A waterproof wire nut is a specialized electrical connector designed to create water-resistant and weatherproof connections in outdoor, underground, or moisture-prone electrical applications. Unlike standard wire nuts, these connectors feature silicone gel sealing, enhanced threading, and protective caps that prevent water infiltration while maintaining secure electrical connections.

Waterproof wire nuts are essential for landscape lighting, outdoor fixtures, underground wiring, and any electrical connection exposed to moisture, providing both electrical safety and long-term reliability in challenging environmental conditions.

What Makes Waterproof Wire Nuts Different from Standard Wire Nuts?

Key Differences Comparison

| Feature | Standard Wire Nuts | Waterproof Wire Nuts |

|---|---|---|

| Water Protection | None – for indoor use only | IP65-IP68 rated protection |

| Sealing Mechanism | Threading only | Silicone gel + enhanced threading |

| Installation | Simple twist-on | Twist-on + cap closure |

| Applications | Indoor circuits only | Outdoor, underground, wet locations |

| Cost | $0.10-$0.25 each | $0.75-$2.50 each |

| Temperature Range | -40°F to 221°F | -40°F to 257°F |

| UV Resistance | Limited | Enhanced UV protection |

| Code Compliance | NEC indoor use | NEC outdoor/wet location rated |

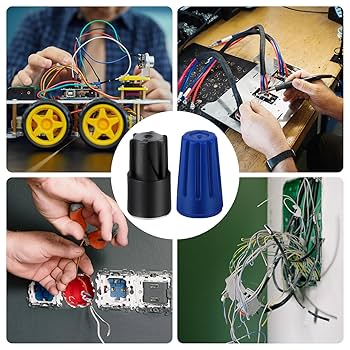

Essential Components

Waterproof wire nuts contain three critical elements:

- Silicone Gel Sealant: Creates watertight barrier around wire connections

- Threaded Connector Body: Provides mechanical and electrical connection

- Protective Cap: Shields connection from direct water contact and UV damage

Expert Tip: The silicone gel is pre-filled in quality waterproof wire nuts. Avoid products requiring separate sealant application, as these often fail prematurely.

How Waterproof Wire Nuts Work

Waterproof wire nuts function through a dual-protection system combining mechanical connection with environmental sealing. When properly installed, the internal threading creates solid electrical contact while the silicone gel displaces air and moisture, creating an impermeable barrier around the wire junction.

Step-by-Step Connection Process

- Strip wire ends to manufacturer’s specified length (typically ¾ inch)

- Insert wires into the connector until they bottom out

- Twist clockwise until tight and wires are fully engaged

- Snap or thread on protective cap to complete moisture seal

- Verify connection by gentle tug test on each wire

Safety Warning: Always turn off power at the breaker before making electrical connections. Verify power is off with a non-contact voltage tester.

Types and Applications of Waterproof Wire Nuts

Common Waterproof Wire Nut Varieties

| Type | Wire Capacity | Primary Use | IP Rating |

|---|---|---|---|

| Standard Gel-Filled | 12-22 AWG | Landscape lighting | IP65 |

| Direct Burial | 10-22 AWG | Underground circuits | IP68 |

| Multi-Port | 3-8 connections | Junction boxes | IP65 |

| In-Line Splice | 2 wires only | Cable repairs | IP67 |

| Grease Cap Style | 10-18 AWG | Marine/high-moisture | IP68 |

Real-World Applications

Landscape Lighting Systems: Waterproof wire nuts are essential for connecting low-voltage landscape lighting fixtures, allowing reliable connections in mulch beds, irrigation zones, and seasonal weather exposure.

Outdoor Security Cameras: These connectors protect power and data connections for security cameras, preventing moisture-related failures that compromise surveillance systems.

Pool and Spa Equipment: GFCI-protected circuits using waterproof connections ensure safe operation of pumps, heaters, and lighting in wet pool environments.

Agricultural Irrigation: Automated irrigation systems rely on waterproof connections to withstand constant moisture exposure and seasonal weather variations.

Waterproof Wire Nut Selection Guide

What Should You Look for When Choosing Waterproof Wire Nuts?

1. IP Rating Requirements

- IP65: Protected from water jets (outdoor fixtures)

- IP67: Protected from temporary immersion (ground level)

- IP68: Protected from continuous submersion (underground)

2. Wire Gauge Compatibility

- Match connector capacity to your specific wire gauges

- Allow for future circuit modifications

- Consider voltage drop in low-voltage applications

3. Environmental Conditions

- Temperature extremes in your installation area

- UV exposure levels and duration

- Chemical exposure (fertilizers, pool chemicals)

- Physical stress from landscaping activities

4. Code Compliance

- NEC wet location ratings

- Local electrical code requirements

- UL listing for safety certification

Professional Selection Criteria

| Priority Factor | Specification to Verify |

|---|---|

| Code Compliance | UL Listed, NEC wet location rated |

| Temperature Rating | Minimum -40°F to 194°F for most climates |

| Wire Capacity | Matches your specific gauge requirements |

| IP Rating | IP65 minimum, IP68 for buried applications |

| UV Resistance | UV-stabilized materials for exposed installations |

Expert Tip: Invest in quality waterproof wire nuts from established manufacturers. Cheap alternatives often fail within 2-3 years, requiring costly troubleshooting and replacement.

