

Possible Causes:

- Compromised waterproof seal on fuse or holder

- Incorrect terminal material for environment (nickel vs. tin)

- Missing or degraded dielectric grease

- Electrolysis from dissimilar metals

Solutions:

- Replace damaged seals or entire fuse holder

- Switch to tin-plated fuses for marine applications

- Reapply marine-grade dielectric grease

- Install galvanic isolators if electrolysis suspected

Problem: Poor Electrical Contact

Possible Causes:

- Corrosion buildup on terminals despite waterproofing

- Fuse not fully seated in holder

- Worn or damaged fuse holder clips

- Wrong fuse size for holder type

Solutions:

- Clean terminals with electrical contact cleaner

- Remove and reseat fuse firmly

- Replace fuse holder if clips are worn

- Verify fuse type matches holder specification (ATO vs. ATM)

💡 Expert Tip: If you’re experiencing repeated fuse failures in a waterproof installation, the problem is usually not the fuse itself but rather inadequate circuit protection planning or installation errors. Review your entire circuit design and installation quality.

Maintenance Schedule for Waterproof Fuse Systems

Monthly Inspections (Harsh Environments)

- Visual check for obvious corrosion or damage

- Verify all fuses are properly seated

- Check indicator lights or test critical circuits

- Look for water intrusion in fuse panel areas

Seasonal Maintenance (Spring and Fall)

- Remove all fuses and inspect terminals

- Clean any minor corrosion with contact cleaner

- Reapply dielectric grease to all connections

- Test fuse continuity with multimeter

- Replace any fuses showing discoloration or damage

- Inspect and replace worn fuse holder seals

Annual Deep Service

- Replace all dielectric grease with fresh application

- Replace all fuses as preventive maintenance (marine applications)

- Inspect wiring for damage or degradation

- Test all circuits under load conditions

- Document system performance for future reference

⚠️ SAFETY WARNING: Before performing maintenance on fuse panels, always disconnect shore power (boats) or battery power (vehicles). Many fuse panels have constant power even with ignition off.

Waterproof Fuse FAQs

Can I use regular blade fuses in marine applications?

No, you should never use standard automotive fuses in marine environments. Standard fuses lack corrosion protection and will fail rapidly when exposed to saltwater spray, causing circuit failures that can compromise safety systems like bilge pumps or navigation lights. Marine-rated waterproof fuses meeting ABYC E-11 standards are required for Coast Guard compliance and insurance coverage.

What’s the difference between IP67 and IP68 waterproof ratings?

IP67 fuses can withstand temporary submersion up to 1 meter depth for 30 minutes, making them suitable for splash zones and occasional water exposure. IP68 fuses provide continuous submersion protection beyond 1 meter, required for below-waterline installations or equipment that may be fully submerged. For most off-road and above-deck marine applications, IP67 is sufficient; use IP68 for bilge areas or extreme conditions.

Do waterproof fuses fit standard fuse holders?

Yes, most waterproof blade fuses use standard ATO, ATC, or ATM dimensions and fit physically in regular fuse holders. However, you lose the waterproof protection if you don’t use a waterproof fuse holder. The fuse holder connection points are where water typically enters, so pairing waterproof fuses with waterproof holders is essential for effective circuit protection.

How long do waterproof fuses last in marine environments?

Properly installed marine-rated waterproof fuses typically last 3-5 years in saltwater environments before preventive replacement is recommended. Standard automotive fuses in the same conditions often fail within 6-12 months due to corrosion. Actual lifespan depends on factors including direct spray exposure, electrical load cycles, and maintenance quality. Annual inspection and replacement of corroded fuses extends system reliability.

Are waterproof fuses required by law for boats?

ABYC (American Boat and Yacht Council) standards, which form the basis for Coast Guard regulations and insurance requirements, specify corrosion-resistant overcurrent protection for marine electrical systems. While specific “waterproof” certification isn’t explicitly mandated, the practical requirement for corrosion resistance in the marine environment means marine-rated fuses are effectively required for compliance and safety.

Can I install waterproof fuses myself or do I need a professional?

You can install waterproof fuses yourself if you have basic electrical knowledge and proper tools. However, marine electrical work may require licensed marine electrician certification for insurance purposes, and improper installation can create safety hazards. For simple accessory circuits (lights, radios), DIY installation is reasonable. For critical safety systems (bilge pumps, navigation equipment) or if you’re unfamiliar with electrical work, professional installation is strongly recommended.

What causes waterproof fuses to corrode despite their protection?

Even waterproof fuses can corrode if installation is improper or seals are compromised. Common causes include: damaged O-rings on fuse holders, missing dielectric grease on terminals, improper wire terminal crimping allowing water intrusion, electrolysis from dissimilar metals, and UV degradation of plastic housings in direct sunlight. Quality installation practices and regular maintenance prevent most corrosion issues.

Should I use circuit breakers instead of waterproof fuses?

Circuit breakers offer advantages for high-current applications and frequent service needs, as they’re resettable without replacement. However, quality marine-grade circuit breakers cost $30-100 each versus $3-8 for waterproof fuses. Use circuit breakers for winch circuits, anchor windlasses, and other high-load applications where manual reset is acceptable. Use waterproof fuses for most general circuits where cost-effectiveness and proven reliability matter more than resetability.

Quick Reference: Waterproof Fuse Selection Guide

| Your Application | Recommended Type | IP Rating | Amperage Range | Key Feature |

|---|---|---|---|---|

| Boat bilge pump | Marine-rated ATO | IP68 | 10-15A | ABYC E-11 compliant |

| Navigation electronics | Marine-rated ATO | IP67 | 5-15A | UV-resistant housing |

| ATV/UTV accessories | Automotive sealed | IP67 | 5-30A | Vibration-resistant |

| RV exterior lighting | Sealed ATM mini | IP67 | 5-15A | Compact size |

| Jeep winch | Sealed Maxi | IP67 | 60-100A | High current capacity |

| Trolling motor | Marine-rated ATO | IP67 | 40-60A | Continuous duty rated |

| Boat livewell pump | Marine-rated ATO | IP67 | 10-15A | Tin-plated terminals |

Conclusion: Protecting Your Circuits in Harsh Environments

Waterproof blade fuses are essential for reliable circuit protection in marine and off-road applications where standard fuses would quickly fail from corrosion and moisture exposure. By selecting marine-rated or IP67/IP68 sealed fuses matched to your specific environment, installing them with proper waterproof holders and terminals, and maintaining them according to recommended schedules, you ensure your electrical systems remain protected and functional even in the harshest conditions.

Key Takeaways:

- Always pair waterproof fuses with waterproof fuse holders for complete protection

- Choose marine-rated fuses meeting ABYC E-11 standards for saltwater applications

- Install with marine-grade terminals, dielectric grease, and proper sealing techniques

- Inspect and maintain fuse systems regularly, especially in harsh environments

- Never compromise on circuit protection—use properly rated fuses for each application

💡 Expert Recommendation: For critical safety systems like bilge pumps or navigation equipment, consider installing redundant circuit protection with both a waterproof fuse and a downstream circuit breaker. This dual-protection approach provides backup if one component fails and is considered best practice in professional marine electrical installations.

When your electrical systems face water, salt spray, mud, and extreme conditions, waterproof blade fuses provide the reliable circuit protection that keeps you safe, operational, and on the water or trail. Invest in quality marine-grade components, install them correctly, and maintain them properly—your electrical system will reward you with years of trouble-free performance.