Installation Best Practices and Safety Requirements

Professional Installation Guidelines

Pre-Installation Requirements:

- Verify power is off with non-contact voltage tester

- Confirm proper GFCI protection for wet locations

- Check local code requirements for burial depth and protection

Proper Installation Technique:

- Strip wires to exact specification (over-stripping reduces connection strength)

- Ensure wire ends are clean and free of corrosion

- Insert wires completely before twisting connector

- Apply firm, consistent twisting pressure

- Verify secure connection with gentle tug test

- Install protective cap according to manufacturer instructions

Common Installation Mistakes to Avoid

Insufficient Wire Strip Length: Under-stripping prevents full conductor contact, creating high-resistance connections that generate heat and fail prematurely.

Over-Tightening: Excessive force can crack the connector body or push silicone gel out of position, compromising the moisture seal.

Mixing Wire Materials: Never connect aluminum and copper wires directly unless using connectors specifically rated for dissimilar metals.

Safety Warning: Underground installations must comply with NEC burial depth requirements and include proper conduit protection. Consult local electrical codes for specific requirements in your area.

Troubleshooting and Maintenance

Signs of Waterproof Wire Nut Failure

Electrical Symptoms:

- Intermittent operation of connected devices

- Dimming or flickering in lighting circuits

- Complete circuit failure

- GFCI tripping repeatedly

Physical Inspection Signs:

- Visible moisture inside connector cap

- Corrosion on wire ends or connector threads

- Cracked or damaged connector housing

- Loose or easily removable protective cap

Maintenance Recommendations

Annual Inspection: Check exposed waterproof connections annually for signs of moisture infiltration or physical damage.

After Severe Weather: Inspect connections following heavy storms, flooding, or extended freezing conditions.

Landscape Activity: Re-check connections after any digging, landscaping, or irrigation work in the area.

Professional vs. DIY Installation Considerations

When to Call a Professional Electrician

Complex Installations: Multi-circuit outdoor lighting systems, pool equipment wiring, and 120V/240V outdoor circuits require professional installation and permitting.

Code Compliance: Local electrical codes may require professional installation and inspection for certain outdoor electrical work.

Safety Concerns: If you’re uncomfortable working with electrical systems or unsure about proper techniques, professional installation ensures safety and code compliance.

Suitable DIY Applications

Low-Voltage Landscape Lighting: 12V systems typically allow homeowner installation with proper waterproof connections.

Replacement Connections: Replacing failed waterproof wire nuts in existing installations is usually appropriate for DIY.

Garden and Irrigation: Low-voltage irrigation system connections often fall within DIY scope.

Expert Tip: Even for DIY projects, have a qualified electrician verify your work, especially for any connections that will be buried or permanently installed.

Frequently Asked Questions

Can you use waterproof wire nuts in direct burial applications?

Yes, but only waterproof wire nuts specifically rated for direct burial with IP68 protection. Standard IP65 waterproof connectors are not suitable for underground installation and will fail when exposed to continuous moisture.

How long do waterproof wire nuts last outdoors?

Quality waterproof wire nuts typically last 10-15 years in normal outdoor conditions. Lifespan depends on environmental factors including UV exposure, temperature cycling, and moisture levels. Annual inspection helps identify connections nearing replacement time.

What’s the difference between silicone gel and grease-filled wire nuts?

Silicone gel-filled connectors provide superior long-term moisture protection and maintain flexibility in temperature extremes. Grease-filled connectors offer excellent initial moisture protection but may harden over time, especially in cold climates.

Can waterproof wire nuts be reused after disconnection?

Generally no. The silicone gel seal is designed for single-use installation. Disconnecting the connector typically compromises the moisture barrier, requiring a new waterproof wire nut for reliable protection.

Do waterproof wire nuts require special tools for installation?

No special tools are required. Standard wire strippers and basic hand strength are sufficient for proper installation. Avoid using pliers or wrenches, which can over-tighten and damage the connector.

Are waterproof wire nuts compatible with aluminum wiring?

Only waterproof wire nuts specifically marked “AL/CU” or “Aluminum Compatible” should be used with aluminum wiring. Standard waterproof connectors are designed for copper conductors only.

What happens if water gets into a waterproof wire nut?

Water infiltration typically causes intermittent electrical problems, corrosion, and eventual connection failure. Immediate replacement is necessary to prevent safety hazards and further electrical system damage.

Can you paint over waterproof wire nuts for aesthetic purposes?

Most waterproof wire nuts can be painted with exterior acrylic paint once fully cured. Avoid paints containing solvents that might degrade the plastic housing or UV protection properties.

Expert Recommendations and Safety Reminders

Choose Quality Over Price: Invest in UL-listed waterproof wire nuts from reputable manufacturers. The cost difference between quality and cheap connectors is minimal compared to troubleshooting failed connections.

Plan for Future Access: Install waterproof connections in locations that allow future inspection and maintenance. Avoid burying connections without proper marking or access points.

Document Your Installations: Keep records of waterproof connection locations and installation dates to facilitate future maintenance and troubleshooting.

Final Safety Note: All outdoor electrical work must comply with local electrical codes and may require permits and professional installation. When in doubt about code requirements or safe installation practices, consult a qualified electrician to ensure your safety and legal compliance.

Ready to tackle your outdoor electrical project? Choose the right waterproof wire nuts for your specific application, follow proper installation techniques, and prioritize safety throughout the process. Quality waterproof connections ensure reliable outdoor electrical systems that stand up to weather and time.